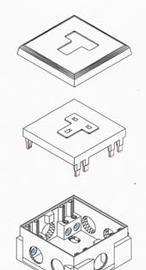

The system comprises of three basic parts, an accessory box that is installed with the conventional conduit system, a plug-in accessory and a temporary cover plate. The accessory box provides the permanent termination of the wiring with plug-in facilities to take the accessory, which could be anything from a socket outlet to a light switch. The design of the accessory box also allows the accessories to installed in geometric patterns.

A temporary cover plate replaces the accessory during construction and maintenance to protect the interior of the box and allows finishes to be applied to the building prior to plugging in the accessory, thereby avoiding accidental damage and over painting. The plug in nature means that final connection is both fast and doesn't require a qualified electrician, and as the accessory isn't hard wired it can be removed from the accessory box while the circuit is still live. This allows faster maintenance with 'hot' replacement of accessories creating less downtime which is particularly important for critical situations such as computer installations where it is operationally difficult to switch off a circuit to replace an accessory.

Multi-voltage systems

In the UK there are areas within a building that are often required to operate on 240 V single phase and 415 V three phase, such as commercial kitchens, laboratories or workshops. In a commercial kitchen, for example, equipment may need to be moved to suit changing working demands. By wiring the installation with three phase radial circuits throughout, it is possible to swap a single-phase outlet for a three-phase outlet and visa versa. Care, however, is needed to ensure cable sizes are chosen at design stage to deal with this application.

In other countries, such as Saudi Arabia, domestic premises operate on 220 V three phase and have appliances at 220 V (two phase and no neutral) and 127 V (single phase and neutral). Inevitably some appliances are only available in one voltage and Murphy's Law says the local outlet probably doesn't have that voltage. Wiring the installation with three wire and earth radial circuits instead of two wire and earth, means it is possible to install either a single phase or two phase outlet anywhere in the installation. This improvement comes at the cost of one extra cable installed on each circuit.

Interchange of accessory types is also possible. Building occupiers may want outlets that are equipment specific. An American company operating in the UK may import all its technical equipment from the USA and, although able to operate on 240V 50 Hz, come with American plugs. The rest of the office equipment may be obtained locally and have British pattern plugs. American pattern outlets can be installed where required and British pattern elsewhere. Moving them around if equipment locations change would be straightforward, unplugging an accessory and plugging in another, while the circuit (extending into other areas) is live.

Two areas where the application of 'hot' replacements could be particularly beneficial are speculative development buildings and critical care facilities. Typically, speculative office developments do not have tenants at the time of completion. The preferred type of accessory by the eventual occupants is therefore often not known. By incorporating the new system, the whole wiring installation is completely terminated and tested during the construction. The tenants preferred accessory finish and type can be plugged in prior to occupation. A proven installation with no waste.

There are potential improvements for critical care installations. Because the accessory is plugged in and not hard wired, it can be removed from the accessory box while the circuit is still live. Typically, on a bed head unit in a critical care hospital ward with several outlets connected to the same circuit it would no longer be necessary to switch off the circuit to replace a faulty accessory. Equipment can simply be plugged into another outlet while the faulty accessory is unplugged and replaced.

Effect on costs

The conventional system, because it is only completed fairly late in the project, means that it is not possible to use it during the contract even if the contractor wishes to. The alternative plug-in system allows the contractor to connect and use the safer permanent wiring systems as the temporary site distribution and verifying its integrity prior to handover. It also means the contractor can minimise the time his temporary supply equipment is on site and reduce the capital locked up in it.

Properly applied on cradle to grave principles, the new system should be less costly than the traditional system. Plug-in accessories would cost more to purchase compared to traditional devices as they have more components, however the cost benefits are there if all the parties in the building and facility management industry properly reflect the savings that are inherent in the new system. This requires engineers to apply the benefits to their designs and specifications, clients to allow the contractor to use the permanent wiring, contractors to reflect the savings on their prelim costs and allow for the effect on their contract programmes. Clients and developers also need to reflect the benefits of selecting the system including the additional flexibility-in-use for building occupiers and increased economy in maintenance.

Source

Building Sustainable Design

Postscript

For more information contact Peter deBoeck IEng. ACIBSE, MIIE at peter@deboeck.co.uk

No comments yet