Using a building in a central London development as an example, Leo Cheung and Mirko Farnetani of Sturgis Carbon Profiling look at facade systems to explain how embodied and whole-life carbon can be reduced through simple design and specification decisions at little additional cost

01 / Introduction

A building’s facade is the first, and often only, impression we have of a building. It can be a key design feature with multiple functions: linking the internal environment to the external; communicating an architectural concept; or creating an identity for the occupants. Consequently, a building’s facade can often be replaced before the end of its design life, resulting in an unwelcomed increase in whole-life carbon (including deconstruction and disposal impacts, and the embodied carbon of the new facade).

Given this potentially short replacement cycle (compared to design life), it is all the more important to minimise the embodied carbon of facade systems. In this article, we discuss various ways to reduce the embodied and whole-life carbon of facades without significant impacts on appearance or cost.

Methodology - Whole-life carbon assessment

The whole-life carbon (WLC) methodology used in this article follows the European and British standards (CEN/TC 350 and BS EN 15978 respectively). WLC analysis ensures that all product-life stages, from product manufacture (stage A, modules A1-A3), to construction (modules A4-A5), to use (stage B), to end-of-life (stage C), are considered when quantifying carbon costs, and when assessing options for carbon savings.

Given our focus on recycled aluminium later in this article, it is worth noting that to avoid double counting, the WLC standards include recycling benefits in stage A (“product stage”) and not in stage D (“re-use, recovery, recycling potential”), the latter being out-of-scope. However, this should not preclude the consideration of recyclability when it comes to material selection, as discussed later.

02 / Facades

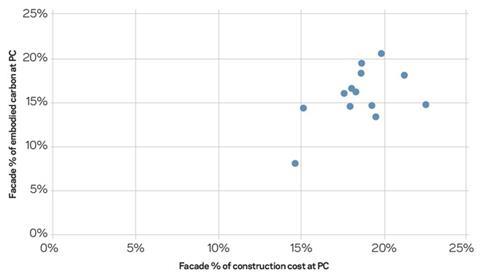

One of the most critical factors in whole-life carbon analysis is the replacement/refurbishment cycle. Building systems (such as the facade) are often replaced before the end of their operational lives, due to the disconnect between design-life, replacement cycle and lease cycle. This can be further complicated in mixed-use buildings, where different occupants have different lease lengths and different expectations of when facades/windows are replaced; and by less-flexible modern curtain wall designs, that need to be replaced on a much larger scale than a facade with “punched” windows. Some of these whole-life aspects were discussed in the previous article (May 2012), and while these remain critical, the focus here is on the low-carbon choices that can be made whenever a facade is specified. These choices can minimise the embodied carbon for each replacement/refurbishment cycle. To put all this into context, figure 2 shows that facade systems can account for a significant proportion of a building’s embodied carbon (13-21% range, average 16%), and construction costs (17-22% range, average 19%), at practical completion. Additionally, the specification and procurement of a building’s facade can have a long lead-time (40+ weeks is typical). This can limit flexibility, so early discussions around low-carbon facade options are important. This article discusses one of the most common and carbon-intensive materials used in facades, aluminium; it compares embodied carbon for different types of aluminium, and then estimates the potential carbon savings that can be achieved for curtain walling systems through various specification changes.

03 / Material elements of facades

A. Focus on aluminium

Aluminium, a commonly used facade material, has an energy intensive production process and is responsible for around 1% of global greenhouse gas emissions. However, since the carbon intensity of aluminium can vary 20-fold (from virgin to recycled aluminium), the embodied carbon of aluminium-components can be greatly reduced through some simple design and specification decisions.

A.1. Aluminium - a precious metal?

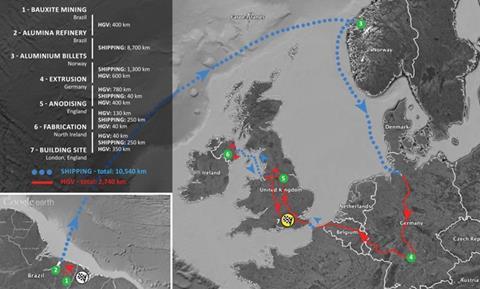

The global consumption of aluminium is expected to triple or quadruple through to 2050, and although recycling rates continue to improve, much of this demand will need to be met through carbon-intensive virgin aluminium. Within Europe, 65% of the aluminium consumed is produced outside the EU Emissions Trading Scheme, so it is important to consider the global aluminium supply chain. Figure 3 maps out an illustrative example of virgin aluminium production: Bauxite (labelled 1 in figure 3) is extracted from a mine in Brazil and transported by road to a refinery where it is converted to alumina (2). The alumina is shipped to Norway where it is smelted into aluminium billets (3) via electrolysis. The billets are extruded (4) into profiles in Germany, anodised (5) in England, and then fabricated (6) into curtain wall frames in Northern Ireland. Finally, the frames are delivered to the construction site in London (7). The most significant step from a carbon perspective is the electrolytic smelting process, which uses a large amount of electricity and accounts for around 60-90% of emissions. The location of the smelting plant, and consequently the mix of energy-sources of the electricity used, is thus a key factor in emissions. The energy-mix can range from coal-dominated (80% coal in China - the world’s largest producer of virgin aluminium), to renewable-dominated (90% hydro in Latin America). The careful selection of an aluminium supplier can therefore greatly reduce the embodied carbon of the purchased product. This “green demand” can also provide a market-signal to aluminium producers and incentivise investment in low-carbon production technologies, recycling and the circular economy, thus helping to drive the decarbonisation of the aluminium sector in the long term.

