An immersive gallery with a theatrical facade is taking shape in central London on the Outernet site at St Giles Circus, but it is under the ground that the real drama has taken place, with an enormous music venue carved out amid a tangle of tube tunnels, and one historic building temporarily lifted out of place

From outside the hoardings of the Outernet London construction site, at the heart of the West End, it is impossible to appreciate either the scheme’s full extent or the complexity of the groundworks that underpin it. The site has returned to life after falling suddenly silent at the end of March, and is running at nearly 80% capacity now that contractor Skanska has got to grips with the challenges of socially distanced working. Completion is still scheduled for this year, albeit later than the original date of the end of June.

The mixed-use scheme, being developed by owner Consolidated Developments, will deliver a range of facilities, crowned by a multimedia gallery and entertainment venue that is said to be the latest in fully immersive destination venues. But this gold and black building with its striking louvred facade, set in the site’s north-west corner, is the tip of the iceberg of this scheme, which relies heavily on complex foundation works.

Outernet is part of a wider, £150m scheme known as the St Giles Circus project, covering some 25,000m2 of development in a block bounded by Denmark Street, Charing Cross Road and St Giles High Street. Andrew McEwan, associate at scheme architect Orms, says the client’s brief was unusual in having a high-level vision but with few specific requirements. “They wanted to consider how they could reimagine the site, and they put their faith firmly in the design process,” he says.

Keeping a link to the area’s music industry roots was an important element of the brief, as was creating as much active frontage as possible. The porosity of the site has been improved with the reinstatement of Denmark Place, an alleyway that cuts through the middle of the St Giles Circus site and will make it easier to appreciate the full scale of the development. The historic buildings on Denmark Street appear largely unaltered, although they have been fully renovated and remodelled internally, and the facade on St Giles High Street has been retained, with new buildings constructed behind it. Hence from the outside, the site seems relatively modest.

Clive Fussell, director of project engineer Engenuiti, immediately dispels this perception, revealing that one of the asks in the client brief was to build “the biggest basement possible” beneath the site. This will be a 2,000-person capacity music venue housed in an acoustically isolated structure below the new buildings.

Working around the tube tunnels

The proximity of Tottenham Court Road tube station, which is already served by the Central and Northern lines and will be on the forthcoming Elizabeth line, is both a blessing and a curse for the scheme. It is predicted that 200,000 people will use the remodelled station each day once all lines are operational and the days of social distancing have passed, but the presence of the tunnels through which these paying customers will arrive created a ground‑engineering headache. “The transport infrastructure brought its own challenges,” says Fussell.

Construction of the Elizabeth line, with its extended gestation and delivery, played a part. Plans to remodel Tottenham Court Road station for the arrival of the new line included the construction of a new entrance right in front of the Outernet development. Escalators were to be built directly under the western edge of the scheme for improved access to the Northern line, and initially London Underground intended to purchase the land to carry out this work. But a leasing arrangement for the duration of the box structure’s construction allowed escalators to be installed without affecting the subsequent build.

Plans were made to straddle both the escalator box and the Elizabeth line tunnel, which was due to be driven under the site in 2013. A £7m works contract carried out in 2010, even before submission of the planning application for the main part of the scheme, saw seven 64m-deep, 2m-diameter piles installed close to the perimeter of the escalator box as support for the future building. In some places these piles come within a metre of the Northern line tunnels.

With the Elizabeth line tunnel, Fussell explains that the challenge lay not just in maximising space to make the underground entertainment venue as large as possible, but also in addressing the impact this could have on the condition of the ground. With the removal of a significant volume of overburden, heave was an obvious risk that had to be addressed. This involved installing a series of heave-retention piles to depths of up to 48m. “Essentially the purpose of these is to hold Crossrail down,” Fussell says.

These tension piles are heavily reinforced and their construction posed practical challenges, as Paul Roberts, Skanska project director, explains. “We had to splice the reinforcement cages in 12m sections,” he recalls, because their total length of 48m was too long to be fixed in single lengths. The usual challenges of working in a high-profile city-centre location were multiplied on this project by the complexity of the building methods used, which meant the site was little bigger than the final building footprint, and by the extensive nature of the temporary structures required.

