This CPD, sponsored by Kingspan Insulation, looks at different types of insulation products for masonry cavity walls, how energy efficient they are and the cost implications of choosing one product over another for projects of varying sizes

CPD CREDITS: 60 MINUTES

DEADLINE: 5 JULY 2019

For more information about Assemble Media Group’s CPD distance-learning programme, click here

Introduction

Achieving value for money is a fundamental ambition for any project team. Too often, however, this can lead to “value engineering” where cheaper, lower-performing materials are added into a project as a way of reducing costs. In addition to the obvious issues this raises for the overall quality and performance of the building, the differing properties of these products can also lead to costly changes in the design.

New research from Currie & Brown has shown that when overall costs are considered, it can often be cheaper to install premium performance phenolic cavity wall insulation over cheaper, thicker materials such as glass mineral fibre insulation.

This CPD will examine various types of insulation products for masonry cavity walls, their energy efficiencies and the cost implications for choosing one product over another.

Cavity considerations

Masonry cavity wall approaches are the preferred method of housebuilding for many developers in the UK. The tightening of the Building Regulations and Standards relating to energy efficiency state that walls must be insulated to a high standard. For new homes, these requirements are covered within Approved Documents L1A to the Building Regulations 2013 (in England), 2014 (in Wales), and Section 6 (Energy) 2015 of the Building Standards (in Scotland).

To ensure compliance, it is a good idea to target an external wall U-value of 0.16 W/m²·K for properties in England and Wales and 0.15 W/m²·K in Scotland. A wide variety of cavity insulation products are available to achieve this. When specifying these items, it is important to consider what the thermal conductivity (lambda value) of the material is. This is the measure of how a material conducts heat. Materials with a low thermal conductivity value are more resistant to heat loss through conduction, meaning a reduced thickness of insulation can be used to achieve the same level of thermal performance.

Cheaper materials often have relatively high thermal conductivities. For example, the typical thermal conductivity of glass mineral fibre cavity wall insulation is between 0.032-0.037 W/m·K. In contrast, the latest phenolic insulation boards have a thermal conductivity of just 0.018 W/m·K. Therefore, while the insulation boards themselves are more expensive than lower-performing materials, they can enable the desired U-value to be reached using thinner insulation and thus creating a thinner overall external wall construction. This can have a significant impact on other areas of the construction, such as the size and cost of foundations.

To understand how this may affect overall project costs, Kingspan Insulation commissioned construction consultancy Currie & Brown to carry out an analysis.

Scenarios

To assess how the choice of insulation could impact overall project costs, Currie & Brown developed scenarios for properties of three different scales:

- Large detached house

- Small detached house

- Mid-terraced house

Each property was modelled using SAP 2012, the government’s standard assessment procedure to evaluate the energy rating of dwellings. The procedure considers various aspects of the energy expenditure that goes into heating a home including space heating, water heating, ventilation and lighting.

Each of the houses was designed to meet the requirements of Approved Document L1A Building Regulations 2013 (England) with an external wall U–value of 0.16 W/m2.K. Two external wall specifications were developed for each scenario, one with glass mineral fibre insulation and the other with premium performance phenolic insulation. The full specifications are shown in Table 1.

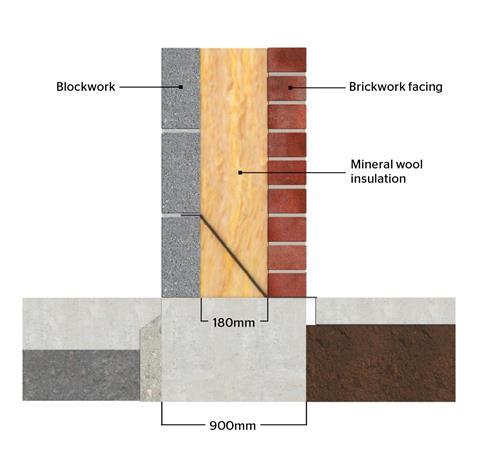

The phenolic insulation board features a water-tight, vapour-open polypropylene fleece outer facing supported with a 10mm residual cavity, which protects against moisture penetration. The higher thermal conductivity of the glass mineral fibre insulation meant that the cavity depth had to be increased by 80mm relative to the phenolic construction to achieve the target U-value.

| Specification | Thickness (mm) |

|---|---|

Brick outer leaf (102.5mm)

|

302.5 |

Brick outer leaf (102.5mm)

|

382.5 |

Cost variables

A cost analysis was then conducted by an experienced residential quantity surveyor. In addition to the up-front cost of the insulation

and associated products, the analysis considered a wide range of variables related to the varied cavity width and external wall constructions. These included:

- Foundation length with associated effects on concrete, reinforcement, excavation, disposal and backfill quantities;

- Length of external perimeter of foundations with implications for formwork area;

- Length of external perimeter of the outer wall layer with implications for the area of brickwork in groundworks and external walls;

- Width of cavity closers, trays and lintels;

- Length of wall ties;

- Length of roof rafters and joists;

- Length of fascia boards and guttering;

- Area of roof covering (including slates, membrane and battens);

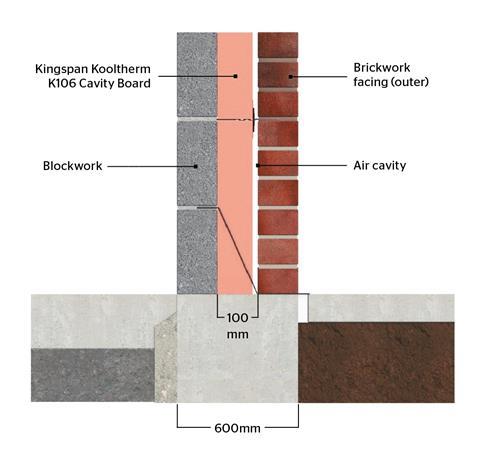

- Foundation width. All options were modelled with a standard foundation width of 900mm with 750mm and 600mm options considered for the scenarios with 100mm cavities.

In all scenarios, the internal area of the home was kept constant with the impact of varying cavity width seen entirely on the external footprint. The homes have timber roof structures finished with slate tiles.

Foundations are 300mm deep in a 600mm trench. It was assumed that the thinner cavity for the phenolic insulation specification would allow a narrower foundation of 650mm compared with 900mm for the glass mineral fibre specification as shown in Figures 1 and 2. All costs within the analysis were based on costs current to the third quarter of 2017.

Results

The analysis showed that while the cost of the glass mineral fibre insulation itself was less than the phenolic insulation, the increased cavity width with the glass mineral fibre specification raised the cost of all accessories as shown in Table 2.

| Component | Unit | Cavity width 100m | Cavity width 180mm |

|---|---|---|---|

| 90mm phenolic cavity wall insualtion (inc tape) | m2 | £32.50 | |

| 180mm glass mineral fibre cavity wall insulation | m2 | £14.00 | |

| Wall ties | m2 | £3.33 | £4.51 |

| Closers | m2 | £5.68 | £6.43 |

| Trays | m2 | £2.66 | £3.42 |

| Lintels | m2 | £10.92 | £12.27 |

Furthermore, the glass mineral fibre construction added significantly to the scale of the build programme. In addition to more extensive foundations and associated groundworks, the need for wider cavities and thicker walls also led to an increase in the external wall areas as detailed in Table 3.

It was found that the use of glass mineral fibre saw an increase in length of the outside wall, width to the outside wall and cavity thickness in all three of the different domestic new-builds. Using glass mineral fibre also meant an increase in total external wall area (minus openings), external area (excluding gable ends) and external perimeter for the large and small detached houses.

| Dimension | Large detached house | Small detached house | Mid-terraced house | |||

|---|---|---|---|---|---|---|

| 100mm cavity | 180mm cavity | 100mm cavity | 180mm cavity | 100mm cavity | 180mm cavity | |

| Length to outside of wall (m) | 9.6 | 9.76 (+0.16) | 8.9 | 9.06 (+0.16) | 7.98 | 8.14 (+0.16) |

| Width to outside of wall (m) | 8.8 | 8.96 (+0.16) | 5.25 | 5.41 (+0.16) | 4.63 | 4.79 (+0.16) |

| Cavity thickness (m) | 0.1 | 0.18 (+0.08) | 0.1 | 0.18 (+0.08) | 0.1 | 0.18 (+0.08) |

| Height to eaves (m) | 4.73 | 4.65 | 4.73 | |||

| Total external wall area minus openins (m2) | 185.44 | 188.69 (+3.25) | 156.22 | 159.86 (+3.64) | 31.76 | 31.76 (-) |

| External area excl gable ends (m2) | 167.65 | 170.9 (+3.25) | 118.92 | 122.57 (+3.65) | 31.76 | 31.76 (-) |

| External perimeter (m) | 39.67 | 40.31 (+0.64) | 28.3 | 28.94 (+0.64) | 9.25 | 9.25 (-) |

When all these factors were considered, the analysis showed that the overall cost for the large and small detached houses with the phenolic insulation specification and 600mm foundation was actually less than that of the glass mineral fibre specification with a 900mm foundation (as shown in Table 2).

For the mid-terraced property, the cost differential was almost identical, with the phenolic construction costing just £4 more than the glass mineral fibre specification. The mid-terraced property performed differently due to the area of insulated external wall being significantly reduced because of the two-party walls.

In addition to these cost benefits, the reduced construction thickness of the phenolic insulation specification may also help to increase natural light levels within the space. Research from consultant Peutz BV has shown that by installing phenolic insulation over glass mineral fibre alternatives, external wall and window reveal depths can be reduced. This can help to improve daylight levels within a room.

The research looked at a range of facade arrangements and found that the percentage improvement in the average daylight factor when using the phenolic construction over glass mineral fibre ranged between 10.6% and 63.2%. This can provide a healthier space for occupants and may make them more attractive and saleable to potential buyers.

| House type | 100mm cavity phenolic insulation specification with 600mm foundation | 180mm glass mineral fibre specification with 900mm foundation |

|---|---|---|

| Large detached | £53,993 | £54,154 (+£161) |

| Small detached | £41,324 | £41,744 (+£420) |

| Mid-terraced | £9,801 | £9,797 (-£4) |

A holistic view

With constant pressure on the bottom line, it is understandable that architects and project teams look to find cheaper solutions where possible – particularly when the material itself will not be visible to potential owners. The research from Currie & Brown shows, however, that selecting materials purely based on their shelf price can lead to unforeseen additional costs as well as compromises in design. By taking a more holistic look at how products such as insulation can impact other areas of a project, it may therefore be possible to specify more premium options and achieve improved performance and quality while still saving money overall.

How to take this module

Assemble Media Group’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 5 JULY 2019

Privacy policy

Information you supply to Assemble Media Group Limited may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. Assemble Media Group Limited may send updates about Building CPD and other relevant Assemble Media Group Limited products and services. By providing your email address you consent to being contact by email, telephone, fax or post by Assemble Media Group Limited or other third parties. If at any time you no longer wish to receive anything from Assemble Media Group Limited or to have your data made available to third parties, contact the Data Protection Coordinator at building@building.co.uk. View our full privacy policy her

No comments yet