A.2. Aluminium - Potential carbon savings

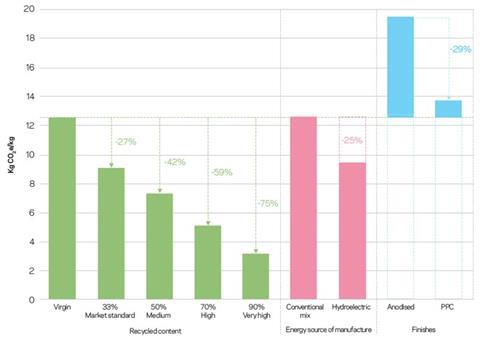

The effect of some common specification and procurement choices on the embodied carbon of 1kg of aluminium is shown in figure 4. One of the simplest ways to reduce aluminium’s embodied carbon without altering its appearance is to use aluminium with a higher recycled content (RC). Compared with virgin aluminium, increasing the %RC can reduce the embodied carbon by around 42% for medium RC (50%RC), or by 75% for very-high RC (90%RC). Sourcing aluminium produced using renewable hydro-energy (rather than a conventional energy mix) can reduce embodied carbon by 25%, again without altering appearance.

Finally, the choice of aluminium finish will alter the embodied carbon, but this may have an effect on appearance. A Polyester Powder Coated (PPC) finish can save approximately 29% embodied carbon compared with an anodised finish. Some large paint manufacturers now offer an “anodised-look” PPC finish, which offers much lower embodied carbon without compromising the aesthetic. The finish also affects recyclability at end-of-life. Anodising aluminium changes its chemistry and makes it much more expensive and complex to recycle compared with PPC. Although recyclability is out of scope for the whole-life-carbon calculations (stage D), anyone following circular economy principles would do well to avoid anodising aluminium.

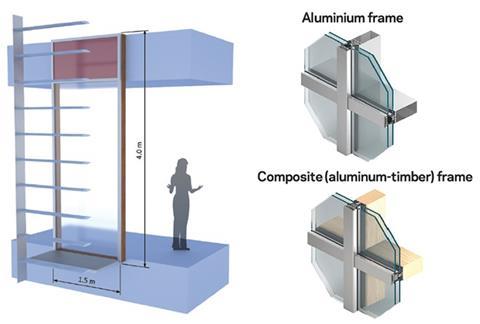

B. Timber/composite frames

An effective way to reduce the embodied carbon of a curtain wall frame is to move from a fully aluminium construction, to composite aluminium-and-timber frame. Timber has lower embodied carbon than aluminium and the benefit of carbon sequestration during tree growth. It is important to note however, that timber should be disposed of appropriately at end-of-life (recycling, reuse or combustion for energy or heat). If the timber is sent to landfill, the methane emitted during decomposition can abate much of the carbon benefits.

04 / Whole-life carbon (WLC) analysis of facade systems

For comparative purposes, we will use a case study based on an actual, and typical, development in central London. The 6,000m2 facade consists of: a unitised aluminium-framed double glazed curtain wall; a glass and aluminium spandrel; and 9x 250mm aluminium louvres per unit - see figure 5. The research was conducted with assistance from Argent LLP and Bennetts Associates. The WLC of the curtain wall systems and louvres was calculated separately using the European/British standard methodology, assuming a 60-year lifetime and a 35-year replacement cycle.

05 / Curtain wall systems - WLC analysis

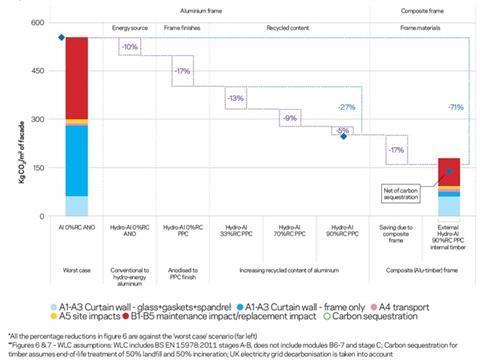

The WLC per m2 of facade for the “worst-case scenario” (fully anodised, virgin aluminium frame, produced using a conventional energy mix) is shown on the left of figure 6. The potential percentage reduction in WLC for each measure is shown in turn, starting with the energy source, then the aluminium frame finish, the recycled content of aluminium, and finally the option of a composite (aluminium-timber) frame. The far right of the diagram shows the WLC of the “best-case scenario” - a composite frame with highly recycled PPC-finished aluminium produced using renewable energy.

If the appearance of the facade cannot be changed, the WLC can still be significantly reduced by 54% against the “worst case”. Our analysis (see figure 6) shows that 10% of this reduction comes from sourcing hydro-produced aluminium, 17% from specifying a PPC finish with an anodised look, instead of an anodised finish, and a further 27% reduction is achieved by using aluminium with 90% recycled content.

If the appearance can be changed, specifying a composite aluminium-timber frame provides a further 17% saving, giving a total WLC reduction of 71% against the worst-case scenario.

Curtain wall systems - other considerations

Other factors to consider which could reduce the WLC include: a) the high road transport emissions associated with heavy glazing elements - using local sources will reduce emissions; and b), the material used in the facade fixing system. Stainless steel is the standard material for fixings, however, galvanised steel could be used and is almost four times less carbon intensive for the same weight. If the long-term performance of galvanised steel fixings can be proven, this offers potential embodied carbon savings.

06 / Louvres - WLC analysis

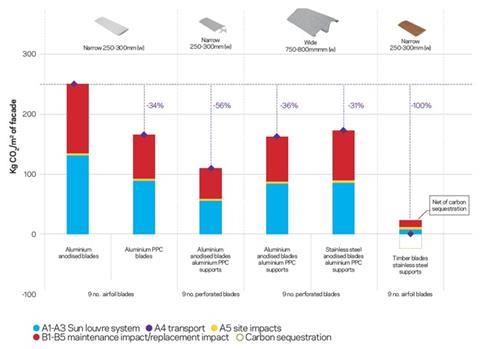

The WLC of various louvre options is shown in figure 7 below. The baseline specification of 9 x 250mm anodised aluminium airfoil blades is shown on the left.

If the appearance cannot change, a 34% reduction in WLC can be achieved through specifying an anodised-look PPC finish.

If the appearance of louvres can be altered, there is greater potential to reduce the WLC: using perforated blades offers a 56% reduction; changing the design and altering the size and number of blades (to 3 x 750mm blades) offers a 36% saving; and using stainless steel blades in this latter configuration reduces WLC by 31%.

The greatest WLC savings can be achieved if timber blades can be specified. This will result in a 100% reduction (including carbon sequestration), however, as previously mentioned, care must be taken to ensure appropriate disposal at end-of-life.

07 / Cost impact - Curtain wall systems

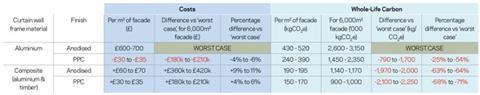

We obtained budget quotes for the various curtain wall options. The variables that affected the cost were: a) the finish of the aluminium (anodised vs PPC); and b) the frame material type (ie. fully aluminium or composite with timber). The recycled content (RC) of aluminium and the energy source of manufacture (conventional mix vs renewable) did not affect the cost.

The middle columns in table 1 below show the approximate costs for aluminium and composite frames in anodised and PPC finishes, and the right-hand columns show the WLC numbers. The WLC ranges represent different grades of aluminium (varying %RC and energy source of manufacture).

If a full-aluminium frame is required, table 1 shows that a PPC-finished aluminium frame can be approximately 5% cheaper than the “worst case” anodised-frame, while also offering up to a 54% reduction in WLC if highly recycled, renewable energy-manufactured aluminium is specified. It makes environmental sense to specify the highest-recycled and renewable energy-manufactured aluminium and it makes economic sense to specify a PPC finish. With anodised-look PPC finishes now available, it makes little economic or environmental sense to anodise aluminium. Here, the low carbon options are also the low-cost options.

The greatest carbon savings (up to 71%) are achieved by selecting a composite (aluminium-timber) frame, although this will cost more than the ‘worst case’ scenario.

If the anodised aluminium exterior is retained, the composite frame is 9-11% more expensive. However, this can be reduced to only a 4-6% cost uplift, or £180k-£210k for our case study, by specifying the cheaper PPC (anodised look) finish.

08 / Conclusions and recommendations

A building’s facade represents a significant share of a building’s total embodied carbon, and construction costs, at practical completion. It can be one of the first building systems to be specified and procured, and it may also be refurbished or replaced before the end of its design life. It is therefore vital to discuss low-carbon options early in the procurement process to ensure that the embodied and whole-life carbon of the facade systems are minimised. Even for such a visible part of the building, this need not be a difficult conversation, since some straight forward procurement decisions can save money and significant amounts of carbon without altering the appearance of the building. An example of this would be specifying PPC-finished aluminium with high recycled content, made using renewable energy.

If some changes to appearance are acceptable, using timber in place of aluminium (ie for the curtain wall frame and for the louvres) offers the greatest carbon savings for little extra cost.

It is also important to consider aspects beyond the scope of the whole-life carbon calculations, such as recycling and re-use. For example, specifying a polyester powder coated finished aluminium rather than anodised aluminium means that the aluminium is more recyclable at end-of-life. This will contribute to future stocks of low-carbon recycled aluminium, and will help sustain aluminium’s circular economy in the long term.

No comments yet