Moving the historic Smithy

Tucked behind the streetscape of Denmark Street – the UK’s Tin Pan Alley, as it has been dubbed – sits a small, 17th-century building that was originally a blacksmith’s forge. As a rare survivor in central London, the Smithy (pictured below) has great heritage value, and as part of the former 12 Bar Club is also significant to the music industry. It forms part of the Outernet London scheme as an entrance to the underground auditorium, and the initial plan was to leave it in place throughout construction.

However, it also sits right over the Elizabeth line tunnel alignment, and the mitigation piling that was proposed for the tunnel had to be applied across the whole development site. Calculations revealed that installing these works with the Smithy in place risked it being damaged by differential settlement, so temporary relocation was agreed to be the best solution.

A transfer structure had to be created underneath the building for the relocation, and this was designed to function also as a permanent slab when the Smithy was returned. The building was braced by steel beams tied back to the slab to keep it secure during the move.

The main challenge was the size of the lift – with the slab included it weighed in at 150 tonnes, and to move it by 25m was only just within the capacity of the crane – a 750-tonne mobile crane was required. The first operation took place in August 2017, with the process being reversed just over a year later, in October 2018. While the Smithy was out of the way, tension piles could be installed along the route of the Elizabeth line tunnel before the building was returned.

Building up while digging down

Roberts explains that Skanska was first appointed in 2015 for the pre-construction services agreement, the work for which took two years to complete because of delays caused by archaeological excavations and funding issues. The main contract work started on site in 2017 with piling operations. To accelerate the overall programme, top-down excavation has been progressing in parallel with above-ground erection of the steel-framed buildings.

To facilitate this, plunge columns were used to support the above-ground structure – these are bored piles into which steel sections are cast for effective load transfer. Some of these were only necessary as temporary works supports, and were subsequently removed.

The main floor slab includes 34m-long beams to span across the 2,000-capacity underground venue space. This acoustically isolated basement is described by Ian Hamilton, associate at Engenuiti, as “a box within a box”, consisting of a steel frame structure with metal deck composite concrete floor and roof slab, which was assembled within the main reinforced concrete frame basement box.

Striking the right balance for the acoustic isolation was tricky, Hamilton says, given that the venue will host many different types of events. It was necessary not only in order to ensure train noise would not affect performances but also to prevent vibration in the case of lively events. “It was all about finding the sweet spot,” Hamilton says.

While top-down construction shortened the build programme, it meant that access to the excavation below the floor slab was limited to a series of “mole holes” through which spoil was extracted and steelwork subsequently lowered. “Steel beams had to be lowered into the hole and placed on a ‘roller skate’ to allow them to be manoeuvred into the space,” explains Neil Keogh, senior project manager at Skanska.

The steelwork for the auditorium box roof, which measures 28m x 24m, was assembled on the basement slab and then raised into position by jacks so that the rest of the steelwork for the box could be erected below it.

The gallery building

Above ground the two new steel-framed buildings housing the multimedia gallery, boutique hotel, retail and restaurants reached structural completion last year and are currently being clad and finished. The most striking of the two is the one housing the gallery, with its 22 retractable louvres that extend over three storeys, on two sides of the building. Orms’ McEwan explains that the “semi-internal, semi-external” space in the 16m-high, four-storey-high gallery is designed so that it can be made fully immersive, with 1,478m² of high-quality LED screens covering all the walls and the ceiling. Those on the ceiling and two of the walls are fixed, and there are two retractable screens that can slide into place as required.

The brass-coloured louvres that form the two walls are 9.5m high and each weigh 2.5 tonnes. They are designed to pivot and open along tracks to reveal the space within, like theatrical curtains. The louvres – which are the result of a four-year collaboration with specialist facades subcontractor Frener & Reifer – are top-hung and each have three motors, two to drive the lateral movement and one for the pivot, says McEwan. Controlling deflection of the structure could have been a problem for these elements, were it not for the fact that the steel frame was already designed as an extremely stiff structure.

The reason for the robust design comes back to the underground obstructions: the north-west column of the steel frame sits directly above the escalator box, and was not permitted to be used for load transfer. It is essentially a wind brace, says Engenuiti’s Hamilton. “There is a 50mm gap between the base of the column and the ground,” he reveals, “and it is hung from two huge trusses cantilevered from the adjacent columns.”

