If you’ve ever thought of giving it all up and moving to a villa in southern Europe, you probably envisaged swapping those deadly winter heating bills for similarly dire air-conditioning bills.

When the results came back for the Alma Verde Village and Spa in the Algarve, south-west Portugal, they were, says Phil Todd, better than all the preliminary calculations had predicted. They also provided the answers to a number of unknowns.

The results were from the final stages of the Coolhouse initiative, a project part-funded by the European Union’s energy research directorate, looking into low tech cooling strategies that make use of the ground’s thermal mass. “The objective of Coolhouse, which included similar schemes in France and Italy, was to find ways of reducing the use of conventional domestic air-conditioning in southern Europe,” says Todd, an associate with Hurley Palmer Flatt, M&E consultant on the scheme. The ultimate aim is to find ways of reducing the 90 million tonnes of CO2 emissions domestic air-conditioning systems are estimated to account for across southern Europe every year.

“At Alma Verde the intention was to achieve zero or low-energy comfort cooling of single-storey houses where air-conditioning might otherwise be installed,” says Todd. Situated in an area of Portugal that receives more than 3000 hours of sunshine a year, the development includes 122 villas, 32 town houses and several groups of low-level apartments.

Initial studies on the use of ground tubes for the scheme were carried out by ECD Architects, whose investigations into the subsoil characteristics indicated temperatures at a depth of 2 m to be about +/-2°C of the annual average air temperature. Armed with this data, ECD calculated that about 2.5 kW of cooling could be provided to each dwelling by delivering the ventilation air through a pair of 25 m long ground tubes separated by 2 m. This was based on using 160 mm diameter PVCu drainage pipework channelling air at 4 m/s. “Most people think that PVCu is quite a good thermal barrier,” says Todd. “But as it exchanges heat at a very low rate it enables the soil around the pipes not to become saturated with heat.” PVCu was chosen for a number of other reasons: it was available in the region, economic, durable, watertight and by installing it with a fall of 1:60 the tubes could be periodically jet washed.

Computational analysis showed that this set up should achieve a reduction in air temperature of 8°C at the ground tube outlets, in turn providing internal air temperatures 3°C below outside temperatures, which under most circumstances were considered sufficient for thermal comfort.

Installation and integration

Using the initial work carried out by ECD, Hurley Palmer Flatt took over the engineering of the scheme. One of the main concern s of HPF and project architect Jes Mainwaring was that traditional Portuguese wall construction might diminish the effectiveness of any heating or cooling energy gleaned from the ground tubes. Walls typically take the form of hollow lightweight terracotta blocks with a painted plaster finish and minimal insulation – in other words thermal mass is negligible, with limited capacity to store warmth or coolth.

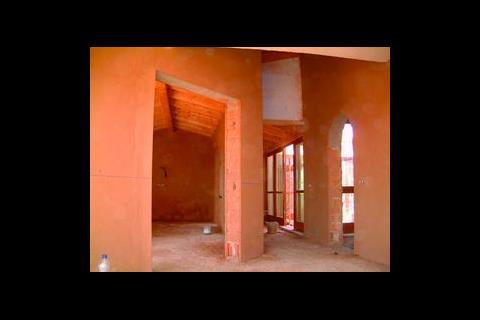

The team felt that a heavier weight solution was needed and so decided to construct the internal walls and inner leaf of the external walls from adobe (sun baked clay) blocks that were made on site. The walls were finished with a clay render, made from a fired clay hollow system; this uses interlocking vertical joints to avoid the need for mortar and allows the adobe blocks to breathe. Finishing this off is an external insulation system, which helps provide an overall U-value for the walls of 0.4 W/m2K. Like the roof (0.14 W/m2K), windows (4.2 W/m2K) and floor (0.89 W/m2K), the entire building envelope comfortably outperforms the standards set out in the Portuguese building regulations, something the design team knew would be needed to optimise the Coolhouse system.

From ECD’s initial studies it was also clear that direct wind power alone would not be adequate to achieve the duct velocities needed. A single 170 W variable speed air-handling unit is used to pull air though the ground tubes from an inlet chamber built into the north facade of each dwelling, and push it into a subfloor void. From this pressurised void, air exits through discrete slots around the perimeter of the floor slab, discharging directly into the space to be cooled. The slots are sized to suit the thermal loads of the spaces, with typical face velocities below 1 m/s. However, to get the most out of the relatively low cooling capacity, the intention is to run the system for relatively long periods, encouraging the cooling of the structure at night-time. “Because the system runs for long periods we needed to make it as quiet as possible,” says Todd. “The fan is sized to overcome the resistance of the pipes and ducts, but it’s still below NC25.”

