By thinking fabric first we can make strong inroads towards net zero writes Paul Barrett, head of product management, ROCKWOOL UK

While conversation around the UK’s net zero strategy continues to be dominated by – aside from its lawfulness – discussions on how we can roll out energy saving technologies effectively and our commitment to a transition to renewable energy, the fabric of our buildings continues to be overlooked.

What’s forgotten is the cheapest, cleanest, safest energy is the energy we don’t use. To cut greenhouse gas emissions in line with the Paris Agreement, help households reduce their energy bills, and bring about a greener and more sustainable environment, we must address building performance, fabric first, and place more emphasis on how buildings perform not just when built but beyond.

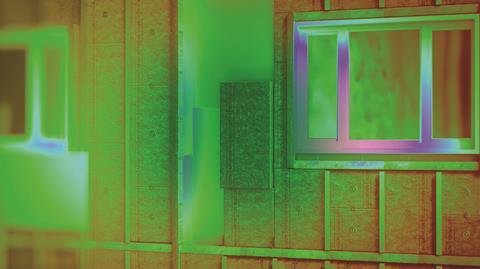

While changes to Approved Document L in England, place greater scrutiny on closing the gap between designed and as-built performance, performance gaps often occur in areas that can’t be seen. As such, we need more stringent monitoring of the build quality and, in particular, ensuring properly-installed, durable insulation is used to ensure the required performance is achieved and continues to do so.

Continuity for compliance

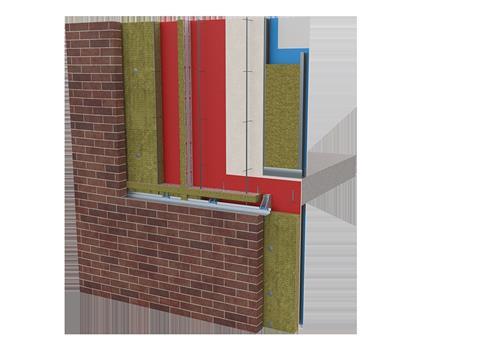

The first step in achieving this designed performance is to be certain that insulation is fitted contiguously and without gaps. Stone wool insulation makes this process easier as it is highly pliable so can be closely friction fitted to frames, without the need for impractical levels of precision cutting. This simplicity minimises the margin for error, supporting reliable and effective thermal performance that reduces thermal bridging.

This process also applies to abutments between insulation boards, another area that can be prone to thermal leakage. The composition of stone wool insulation allows individual slabs to knit together to create a seamless fit and the workable nature of stone wool insulation supports the delivery of designed U-values.

For continuing performance, dimensional stability is key. Building materials naturally expand and contract over time which can lead to the formation of gaps and voids. Stone wool maintains its shape and properties over time across a wide range of temperatures, and has the resilience to accommodate building movement when fitted under compression. It has a proven ability to provide consistent performance – even up to 55 years[1] – without a drop in its thermal properties and because of its high density semi rigid composition, it will not slump in the cavity.

Innovation in insulation

The UK’s drive to net zero must also be supported by building product manufacturers, leading a charge with innovation that delivers on thermal performance in reality as well as the commercial factors that can sometimes be barriers to specification.

This is something we wholeheartedly focus on at ROCKWOOL and this year released our first products featuring NyRock® technology, a patented production process that creates the most thermally efficient stone wool insulation currently available in the UK and Ireland.

NyRock Cavity Slab 032 is one solution in the range, which is BBA certified for full and partial fill masonry cavities.

With a 0.032 W/mK lambda value, it provides a 13% improvement in thermal performance over the existing/standard stone wool cavity slab, plus space saving benefits.

NyRock Cavity Slab 032 can achieve 0.18 W/m²K with a thickness of 150mm, depending on construction type – 25mm thinner than standard stone wool cavity products within the same build up.

Likewise, NyRock Rainscreen 032 and Frame Slab 032, our solution for ventilated cladding systems and sealed structures, can typically save around 15mm on the wall thickness compared to traditional stone wool products.

Applying that saving over a 22m x 22m building of nine storeys, for example, it can yield an extra 99 square feet of usable or profitable floor space[2].

While climate change and the need to reduce energy consumption mean thermal efficiency is the primary driver for insulation choice, thermal performance should not be seen in isolation or focused on in detriment to other critical factors that affect the long term safety and comfort of buildings. The benefits need not be mutually exclusive.

As stone wool insulation is manufactured from naturally occurring volcanic rock, it has an innate non-combustibility, meaning that many stone wool solutions achieve a European Reaction to Fire Classification of A1 - the highest possible rating. What’s more, the dense, non-directional fibre orientation of stone wool and its open porous structure, traps sound waves and reduces sound energy for acoustic performance.

Heating buildings equates to nearly a quarter of UK emissions[3]. By thinking fabric first, focusing on all the needs of building users, and reducing the gap between design, build as well as long term performance, we can make strong inroads towards net zero and ultimately deliver better buildings for future generations.

[1]FIW (German test and research institute), Durability Project Mineral Wool, 2016

[2]Based on 22m x 22m building with nine storeys and allowing for 20% load factor

[3]UK Government, Heat and Buildings Strategy

No comments yet