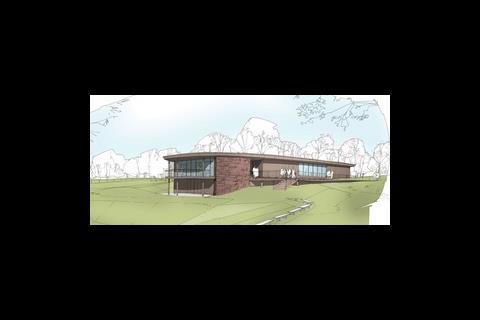

Bicton Arena equestrian centre in Devon has a new management centre as green as its parkland setting, thanks to the client’s commitment to sustainability

The Bicton Arena equestrian centre in east Devon lies within 60 acres of mature parkland.

When the owner decided a new management centre was needed to handle commercial activities the arena also hosts corporate, charity and other sports events it wanted a structure that would sit well within the pastoral landscape.

The parkland is grade I listed, so the project needed to conform to rigorous planning controls. The challenge for services engineer Faber Maunsell, brought on board by client Clinton Devon Estates, was to produce a design that pleased the planners while fulfilling the client’s request for cutting-edge sustainability.

Elliptical in plan, the building is an inconspicuous single-storey structure with an undercroft and basement. It is tucked into the site contours to integrate it into the landscape, an effect enhanced by the sedum roof.

It is not only the appearance of the building that results in a low impact on the environment energy performance is expected to exceed the requirements of Part L 2006 and the project includes the creation of wildlife habitats to increase biodiversity.

“A key requirement for the building was that it should embrace sustainable development and green construction techniques,” explains Iain Potter, Faber Maunsell’s senior mechanical engineer. “The client played a vital role in achieving this. It could have chosen easier and less costly solutions but remained fully committed to sustainability and a minimum carbon footprint.”

The space heating illustrates this determination. The client wanted to use Bicton’s woodlands to establish a sustainable fuel supply. A 50kW woodchip boiler was chosen, which serves low-level heat emitters in the open-plan area and traditional radiators in meeting rooms.

The client has also installed a wood processing and drying facility to ensure the chips are of consistent size and moisture content. This helps the boiler to operate at maximum efficiency with relatively simple controls compared with the sophisticated level of control that would be required for variable-quality fuel. To minimise maintenance requirements, the boiler is fitted with automatic ash removal. The woodchip store has a high capacity and needs to be filled only two or three times a year. Fuel is fed to the boiler using an automatic auger and screw system.

The open-plan office space has exposed soffits to maximise the available thermal mass. The design team has therefore been able to maintain comfort conditions with natural ventilation, making use of external night air to cool the slab. The sedum roof also lessens peaks and troughs in temperature.

Faber Maunsell worked closely with architect Lacey Hickie Caley to minimise solar heat gains by extending the roofline beyond the building with the addition of a limited number of brises soleil.

Air is introduced to the open-plan area through low-level glazing and extracted through high-level rooflights, creating a stack effect to draw warm, stale air out. Windows and rooflights are motor-actuated and linked to a building management system that monitors internal and external temperatures. Ventilation is adjusted by varying the degree of opening.

In the meeting rooms, air is also introduced at low level and extracted at high level into a transfer system that delivers it to the roof vents. Occupants have a manual override facility so they can adjust ventilation rates to suit their preferences. The system reverts to default settings after a pre-set time rather than relying on people remembering to readjust it. The boardroom and IT room also have mechanical cooling, using high-efficiency split-system air-conditioning.

Lighting in the open-plan office areas is predominantly suspended direct/indirect luminaires using T5 linear fluorescent lamps. These uplight the soffits to create a bright environment and minimise contrast between the ceiling and walls, while the downward light component maintains design illuminance levels on the working plane.

Each luminaire is individually addressable and linked to a DALI-based system (Digital Addressable Lighting Interface) to provide flexibility for reconfiguration in the event of layout changes. The system incorporates photocells and daylight linking to make maximum use of the high level of natural light within the building.

The client worked closely with the design team throughout the project, which significantly contributed to the success of the new management centre. The result is a building that performs well in its own right and makes the most of its natural environment, rather than relying on sophisticated technologies to offset the failings of a compromised design.

Project details

Architect: Lacey Hickie Caley

Main contractor: Dean and Dyball

PM/QS: Norman Rourke Pryme

Structural engineer: Faber Maunsell

Services engineer: Faber Maunsell

M&E installation: Beale and Cole

Source

Building Sustainable Design

No comments yet