The initial idea for the Eden project began in late 1994, with the aim of creating a showcase of plant habitats from around the world. The emphasis though was as much on education and research as it was for creating a tourist attraction.

Work began on-site in late 1998 following a £43 million grant from the Millennium Commission, with the project fully opening to the public in March 2001.

The site and structure

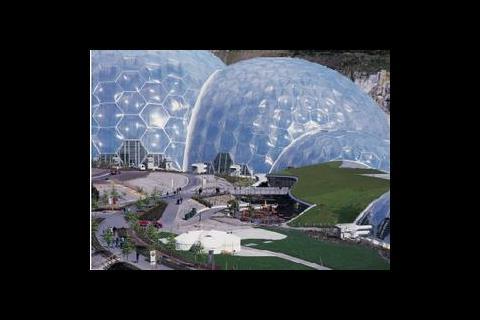

The two climate controlled biological domes, (biomes) make up the centrepiece of the project. These consist of the humid tropics biome (htb), representing rainforest environments drawn from Amazonian, West Africa, Malaysia and the Oceanic Islands and the warm temperate biome (wtb), filled with flowers, vineyards, citrus and olive groves from the Mediterranean, California and South Africa. Plans to build an arid tropic biome were put on hold due to a lack of funding. The roofless biome makes up a third zone and is home to plants from the Himalayas, Chile and Australia able to survive outside in Cornwall's mild climate.

The two biomes are linked by a low level 500 seat open plan restaurant, with direct access via an overhead walkway. This space is not highly controlled, relying on natural ventilation and a perimeter heating system run off the site's heating ring main.

The project also incorporates a visitor's centre situated on the southern lip of the pit which houses the ticketing zone, shop, café and toilets. The front of the building is clad in cedar shingles, while the rear wall is a rammed earth construction, using clay from the site. Again the space is not highly controlled, being open to the elements throughout most of the day.

Designed by architects Nicholas Grimshaw and Partners and structural engineers Anthony Hunt Associates, each biome is made up of four intersecting geodesic domes which are moulded to the contours of the pit, effectively creating a pair of massive lean-to greenhouses.

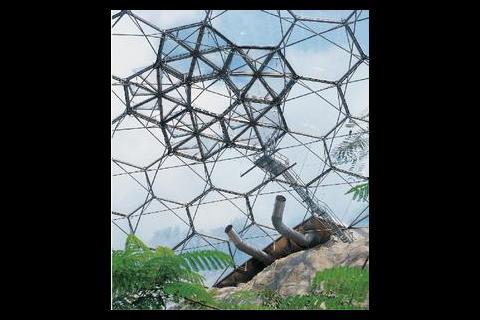

The double layer tubular steel spaceframe that makes up the skeleton consists of an outer latticework of hexagonal elements which support the lightweight cladding system, while the inner frame provides the structural rigidity. Neither of the biomes has any internal supports, the htb reaches 55 m at its highest point and measures 240 m long and 110 m wide, enclosing an area of 15 590 m2, the smaller wtb measures 35 m high, covering a total area of 6 540 m2.

Environmental engineering

"The first thing we had to do was understand what conditions were needed in the biomes to get maximum benefit for the plants," explains Alistair Guthrie Arups' m&e project director. It wasn't a case of replicating what is found in nature, nor was it about creating a uniformly controlled environment – typical of a commercial greenhouse.

Working with a team of horticulturists Arup built-up a picture of optimum climatic conditions for each space during the course of a year in terms of humidity, temperature and light as well as the desirable changes in these conditions and the drop dead temperature, for example, the temperature that would cause permanent damage to the plants.

Comparing these figures with the naturally occurring conditions in Cornwall the team sought to trap as much solar gain as possible - particularly to elevate winter temperatures within the space. Consideration was also given to storing this thermal energy. One of the factors in choosing the site was the long, virtually south-facing expanse of rock against which the biomes are built. Modelling showed that this would provide good passive thermal storage.

Active storage was also considered but the minimal benefits to be had from installing such a system could not be justified in terms of capital costs.

The design team also wanted to maximise the light coming into the space but still improve the thermal performance of the envelope. The solution was to clad the domes with ethyltetrafluoroethylene (etfe) – a transparent foil which has been around for the last 20 y. A single layer has 95% light transmission and, at 200 microns thick, it is around 1% the weight of glass.

To create the hexagonal panels, three layers of film are bonded along their edges and pressurised with air, thereby creating a 'pillow' capable of withstanding windloads. The 2 m deep 'pillows' are connected to a compressed air system via a network of pipes attached to the steel space-frame,and are pressured to between 60 Pa and 200 Pa depending on the size and the temperature of the air. Each panel achieves a U-value of 2·7 W/m2K, at least equivalent to double glazing. A further benefit of etfe is that the material repels dirt, making it self-cleaning.

Having created these relatively airtight biomes there would obviously be certain times of the year when there is not sufficient energy to heat the space to the minimum required temperatures. In order to prevent disrupting the biome's growing space Arup resorted to technology it had developed for the Kansai Airport project.

A series of air handling units are located externally around the perimeter of the biomes. A total of 24 units are installed on the htb at ground and high level (where the dome meets the rock face) while the smaller wtb makes do with nine units. These feed long-throw air jets which are angled to blow air across the underside of the pillows, causing entrainment currents within the space and allowing for good mixing. Ducts for the return air are mounted alongside.

A large three dimensional cfd model was set-up to confirm that the basic strategy worked and establish the air's circulation current and mixing. The exercise also allowed the positioning and angles of the air nozzles to be fine-tuned, this was necessary as a number of the ahus needed repositioning because of awkward site conditions. It also resulted in the high level ahus in the wtb being omitted.

A ring main provides hot water to the ahus from a central energy store situated on the top northern side of the pit. Various methods of generating heat energy were looked into. Cogeneration was discounted on the grounds that the site didn't have a big enough electrical load to match the heating needs, and Guthrie's favoured choice of a biomass boiler was dropped because of costs. Interestingly, the original plan had been to install the biomass system alongside the biomes as a demonstration to visitors, however windtunnel tests showed that it couldn't be guaranteed that the combustion gases would clear the pit.

Consequently three gas-fired boilers have been installed each with a capacity of 3 MW, providing a 92°C flow, 80°C return supply. The peak design conditions in terms of heating is approximately six times the average requirements.

Obviously in certain conditions overheating could be a major problem. The solution has been to use natural ventilation. Banks of double glazed glass louvres have been incorporated around the base of each biome and these work in sequence with motorised opening lights at the apex of each dome. The height of the spaces ensures that the stack effect is more than adequate to maintain the desired conditions. During high-gusting winds the opening lights will automatically close in order to prevent structural damage. In these situations the ahus switch to fresh air mode.

Water services

Ground water is collected for toilet flushing, irrigation and to provide fire services – although in the case of a major fire there is a backup mains supply. From the groundwater collection system water is pumped to a 100 000 m3 bulk greywater storage tank under the biome link building, which also houses the main pump plant room. This is filtered to 50 microns before undergoing uv treatment and passing into a buffer tank for distribution around the site.

A substantial water supply was also required for humidification of the htb. The system relies on misting nozzles connected by flexible pipes to servicing points throughout the planting areas. These are positioned by the horticulturists to create the appropriate microclimate for the surrounding plants. It was stipulated that this should be as pure a water supply as practicable and as ground water is susceptible to cross contamination it was decided to recycled rainwater collected from the biomes should be used. A closed channel drainage system was installed around both biomes to collect and transfer rainwater to two 120 m3 holding tanks. From here the water is filtered and pumped to three 568 m3 existing refurbished concrete tanks at the top of the quarry, previously used for storing china clay slurry.

Naturally there were concerns regarding public health with the misting system, however there was also a conflict between pure disinfection and what the plants could tolerate – chlorine was not an option. It was d use a silver ion disinfection system. Water entering the first storage tank is dosed with a silver ion liquor before passing through the middle tank and into the final tank where the process is repeated.

Where this system differs from other silver ion disinfection systems is in the use of a monitoring system: silver dosed liquor is made up to a specific concentration and the system senses the dose required for the particular volume of stored water, thereby providing a greater degree of flexibility and control.

From the storage tanks the water is gravity fed down to the htb and into the high pressure (120 bar) misting system. Up to eight weeks of water storage is available although the system can switch to mains water if required. Ground water for the toilet flushing also undergoes a similar silver ion treatment.

Within the wtb there is a waterfall with a 60 l/s cascade which flows through a series of landscapes and channels into a lagoon from where it is recirculated, with top up from the rainwater collection system. As the system is permanently circulating (it's throttled back to 20% flow at night) it is treated using a uv system on a 20% sidestream system, sufficient to keep it clean. Energy from the waterfall also generates additional wind movement for the plants.

Control of the opening vents and the humidity in the biomes is achieved using a horticultural control system which looks at the macroscopic conditions in the space. This measures temperature and humidity at the top and bottom of each of the interlinked domes.

A 1 MW emergency standby diesel generator provides power to the essential systems to maintain conditions within the biomes in event of a power failure. A central battery back-up is installed for the path and an emergency exit lighting system installed throughout.

The future

Despite cost restraints, the unconventional structures and particularly challenging construction conditions, the Eden Project has transformed an industrial wasteland into an instantly recognisable landmark.

The biomes have yet to be tested by a scorching summer or a harsh winter, but so far the horticulturists are happy with their artificial environments and are fine-tuning the control system. Eden has certainly caught the public's imagination. Original visitor projections of 750 000 a year now looking to top 2 million which will no doubt put a strain on infrastructure, but it will make a sound argument for the building of the arid biome.

The Eden Project, Bodelva, St Austell, Cornwall

Engineering dataArea enclosed:

- humid tropics biome 15 590 m2

warm temperate biome: 6 540 m2

Energy centre: 330 m2, mechanical, electrical and pump

Biome link:

- 195 m2 mechanical

76 m2 pump

Winter: -3°C db

Summer: CIBSE coincident temperature and radiation for South East England and CIBSE example weather year for Camborne. Internal design conditions

Winter

Warm temperate biome:

- 19°C max

13°C min (daytime),

4°C min (night-time)

drop dead 2°C

- 23°C max

20°C min (daytime)

18°C min (night-time)

drop dead 10°C.

Warm temperate biome:

- 32°C max

20°C min (day)

13° (night)

drop dead 4°C

- 35°C max

22°C min (day)

19° min (night)

humidity 85%

ETFE pillows: 2·7 W/m2K

Loads

Installed heating load: 9 MW

Peak plant load (htb) 1 150 kW

Peak plant load (wtb) 490 kW

Ventilation

Primary air volumes

Warm temperate biome

1 ahu @ 2m3/s

4 ahus @ 3·5 m3/s

4 ahu @ 6·5 m3/s

Total: 42m3/s

Humid tropics biome

2 ahus @ 2·5 m3/s

17 ahus @ 5 m3/s

3 ahus @ 6·7 m3/s

2 ahus @ 7.5 m3/s

Total 125·1 m3/s

Distribution circuits

LTHW: 92°C flow, 80°C return

Costs

Total cost: £54.915 million (gross maximum price) including £2.313 million external infrastructure services and drainage. Building services total: £6.494

No breakdown of the mechanical and electrical services cost was available.

Downloads

Plan of Eden

Other, Size 0 kbBiome thermal control

Other, Size 0 kb

Source

Building Sustainable Design

Credits

Client Eden Project Project manager Davis Langdon Management Architect Nicholas Grimshaw and Partners M&E consulting engineer Arup Structural engineer Anthony Hunt Associates Civil engineer Anthony Hunt Associates M&E contractor MJN Colston Main contractor McAlpine joint venture (Sir Robert McAlpine/Alfred McAlpine Construction) Quantity surveyor Davis Langdon & Everest