Right from the start, Foster + Partners’ Willis building was blown off course by legal problems and higher than expected winds. But much worse was to follow ... Thomas Lane found out how the team behind the City skyscraper fought back

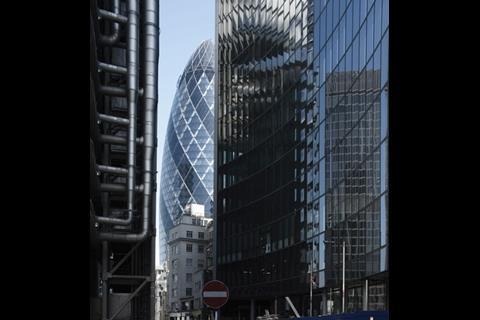

Two buildings epitomise the different styles of Britain’s two most famous contemporary architects. And conveniently for critics, they face each other across a narrow urban street. The first is Richard Rogers Partnership’s Lloyd’s building, which pretty much sums up its designer’s flamboyant and expressive approach, and which set the tone for an era. These days, at street level it resembles a chemical production plant, thanks to the accumulation of London dirt – which only serves to emphasise the stylistic differences of its new neighbour over the road. This is 51 Lime Street, also known as the Willis building, as it is to be occupied by the insurance broker of that name. This urbane, elegant Foster + Partners design is the first of a new wave of London offices, and can be fully appreciated now that its sleek cladding has been completed.

The average City worker wandering down Lime Street will have no idea how difficult it has been to create this architectural dialectic. The principal physical problem was the wind, as it stopped tower cranes from operating. “The weather has played far more of a part than we had planned for,” says Andrew Highton, director of developer Stanhope. “On average we’ve been unable to work for 40% to 50% of the time during the winter; we had calculated it would have been 20%. To put it bluntly, for every day you lose, it’s another day on the programme.”

But this pales into insignificance compared with the economic problem the project team faced with the cladding package. The contract was placed with the Swiss firm Schmidlin, which went bust at a critical stage of the works. “It was the week they were meant to start fabricating the cladding panels,” says Nick Moore, the operations director for Mace, the construction manager on the job. “I couldn’t believe it; it left us in a very awkward position. The big worry was a lot of other jobs were being affected at the same time so we thought we could be delayed by up to a year.” But Highton, Moore and the rest of the team managed to complete it just three months later than originally planned. How did they pull it off?

Things started off reasonably well. Enabling works started at the beginning of 2005, planning was granted in March and piling started on 4 April. Problems with a multitude of party wall agreements meant that Mace didn’t have a clear site and had to contend with demolition taking place on the west end of the site while it was knocking in piles at the east, a situation that Moore describes as “a setback”. Once the site was cleared, the double-height basement was constructed and work started on the concrete cores.

Windy conditions during the first winter meant the all-important cranes were not operating as often as expected. Something had to be done to prevent the programme running away. “We worked with the steel and concrete guys to see how we could improve their productivity,” says Highton. “With a high-rise you have the opportunity to look at each floor and see how you can improve things as you go up the building.”

One opportunity was reducing the time it took to cast the concrete cores. This was being done by Laing O’Rourke using the jumpforming technique. This was favoured by Moore as it enables the core walls and landings to be cast at the same time, and is very accurate. Moore says the cores were built to an accuracy of ±15mm over the 125m height of the building. But it was taking between six and seven days to cast each floor. Laing O’Rourke worked with steel contractor William Hare to allow the steel connections in the cores for the steel frame to be put in at the same time. This cut the time to cast each storey down to four days. “We managed to take the concrete back from being the critical element,” says Highton.

The team then focused on cutting down on the time needed to build the steel frame. One innovation proposed by William Hare was the “Lancashire column”. This is a two-storey metal tube, and it was used to encase the steel columns at the perimeter of the building. The tube is craned into position and filled with concrete. “It saves having to fireboard the columns and gives Fosters a nice round column, which is what it wanted,” says Moore. Another timesaver was the use of precut metal decking for the composite concrete floors of the building. “It offers you the advantage of speed; equally, you do not have people grinding decking with angle grinders 100m up in the air with the noise issue and sparks flying off the edge of the building,” says Highton. “We were in a situation where we didn’t have to hound the steel decking people, which is unusual.”

Time was also clawed back by the simple expedient of working weekends, and longer days during the summer months. But safety was not compromised, and some work methods were introduced even though they slowed things down. Highton points to the steel erection technique that was used for the first time on this project. Cherrypickers are commonly used on low-rise buildings to bolt the steel in place but never on high rises. On these projects, ladders are used, and workers shimmy along beams to bolt steelwork together. Unsurprisingly, this practice is frowned upon by the Health and Safety Executive. At the Willis building, special tracks were used so the cherrypickers could run along beams and over the ribbed decking – a technique that turned out to be slower than more traditional methods. “It was slower because of the geometry of the steel but it will be faster in the future once the guys get used to it,” says Highton.

Highton says the timesaving measures would have put the project back on track for completion as planned. But nobody could foresee the demise of Schmidlin in February 2006. This put Stanhope in an awkward position as it was actually in contract with Schmidlin UK, which was still trading. “You have to talk to the company you are in contract with and you can serve them notices but at the end of the day there is nothing you can do about it,” says Highton. He says the factory in Switzerland contained crates and crates of materials for the project but nothing had been made. Others were luckier; for example, negotiations secured the release of completed cladding panels for the nearby Aldermanbury Square project.

The team explored two options. The first was to stick with Schmidlin and see what happened; the second was to go to another cladding contractor, namely Gartner, who had been involved in discussions at the beginning of the project. “Whatever we did it was a gamble,” says Highton. If we had gone with Gartner, we would have had to redesign the facade to suit their fabrication methods, which would have taken months and there was no guarantee they could source the materials.” While the team were deliberating, things moved on – TSK Troester, a global group specialising mainly in automotive parts, bought Schmidlin to form Schmidlin TSK.

The team decided to sign a contract with the new UK arm, Mero Schmidlin. “It was pretty much a gut feeling; the question was, could we work with these people?” says Moore. Helpfully, Schmidlin UK went into voluntarily bankruptcy. “The contract was history so we could then sign a new one with Mero Schmidlin,” says Highton. It was signed in June and covered the supply, fabrication and installation of the cladding system.

Mero Schmidlin was formed from existing company Mero by managing director David Barrow, who had worked for Schmidlin 10 years ago. “It’s been an extremely challenging process,” he says. “One of close co-operation and fast decision making.” Barrow had to quickly recruit a project management team, then work started on fabrication. “We had a very demanding programme to minimise the delay our clients were suffering,” he says. The Swiss factory worked extra shifts.

In the meantime, Mace had to press on without the benefit of a weathertight envelope, as by now the steel structure was racing towards completion. “We said we can either wait for the cladding and put the programme back six months or press ahead,” says Moore. Undeterred, work started on the M&E installation and internal plasterboard linings. This progressed well at the lower levels of the building but had to stop at higher levels. “Once we got above the Lloyd’s roofline we were really exposed,” says Moore. But it was vital to get the plant up onto the roof and the power on to keep on track.

The answer to the plant room dilemma was a product called Envirowrap, a plastic sheeting system used to encapsulate buildings. This was used to wrap the top two floors of the tower to enable the installation and commissioning of the power supply. Moore says Envirowrap was extremely effective as it stood up to a particularly fierce storm on 18 January this year. “We didn’t have any water in during that storm so it was the right decision,” he says.

In the meantime Mero Schmidlin was busy installing the cladding lower down, having started installing the first cladding panels in August 2006. It even developed a special piece of equipment to install the cladding panels so as to reduce the reliance on the precious tower cranes. Reaching this stage was an enormous relief to Moore. “Psychologically, having the cladding on was a big lift,” he says. “It was the first time in a site meeting where we didn’t have tea or coffee, we had champagne.” On 28 March, the last panel was positioned. “The product is as good as anything that would have been delivered by Schmidlin, and they’ve delivered on the day they said they would,” beams Highton.