Of these, the largest is 25m long and weighs in at 35 tonnes. They were brought to site in pieces and assembled and erected over a two-week period in October 2018 using a Liebherr 1500 mobile crane. The slew of the crane had to be restricted due to the proximity of the glass box entrance to Tottenham Court Road underground station.

The opening facade of the gallery building is supported on a 22m-long, 34-tonne beam on thermally broken sliding bearings. The black granite cladding and louvres are now in place, and Roberts says the job is nearly 95% complete. The pause in work and the time needed to institute new ways of working to comply with social distancing measures have inevitably delayed completion.

Roberts says Skanska is currently negotiating an extension of time with the client and has allowed the gallery fit-out contractor early access to keep the job moving forward as quickly as possible. When work is finally complete, the finished building with its gold mechanical curtains and immersive gallery will be a suitably theatrical tip to the underground iceberg.

How Skanska adapted to the pandemic lockdown

Additional reporting by Thomas Lane.

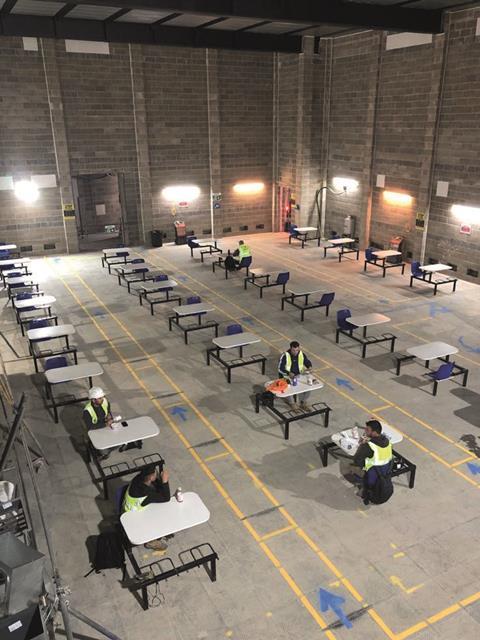

When prime minister Boris Johnson announced the lockdown on 23 March, Outernet contractor Skanska took the decision to stop all site-based work. With 350 people having been on site each day before lockdown, the only people left on site were a couple of security personnel and a handful of others needed to keep systems such as pumps running. “It took a week to review our procedures on site and work out how to meet the requirements in terms of social distancing and travel,” explains Paul Roberts, Skanska project director. “During the second and third week we developed the welfare, the one-way system, signage and the booking in procedures.”

Before reopening the site, Roberts invited the managing directors of the subcontractors to review the new measures. “The feedback we got was overwhelmingly positive given what we had to do in such a short space of time,” he says.

Workers started returning in mid-April. Strict controls including an electronic booking system were introduced so that Roberts can know who is coming in each day. The number of cleaners was increased and shifts for use of the canteen were introduced. Only one person can sit at tables that normally seat four, with workers bringing in their own sandwiches.

Roberts says the site workers have been happy with the new arrangements. “Generally the guys want to come back to work as they are mostly self employed. They understand the rules and how serious this is so they are very receptive to it.”

A road running around the site perimeter was initially used for car parking, but as the number of workers increased the space had to be reclaimed for site operations. Fifty places were secured at a nearby NCP car park, with Skanska picking up the tab. Roberts says getting to work never posed a problem. “I was surprised by how many people walked and cycled in. There never seemed to be an issue with people getting into work,” he explains. Management teams continued to work from home to take pressure off site facilities.

There are now 220 people on site, which Roberts says is 80% of the original number as management staff continue to work from home. He explains that some activities could not be done safely at first because they involved several people working in close proximity – moving large cladding panels, for example. This has been resolved by the relaxation of the 2m distancing rule and the use of PPE. To help make up for lost time Roberts has obtained permission from Camden council to extend site working hours until 9pm each day. These extra hours are used for work on the stairs and cores that cannot be done during the day as these are part of the one-way system around the site.

Project team

Main contractor Skanska

Architect Orms

Structural and civil engineer Engenuiti

Client Consolidated Developments

Piling subcontractor Cementation

Basement and concrete subcontractor Careys

Steel fabricator Severfield

Building services engineer and acoustician Buro Happold

Geotechnical engineer Donaldson Associates (now Cowi)

Project manager GVA Second London Wall

Peer review Arup

Facade subcontractor Frener & Reifer

Stone supplier Szerelmey

No comments yet