The Shard may have attracted all the attention in the last year but its little sister, The Place, represents just as accomplished a technical feat

In some respects, the London Bridge Quarter development is like the story of two competing sisters. The first-born - the Shard - is tall, glamorous and attention grabbing. The younger sibling - The Place - is plain and overshadowed by its big sister. It has had to compensate by being much more accomplished than meets the eye. If the Shard is a supermodel then The Place is a talented gymnast.

Keeping The Place low profile was a deliberate policy on the part of developer Sellar. “We had to ensure the building didn’t detract from the Shard and that it was a unified part of London Bridge Quarter,” explains Flan McNamara, Sellar’s project managing director. He adds that, unlike the Shard, the 14-storey Place is aimed at single corporate occupiers. “It was important to get the right sort of floorplate for the market; big corporate occupiers demand floorplates of 20,000-30,000ft2.”

Flexibility

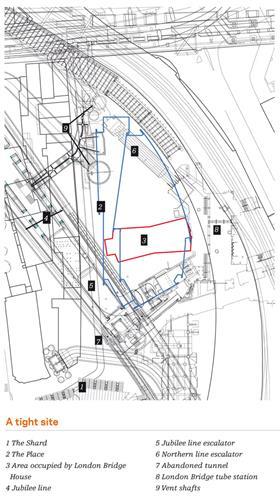

The trick has been to squeeze these large floorplates into the much smaller space occupied by The Place’s predecessor London Bridge House. This building was boxed in on all sides by a spider’s web of underground infrastructure, which limited the extent of the foundations. This included the Jubilee line tunnels and platform access escalator on the south-eastern corner of the site; the Northern line escalator to the north-east; and London Bridge underground station to the north; and the south and west side of the site is delineated by three underground ventilation shafts.

Creating those big floorplates in this space called for some clever structural gymnastics. The structural footprint of The Place equates to the space occupied by London Bridge House but is just 45% of the area occupied by the new building - The Place occupies 55% more space by cantilevering over the underground infrastructure. This called for some clever structural design with a compressed programme adding to the challenge. “In many respects this is a much more complex building to put together than the Shard,” says Mace’s Gordon Gray, the operations director responsible for delivering the £137m construction contract.

The space-constrained nature of this project meant building as close as possible to the underground infrastructure. London Underground requires a 3m exclusion zone around its assets, which would have made this job impossible to deliver. For example, two piles straddle the Northern line escalator and a pile supporting one end of the building had to be located 1.5m from the Jubilee line. “The main thing was to design a system that would allow existing activity to continue and avoid any movement of the existing assets,” explains Kamran Moazami, head of engineering for structure at WSP. So, 3D finite element analysis was used to analyse potential ground movement and convince London Underground that it was safe to work within their usual exclusion zone.

Timing

Another complicating factor was the presence of Roman artefacts, which meant excavations had to be painstakingly raked over by an archaeology team. The unpredictable nature of archaeological excavation posed a big risk to the programme. This had to be minimised as much as possible, so the team responded by the drastic measure of reducing the depth of the basements by one level. “We looked at this purely from the risk point of view,” explains McNamara. “The deeper basement would have meant a longer archaeology period and time lost in the ground is never made up.” But how did Sellar stomach losing a whole basement from their project?

The answer was BIM - it was used to package the plant rooms more efficiently, saving one basement level’s worth of space and construction cost (see “Modelling The Place” below).

Because the archaeological work was going to take so long the team had to find a way of getting on with the job before it was finished. Top-down construction was the answer as this enabled work to progress above ground while the basements were being dug. The area occupied by the piles was excavated by the archaeologists and backfilled, ready for piling. The secant wall used to retain the basement perimeter was piled and the plunge columns used to support the core, and other columns were installed. There was so little room on the south-eastern side of the site that a 2.4m-diameter pile was needed to support this corner of the building. Just 1.5m from the Jubilee line, this was formed from 280m3 of concrete, which was poured continuously over 21 hours. Piles close to the underground infrastructure were sleeved to minimise ground movement.

The twin cores were “jumpstarted” on this job, a technique pioneered on the Shard. This enables a core to be built above ground before the core walls are cast underground. The core is supported on the plunge columns and the basements are excavated, then the core walls are cast around the plunge columns. This ensured that the archaeological work would not impact on the superstructure construction.

Work on the Shard core stopped at 21 storeys due to the risk of the plunge columns buckling without the support of the concrete walls. But as The Place is only 14 storeys high, this wasn’t a risk so the cores could be finished before the basements. “At one stage we had demolition, archaeology, piling and the core all going on in a very small footprint because the programme was so demanding,” says Gray. The first core was finished in September 2011, nearly a year before the basement slab was cast in June 2012. “We cast the basement slab and put the last bit of steel at the top of the building within a weekend of each other,” says Gray. “This verified

why we did this job using top down construction. It allowed the archaeology to be done without compromising the job.”

Strength

Squeezing a quart of a building into a pint pot of ground meant the pressure was on the steel frame. “This was one of the most complicated parts of the programme,” says Jack Adams, WSP’s technical director. The frame had to cantilever outward from the area of the building founded on solid ground by up to 12m. The frame is cantilevered round most of the building perimeter at third-storey level. Rather than opting for a space-hungry two storey high transfer structure, WSP has come up with a corbel arrangement to transfer the loads more efficiently. Raking columns extend from cores to perimeter. These angled columns extend from level three to levels 11 and 12 and are tied back to the cores with tie beams. This creates a strong, triangulated structure.

