Manchester City Council set out to eliminate stuffy classrooms by testing whether mechanical ventilation regulates CO2 levels more effectively than natural ventilation. Of course, they had a little help from building services consultants

There's an endless supply of reasons for poor performance in schools, but Manchester City Council has set about eliminating at least one of these. Aware that many of its classrooms were too stuffy and pupils' academic performances were suffering as a consequence, classroom air quality was high on the council's agenda when, in 2004, it set the brief for 16 new schools to be constructed. These were to be built under the first wave of its £180m Building Schools for the Future programme.

The task for Whitbybird, the services consultants to contractor Balfour Beatty for the project, was to find a solution to the air quality problem - a challenge made more difficult by impending revisions to the Building Regulations, which were to apply to schools for the first time.

"The concentration of CO2 in the room is the best indicator of air quality," observes Andrew Peters, a director of Whitbybird and the lead services engineer on the project. "The higher the concentration, the more stuffy the room and the harder it is for pupils to concentrate. Teachers can sense uncomfortable temperatures, but it's difficult to tell when CO2 increases."

Existing guidance in the form of Building Bulletin 87: Guidelines for Environmental Design of Schools failed to give a figure for maximum acceptable concentration of CO2 in a classroom. Although the document recommends a minimum fresh air rate of 3 l/s per person and states classrooms "shall be capable of being ventilated at a maximum rate of 8 l/s per person," Peters says it "fails to give a limiting value for CO2 levels and therefore a limit to poor air quality".

The council was fortunate in its quest for improved air quality because the government had just published an outline document giving new design guidance on ventilation for schools. The draft of Building Bulletin 101: Ventilation for School Buildings recommended a maximum concentration of CO2 of 1500 ppm, calculated as an average over the normal teaching day including lunch breaks. This was the figure Manchester City Council adopted. "The council's brief imposed a limit on CO2 concentration ahead of the introduction of the DfES's design guide BB101," says Peters. The council also asked the designers to consider how the future use of IT might affect summer peak temperatures.

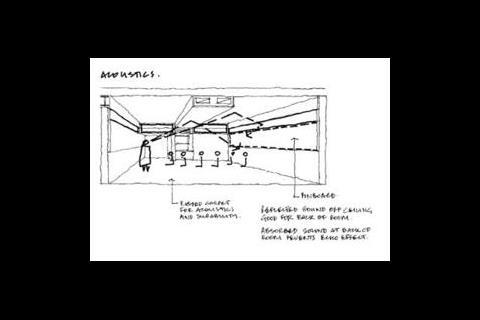

The task now was to work out the best and most cost-effective way of achieving this target. "We had to satisfy the design guidance contained in BB87, the bespoke requirements of Manchester City Council, the budget constraints imposed by the DfES, the energy related requirements intended to bring the design of schools in line with the [then] forthcoming changes to Part L, the often conflicting BB93, which deals with noise levels in classrooms, and proposed new design guidance contained in BB101," explains Peters.

An open and shut case?

Existing guidance in the form of BB87 favoured natural ventilation by opening windows on the basis of capital cost and energy use. The first task for Whitbybird was to find out if the concentration of CO2 could be maintained at the levels recommended in the new document by opening the windows. "The main source of CO2 in a classroom is the occupants themselves, so the overriding factor in determining the concentration level is the flow of external fresh air into the room," says Peters.

Based on each child generating CO2 at a rate of 20 l/hr, the designers calculated that a fresh air rate of 6.2-9.9 l/s was required for each occupant to keep CO2 levels within the target required. Case studies revealed that the room's high occupancy, equipment gains and solar radiation could lead to overheating in summer. "Ventilation rates needed to cool a room are far greater than fresh air rates," explains Peters. The problem is compounded by variable air pressure and buoyancy, which will affect rate of air movement. It's likely the classroom windows would be open and sufficient fresh air would keep CO2 concentrations within acceptable limits.

However, in winter it was a different story. Even if the designers neglected the problem of cold draughts caused by open windows, the proposed energy targets in the new Building Regulations would ensure that warmed air could not be allowed to simply drift out of the window, to be replaced by cold outside air. "Because the occupant density is so high in a classroom (less than 2 m2/person), without heat recovery on the ventilation, the building would exceed the maximum permitted carbon emissions of 5 kg/m2/year," explains Peters.

