Move comes after delays to government design competition

Rolls Royce has mothballed its plans to build a £200m factory for manufacturing parts for small modular reactors (SMR) following delays to a government design competition.

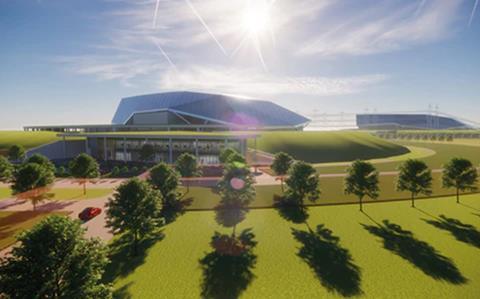

The firm had planned to build two factories to support its SMR programme, one for manufacturing heavy pressure vessels and the other for assembling modular units.

Rolls Royce said it has now “prioritised” work on its modular assembly factory and would source heavy pressure vessels, which are key components in the mini reactors, from the supply chain.

It comes after Great British Nuclear, the government body tasked with driving a new generation of nuclear power plants, pushed back a decision on where the first SMRs would be built until the end of the year.

Rolls Royce is among six companies that have been shortlisted in a competition announced last July for providing SMR prototypes, with other firms including GE-Hitachi, Holtec Britain and Nuscale.

A spokesperson for Rolls Royce said: “Rolls-Royce SMR is a factory-built solution and will need to use a range of facilities, managed by ourselves and by our supply chain.

“We have prioritised work on our Modules Assembly and Test Facility, where we will bring together components from the supply chain for fabrication into modules which are then taken to site for assembly into the finished power plant.

“Our unique modularisation approach is key to our success and, therefore, our efforts are focused on this facility and identifying the best site to support our deployment at pace.

“The components that would be produced by a heavy pressure vessels factory can be sourced from the supply chain in the short term but, with a sufficient fleet commitment in the UK and overseas, there is further opportunity for investment in additional factory infrastructure.”

A government spokesperson said: “Our world leading SMR competition aims to be the fastest of its kind, helping secure billions in investment for the UK, meaning cleaner, cheaper and more secure energy in the long-term.”

Earlier this month, Kier announced it had signed a deal with two nuclear specialists, X-energy and Cavendish Nuclear, to work on proposals for SMRs.

The team is set to develop a fleet of high-temperature gas-cooled ‘pebble bed’ reactors designed to be partly prefabricated in factory conditions and transported to site for assembly, allowing for a construction time of three to four years.

There are plans for around 40 in the UK, each of which can produce 200MW of high temperature heat and steam for industrial applications as well as 80MW of electricity.

No comments yet