During the heating season, outside air is still drawn in through the ground tubes, this time providing useful low-level ventilation preheat. Early monitoring indicates that the temperature of the incoming outside air is raised almost to the below-ground soil temperature. This pre-warmed air is then passed over a low temperature radiant heated skirting system that provides about 180 W per linear metre.

The system is simple to control: the primary controller is a timer that runs the system automatically to a preset time/duration. The second controller sets the system to winter or summer mode. Nuaire, which supplied the air-handling unit, provided a controller that links the fan unit controller to the heating system controls. In winter mode, when the fan is running and drawing in prewarmed air, the skirting heating system is automatically turned on to the dictates of the room thermostat. This overrides any preset heating timings and prevents intake of air at cooler than desirable temperatures.

Monitoring

The results that have come back from the early monitoring reveal that the system has far exceeded its expected internal air temperature reductions of about 3°C. Once the project was complete, two houses were monitored: one unoccupied with two independent ground cooling systems, serving living areas and bedrooms separately; the other a similar house occupied by a couple with a single system serving living areas only.

In the unoccupied house, temperatures of as much as 12°C below the outside air temperature were recorded over a one-week period. And over two months, a relatively consistent temperature of 25°C was recorded at a time when external temperatures were topping 38°C. Temperatures in the occupied house followed a similar pattern, although 1.5-2°C higher and with greater fluctuations as a result of the occupants and their activities, such as cooking (see figures 1 and 2).

However, it is the effect of the system on relative humidity that has been most startling. Relative humidity levels in south-west Portugal are frequently in the 80-85% band, often reaching 95%. “It is clear from the results that method of breathable construction using adobe, in combination with the Coolhouse system, is having a very significant impact on relative humidity levels,” says Todd. In fact, it is achieving reductions of 15-20% when external temperatures are high, with slight dips internally in mid-afternoon as external levels drop by up to 30%, indicating the ability of adobe to release entrained water vapour as the air dries out. During this 24-hour period the internal level remains within the 40-60% industry standard health band.

Results for the occupied house over a two-month period show relative humidity reductions of up to 30% at peak periods. While peaks and troughs occasionally exceed the 40-60% band, the trend remains within this zone, and it is hoped the gradual drying out of the new building will contribute to further reductions in this trend line.

“While this aspect of the construction is not central to the thermal performance of the Alma Verde ground cooling system, and the exact mechanisms by which the excess water vapour leaves the house are not known, it indicates distinct health benefits,” says Todd. “It also reduces energy demand by removing the need for dehumidification, which is the common local solution to the problem of high humidity.”

The Coolhouse system doesn’t provide reductions in temperature to precise thermostatically controlled levels in the same way as conventional air-conditioning, so is not suitable for use in commercial buildings. “In offices where you’ve got high internal loads, it’s not really feasible, no doubt about that” says Todd.

In domestic applications, however, its effective low-energy comfort cooling is a feasible alternative to air-conditioning. According to Todd, it comes down to client choice: you can have an air-conditioning system that will provide close temperature control, or, for a similar price, a low-grade cooling system that can trim temperatures to a comfortable level, using much less energy. “Clients need to understand that they are not looking at like-for-like systems,” he says. “It’s a system that doesn’t achieve the same design criteria but the question that needs asking is, do you really need to meet those criteria?” In a lot of cases, that answer is going to be no.

Just how bad could it get?

Residential air-conditioning accounts for about 90 million tonnes of CO2 emissions throughout southern Europe every year, according to the European Union. However, if this sounds like an alarming statistic, things could be about to get a lot worse.

Recent figures from BSRIA predict that the installation of single splits, multisplits and variable refrigerant flow systems are set to explode over the next three years. Italy in particular expects numbers to rise dramatically. The number of single splits installed is forecast to reach 2.5 million by 2008, up from half a million in 1999, while the number of multisplits installed is expected to be close to 1 million. Rapid growth is also anticipated in Spain, Greece and France. The result of these increases will be a massive hike in CO2 emissions.

Downloads

The Coolhouse ground cooling system for summer conditions.

Other, Size 0 kbFIGURE 1

Other, Size 0 kbFIGURE 2

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet