The virtues of infrared control are simplified and more economic installation, greater flexibility for later modification, avoidance of problems associated with routing wiring to the point of control, and reusable components.

It can also be used in a wide range of buildings, however it is particularly useful in buildings which have a high rate of churn as well as those where there are problems with the use of conventional wiring.

The following two case studies illustrate the issues involved in applying this technology.

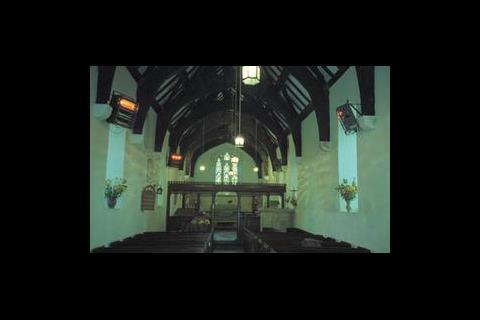

St Mary's church, Llanfair

St Mary's, a 15th Century Anglican church in North Wales, has recently replaced its heating system with wall-mounted, three-tube, quartz halogen heaters. The drawback with the system was that when the heating was set to an adequate level to make the church comfortable at the start of a service, it would often be uncomfortably hot by the end.

An economical and user friendly control system was needed and rather than adopting the conventional solution of installing power switches wired to the heaters it was decided to opt for a cordless control system.

The installation

Each heater was fitted with an infrared receivers/actuator module to switch two of the three lamps, the third being controlled by a central master switch. An associated cordless switch was mounted on the end of the pew opposite the heater, a position chosen to ensure line of sight between transmitters and receivers.

The receivers are mains powered through the heaters. The associated switches have an infrared transmitter and are battery powered from two AA batteries. In normal operation, the shelf-life of batteries would be reached before they were exhausted.

The extra costs of the infrared system included the four double infrared switches and four receiver/actuator modules, which cost £220. There were unquantified savings in the cost of conventional cable and conduit, and in reduced labour, which was estimated at 90%. The total cost saving was several thousand pounds.

The receivers and transmitters were programmed with a unique identification code, although the system can allow multiple point control of a single heater if required. The two switches on each switch module result in different data being transmitted to the receiver module, which is configured to switch two different lamps in response to the different signals.

According to the electrical contractor, the programming of the devices took 15 minutes to learn, one minute to execute and required no special skills or tools.

Post-installation issues

In the 12 months since installation the feedback has generally been good. The system requires no maintenance other than the regular replacement of batteries.

Like so many innovations, the biggest barrier to the use of infrared control systems is the inertia of current practice. The possibility of using infrared control for lighting and other systems is generally not even considered.

Some people will perceive the initial cost of the equipment to be a barrier. A receiver module and a switch module together come to about £55, but this cost would often be outweighed by the costs of a conventional wiring installation, especially if conduit or trunking is required.

The solution to this problem is to encourage people to think in a more rational way about costs. Overall cost is what matters, not capital cost, but life-cycle costs are an even better way of assessing the real cost-effectiveness of a system.

PricewaterhouseCoopers

Financial services company PricewaterhouseCoopers (PwC) has recently refurbished its Bristol offices. These are a mix of open-plan and cellular spaces which have been reconfigured with partitioning to create new office spaces. Some new lighting has been installed, while the rest has been upgraded or had new controls fitted.

Because of the frequent need for reconfiguration and the consequent demand for flexibility, the previous lighting installation had used an earlier infrared control system based on hand-held remote controls, and a receiver that controlled the lighting through a two-wire bus cable. However this system was no longer supported, so it was not possible to extend or modify it. In addition, there was some negative user feedback concerning the hand-held controls, which could be mislaid or taken away.

System description

Each of the refurbished rooms has had its lighting control system replaced by an infrared system. Double infrared switches are mounted on the walls and partitions and the lighting control units are mounted above the ceiling tiles, to switch a circuit of luminaires.

In this system the infrared sensor for the luminaire circuit is connected to the body of the receiver by a wire. The sensors are inconspicuous devices about 10 mm across, with a clear plastic cover and located in holes in the ceiling tiles.

The infrared control system had moderate hardware costs and low installation costs. The system is easy to relocate as is the addition of switches, making it particularly suitable for an installation with a high churn rate. It was also easy to install, configure and extend.

Post-installation issues

The light switches operate conventionally, making it unnecessary for users to become acquainted with an unfamiliar interface. The fact that the switches are firmly mounted on walls (or even glass panels) makes them easy to find but difficult to lose, unlike remote control devices.

In the event of a refurbishment where the layout of spaces is changed, the switches can be relocated to wherever it is convenient. If it is necessary to control the lighting in a different way (for example if a large open- plan space is converted to cellular offices) the switches and lighting controllers may be reused to control a different subset of the lighting and extra switches and controllers can be added.

Over relatively short distances, line of sight is not necessary, making it possible to use the system where direct line of sight to the switch may be obstructed, for example by people.

Barriers to the use of this type of infrared control system seem few. The capital cost may put off some clients, particularly in very economical new-build projects, although a more careful assessment of total costs may make this argument invalid.

The need to replace batteries after several years is a minor disadvantage compared with conventional light switches and dimmers. The risk of forgetting to replace the batteries and misleading end users into thinking the lighting was not working could be reduced considerably by having a strict maintenance schedule, where all the batteries were replaced as appropriate, or by the addition of a 'battery low' indicator to the switches.

Summary

The two case studies show that there are clear process and economic benefits from the use of infrared control technologies in very different scenarios. The reduction in installation costs can be considerable, and there may be substantial economic benefits in buildings that are subject to high levels of churn.

The technology is new and there have been some initial technical problems, but manufacturer's have responded positively to feedback and improved products.

Source

Building Sustainable Design

Postscript

The two case studies were undertaken in the course of the BRE research project 'Overcoming the barriers to standardised wiring systems', funded by the DETR.