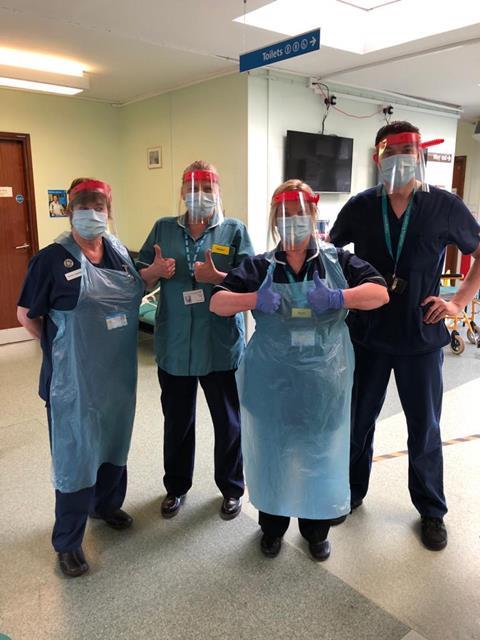

PPE equipment being manufactured using 3D and laser printers

Two employees from WSP are helping produce hundreds of protective face masks every week using 3D and laser printing techniques.

The pair are among dozens of volunteers across the UK answering the call to produce PPE for NHS workers and those in care homes.

Peter Townsend, BIM model manager at WSP, is producing around 100 face masks a week using 3D printers and is part of an initiative called 3DcrowdUK, which aims to make 50,000 units a week.

And Tim Neobard, project controls manager in WSP’s rail division, is using lasers to manufacture face masks as part of a collaboration with Essex community workshop Hackspace.

He said the four lasers he is working on are capable of producing more than 30 face masks every hour and has so far produced more than 5,000 shields out of a 13,000 target number.

Townsend added: “Knowing that there was a demand for essential supplies and being in a fortunate position to have the equipment solution at hand, as engineers, it is in our DNA to help in times of need.”

Last week, Building reported that 20 architect practices had clubbed together to use thousands of 3D printers to help make face visors for the NHS.

The Industry Prints initiative, led by HTA Design and HOK’s London Studio, is a co-ordinated effort to manufacture face visors to exact NHS specifications and distribute them directly to front-line workers. Other firms working on the initiative include Foster + Partners, PLP and Hopkins.

Building has launched its Proud to Help campaign this week to highlight all the work construction is doing to support the country’s public services, critical works and supply chains, as well as setting it back on the road to recovery. Contact newsdesk@building.co.uk with the subject line ‘Proud to help’ or via LinkedIn or Twitter @BuildingNews with #ProudtoHelp stories

No comments yet