The team is currently handing over the building to StructureTone which is doing a £40m fit-out for Willis Group. In 2008 Willis will move in and start taking full advantage of a key reason for choosing this state-of-the-art building next to Lloyd’s. Apparently the insurance industry still prefers bundles of paper to electronic communications. This means they can just nip over the road to the Lloyd’s building. From the sublime to the ridiculous perhaps?

Matching the building with the tenant

51 Lime Street consists of two buildings, a 10-storey block facing Billiter Street and a 29-storey tower with three distinctive steps at the 16th and 23rd floors facing Lime Street, which creates two roof terraces for Willis’ employees. The top five floors of the tower are relatively small and are used for plant.

The development is a collaboration between British Land, the owner of the site, and Stanhope the developer.

Once planning permission was granted in 2002 for an office development, British Land set about finding an occupier and eventually signed up the Willis Group.

Rob Harrison of Foster + Partners says: “It was exactly where they wanted to be: right in the middle of the insurance area next to the broking market.

“Everything was right except it didn’t need that much area” The challenge was to make the building smaller without changing the design too much.

“The easy thing to do would have been to take floors off, but that would have spoiled its elegance,” says Harrison. The solution was to make the tower slimmer by cutting into its triangular shaped rear to create a curve.

Also the two buildings were going to be joined together at the lower levels; instead they are separate, with the space at ground level turned into a public thoroughfare, as it was in the 19th century.

How the cladding helped energy efficiency

The cladding not only gives the Willis Building its sleek appearance but is also a sign of things to come. Although the design complies with the 2002 version of Part L of the Building Regulations, the intention was always to exceed this. It has been checked against the latest, 2006 Part L and is compliant with that, too. The cladding is a key part in the building’s performance.

Reducing the glazed area is part of the strategy. The north and south elevations have a sawtooth profile, with one side of the tooth solid, the other glazed. Not only does this give the building its striking vertical emphasis on these elevations but it also helps shade it. “We decided to go for solid areas because of concerns over how you maintain and clean louvres more than 100m above street level,” says Highton.

The east and west elevations are fully glazed but double skinned with a ventilated cavity to reduce heat gain. A blind is incorporated within the 300mm deep cavity.

Elsewhere gas boilers are used for heating with local heat provided by fan-coil units with electric reheaters. This demonstrates that this heating method can get through 2006 Part L if an efficient facade is used.

Full lighting controls are used throughout the building, which also helps with energy efficiency.

Project team

Building owner British Land Company

Tenant Willis Group

Developer Stanhope

Architect Foster + Partners

Structural engineer Whitbybird

Services engineer Roger Preston & Partners

Cost consultant Davis Langdon

Construction manager Mace

Enabling Works McGee

Piling Expanded

Concrete Laing O’Rourke

Structural steelwork William Hare

Curtain walling Mero (UK) & Schmidlin - TSK

Site surveying Site Engineering Surveys

Logistics Wilson James

Roof cladding Roofdec

Louvre roof CMF

Roofing Prater

Brickwork Irvine Whitlock

Drylining Fireclad

General building Clipfine

Insulation Abbey Thermal

Toilets Swift Horsman

Core and lobby fit-out Mivan

Hard floor and wall finishes Grants of Shoreditch

Glazed doorsets Pollard Hansen

Metal stairs Glazzard

Metal doors Jewers Doors

Decorations S Lucas

Sprinklers Tyco Fire & Integrated Solutions

Mechanical services Axima Building Services

Ductwork Hotchkiss BMS Celsius Controls

Electrical installation Phoenix

Fire alarms Protec

Verification engineering Commtech

Commissioning Watson & Sole

Lifts Otis

Softlandscaping Hasmead

Roof derrick Xena Systems

Hoists Hewden Stuart scaffolding Benchmark

Sccommodation steelwork Allister Welding

Tower cranes Laing O’Rourke

Downloads

How the Willis building fits in

Other, Size 0 kb

No comments yet