The area of structure below the raking columns is suspended off these. This meant temporary works were needed to support the lower parts of the frame while the corbel arrangement was erected. Once again, the constrained nature of the site put pressure on the team. The Place cantilevers over the bus station next to thebuilding, so the temporary works had to be located in the bus station. In addition, they had to be down in time for the Olympics.

The meant taking the frame up to four storeys on the north-west side of the building before work started on the other side. Because the frame is not supported at ground level and was not counterbalanced by the frame on the other side, it placed asymmetrical loads on the cores, pulling these over towards the bus station on the north-western side.

What has made this job particularly unusual is that the cores will be permanently under asymmetrical load when the building is finished. This is because the building and associated cantilevers are asymmetrical, so the building pulls over to the east. The cores feature more reinforcement and have thicker walls to increase stiffness. Despite this, the weight of the building will cause the cores to deflect towards the east. The cores have been built with a “preset”, a lean towards the west. The idea is that the cores will be gradually pulled vertical as the building is finished.

As the frame was built up, the loadings on the cores and individual steel members kept changing. “We had to second-guess the movement of the building,” says Gray. Engineer Robert Bird & Partners had the job of predicting this movement and the impact on construction. Movement was carefully predicted, with presets built into the frame so it would end up in the correct place. “The building has been surveyed to within an inch of its life,” comments Gray. Sellar also employed engineers to check the building, as a safety net. The frame is now finished without any problems. “Thank God the modelling proved to be very accurate,” says McNamara.

A final flourish

Getting the cladding right while the frame was moving was another challenge. “The cladding is built to very high tolerances and you will see any distortion if it isn’t perfect,” says Gray, adding that the engineers originally wanted to wait until the building was finished before starting the cladding. “This is a commercial project and we couldn’t wait that long,” he says. The solution was to wait until the frame was well advanced before starting the cladding.

The cladding has been installed with a preset so it will move into the right position once the building is finished. Gray adds that there are two columns on the perimeter of the building on the south side and three on the north. As part of the frame perimeter is on a combination of ground-bearing and core-supported columns, it has settled differentially, which had to be accounted for in the predictive modelling.

With the frame completed, the cladding is going on quickly and the services are advancing inside. It is due to be finished by June, which is impressive given the difficult nature of this project and the 131-week programme. The question now is: can Sellar find a corporate tenant to occupy it and make the achievement worthwhile?

MODELLING THE PLACE

Computer modelling has played a central role in enabling this complex project. Sophisticated computer analysis enabled WSP to demonstrate to London Underground that it was safe to build within its usual 3m exclusion zone. The area affected by ground movement overlaps the zone affected the Shard and Borough Viaduct construction sites. The 3D finite element analysis was used to assess these risks.

“The biggest movement we identified was 4mm to 5mm on some of the assets,” explains Jack Adams, WSP’s technical director. Due to this reassurance London Underground was prepared to allow Mace to work within 1.5m of the sensitive Northern line escalators and work was constantly monitored for movement.

The asymmetrical nature of the loads in The Place called for non-linear analysis to understand the direction and power of the forces in the building and respond with an efficient structural design. Non-linear analysis was pioneered immediately after the World Trade Center attack in 2001 and was used to understand the disproportionate collapse of structures. This helped engineers design more resilient buildings and is now useful for designing complex structures such as The Place.

Sellar wanted to use BIM for the building design to help streamline its operation. WSP was responsible for the modelling and has worked with FM software specialist Zutec to enable the BIM to be imported into their tool. BIM has also made the design and delivery of this project more efficient, saving 10% on build costs.

Originally, there were two levels of basement plant rooms but one was taken out to save time and reduce programme risk. This was done by modelling the plant and packaging it more efficiently. McNamara says that BIM was the key to this process. “We wouldn’t have compromised on this as we have to maintain the plant,” he says. “Without BIM we wouldn’t have had the confidence to do it.”

BIM was also useful when Mace found an old metal shaft in the way of the secant wall. This turned out to be a forgotten entrance to the old City & South London underground line. BIM enabled a rapid redesign of the secant wall so it could be taken around the shaft. Using BIM also meant the position of openings for services could be predicted. Sellar had an agreement with Mace that no holes over 150mm in diameter would be cut in the structure after the concrete had been cast. Mace’s Gordon Gray found the BIM beneficial too. “You don’t have to rework and you don’t have to cut holes,” he says. “There are still clashes but nothing like the drama we usually get.”

PROJECT TEAM

developer Sellar Property Group

design architect Renzo Piano Building Workshop

executive architect Adamson Associates

project manager Turner & Townsend

structure and services engineer WSP

construction engineer Robert Bird Group

facade consultant Aecom

cost consultant Davis Langdon

main contractor Mace

demolition and enabling works Keltbray

concrete Byrne Bros

steelwork Severfield-Rowen

vertical transport Kone

drylining BDL

external works and hard landscaping Grants of Shoreditch

1 Readers' comment