Mechanical ventilation

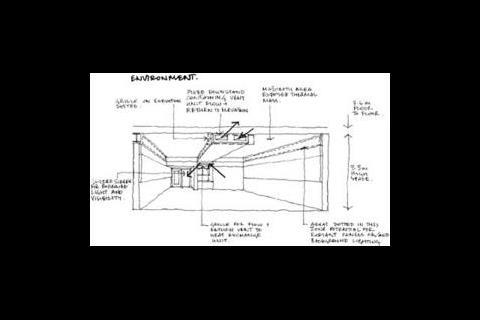

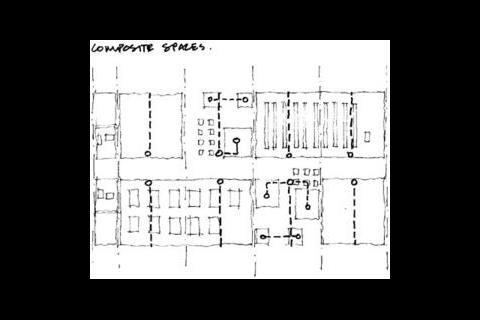

It was clear to the team that some form of controlled mechanical ventilation would provide the best solution. Whitbybird considered both central and local ventilation systems and concluded that local ventilation units mounted within a ceiling void was the best option.

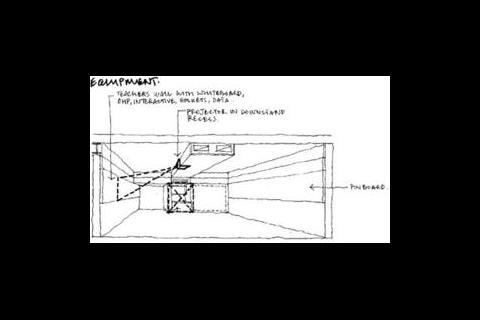

The consultant developed a solution around a classroom-based ventilation system with heat recovery and summertime extract fan boost to increase ventilation rates in warm weather. The unit will have a heat recovery heat exchanger, a heater battery (sized to meet total heat load) and supply and extract fans. To keep costs down, prefabricated units including lighting, fire alarms and even data outlets were developed.

The advantage of this solution is that it allows room-by-room zoning, which would save energy by allowing the units in unoccupied rooms to be turned off. This solution would also allow the phased refurbishment of schools. And, because the units incorporate a heat recovery system, they are also energy efficient. Peters claims the module can save up to 6 kW of energy per classroom, with the added bonus that a smaller boiler is needed than if radiators were used.

Would it work? Manchester City Council was keen to carry out a long-term trial in a live environment to ensure this was the optimum solution and provided Whitbybird with an ideal laboratory. The council selected two adjacent first floor classrooms at Chorlton High School, a recently built BB87-compliant block. The rooms both suffered from poor air quality and high summertime temperatures. One classroom was kept as the control, with the teacher free to open or close the windows. The other had the prototype classroom-based ventilation system installed and the windows remained closed. The results are shown, right, in the box Testing the mechanically ventilated solution.

Testing, with a unit built by Balfour Kilkpatrick,began in September 2005 and will run for over a year. It's early days, but initial results appear to confirm that the problem of poor air quality has been solved by introducing mechanical ventilation. The results are important because BB101 came into effect in April 2006 and so the classroom CO2 concentration in all new schools need to be below the 1500 figure.

What's more, Whitbybird claim the solution actually works out cheaper. Peters says further work on both capital and lifecycle costs are needed as a comparison is difficult because many savings relate to the building fabric - for example the ability to use cheaper un-openable windows - but workshop results indicate that the mechanical ventilation solution has a lower capital cost than the natural ventilation alternative. Table 1, on page 56, gives approximate running costs for the scheme.

The system will be rolled out in Manchester schools over the next few years, with the first two schools starting on site this summer.

Testing the mechanically ventilated solution

When testing began on 5 September 2005, one of the key initial findings was the high concentration of CO² in the external atmosphere around the school. Whitbybird’s instruments showed it to be as high as 445 ppm – 15% higher than UKCIP02 and CIBSE published figures of around 380ppm, according to Peters. This is probably due to the school’s city centre location and means that the fresh air for CO² dilution is already at a higher concentration than that used by the DfES to determine fresh air rates – so a ventilation rate higher than 8 l/s would be required to maintain the DfES threshold.

Graph 1 shows the CO² concentration for both classrooms for a typical day in October. The graph shows the record for one of the four days when the concentration of CO2 within the naturally ventilated classroom peaked above the 2000 ppm level. At its peak, the sensors measured 2032 ppm, whereas peak concentration in the mechanically ventilated room was 1475 ppm. “This equates to a 27% reduction in the peak CO2 level,” says Peters. This is all the more surprising since October’s temperatures were well above average across the UK which, according to Peters, was “ideal for natural ventilation”.

In January, CO² concentration levels were higher in the naturally ventilated classroom – probably as a result of the windows being closed in inclement weather. Graph 2 shows CO² concentrations in the naturally ventilated room flattening at peak 2000 ppm from midday through to 3.30pm. This is because the CO² sensor could not record concentrations above 2000 ppm so the peak concentration was probably much higher.

Downloads

Graph 1: CO² levels in both test classrooms on a typical October day

Other, Size 0 kbGraph 2: CO² levels in both test classrooms on a typical January day

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet