Engineers seeking to cool an overheated ticket office at Tower Bridge found the answer beneath their feet

Sometimes solutions to difficult engineering problems can turn out to be surprisingly simple. That was certainly the case when the City of London approached Bere Architects for help to moderate the overheated interior of the ticket office at Tower Bridge. The fully glazed ticket office, which stands on its north pier, was built in 1993. The transparency of the design was intended as a light touch on the grade-I-listed bridge, which dates back to 1894. However, the lack of insulation meant the office suffered from poor thermal performance, making it vulnerable to extremes in temperature.

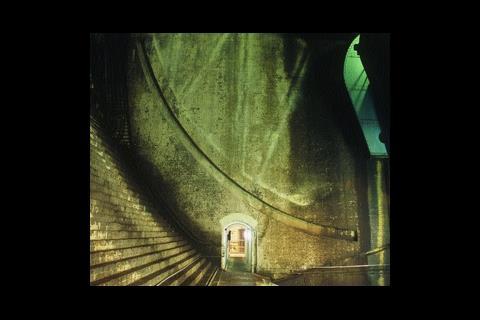

Bere’s first step was to improve the building envelope by making the facade more airtight, fitting integrated shading and filling in a rooflight to cut down solar gain. But these measures alone were not enough to avert the need for cooling. Architect Justin Bere came up with a solution using an untapped source of cooling in the depths of the bridge – the bascule chamber. This is a brick compartment built in the shape of a quarter cylinder, with a width of 13.5 m and a swept radius of 12 m, that houses the huge counterweight used to raise the bridge. Extending through the water line and 5 m into the riverbed, the chamber’s air temperature is stable and remains below 18ºC throughout the year.

When he first experienced these significantly cooler conditions, Bere realised their potential to help the overheated ticket office. After early discussions with services consultant Max Fordham, who saw its potential, Fulcrum Consulting was appointed to carry out design development and implement the idea.

The system is straightforward. Air is drawn from deep inside the chamber by a fan previously used for other purposes at the bridge. The air is distributed by ductwork with sound attenuation to a series of ducts incorporated in the bespoke sales desk designed by the architect. There are four outlets on the staff side of the desk, with aircraft-cabin style individually controllable nozzles, and eight vents built into the public side.

Concerns were raised at the design stage about the quality of the air in the bascule chamber, given the damp conditions and the heavy traffic above. Enviros Consulting was brought in to carry out tests and over a three-month period it analysed the air for its concentration of nitrogen dioxide, particulate matter and micro-organisms. Mark Broomfield, technical director of Enviros, says the results were all within the government guidelines.

The concentration of nitrogen dioxide was below the government maximum of 40 micrograms/m3, measuring just 7.4 micrograms/m3 close to the duct supplying the ticket office. Particulate matter was also below the guidelines and tests for fungal spores showed no more than 440 colony forming units/m3, compared with a government guideline of 1000.

Richard Shennan, director at Fulcrum, is confident the cool air from the bascule chamber will be enough to keep conditions acceptable throughout the year. Overall the mechanical vent solution uses less power than a mechanical cooling system, leading to a reduction in electricity consumption. At grid connection carbon intensity this is estimated to deliver a saving of up to 500 kg of CO2 emissions over the year. A small amount maybe, but combined with the low impact of the design in terms of the changes required, not bad really.

Source

Building Sustainable Design

No comments yet