Steel offers sustainability credentials through the whole life-cycle of a building, and is an excellent choice of framing material to deliver high-scoring BREEAM projects. This CPD module, sponsored by Steel for Life, outlines the main points to consider

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 5 MAY 2017

INTRODUCTION

A recent survey identified that over 66% of multi-storey, non-domestic buildings are framed in structural steel, making it the preferred framing solution for many of the UK’s structures.

An increasing number of these buildings achieve high sustainability ratings and targets.

This CPD article will examine a number of steel’s sustainability credentials – both established and emerging – including its:

- off-site manufacturing process

- flexibility and adaptability

- performance in regard to embodied carbon

- ability to be re-used, recycled and multi-cycled

- alignment with circular economy principles.

OFF-SITE MANUFACTURING

All steel components are manufactured off-site in the controlled environment of a fabrication factory, and then assembled on site. The off-site manufacturing process is faster and leaner than traditional site-based construction.

Off-site steel fabrication also has benefits for the workforce as it requires skilled, settled workers, so offers long-term employment for a specialist workforce, benefiting local communities. Compared with working on-site, the steelwork fabrication factory is also a safer environment for staff; and productivity and quality are not subject to the elements as site-based construction is.

In the factory, sophisticated design and production systems deliver precision-engineered components in a controlled, highly regulated and safe environment. Any waste material produced during fabrication can be recycled and used again in the steelmaking process.

Fabricated steelwork is delivered to site as and when required, reducing the need for on-site storage, substantially reducing site waste and disruption to other trades and neighbours. The off-site process means products have few defects, which leads to less “snagging” on site, resulting in savings in time and money.

The government-commissioned Farmer Review into construction industry efficiency, published in October 2016, identified off-site manufacturing as central to modernising the industry.

Its benefits include improved innovation, research and development, sustainability and speed of delivery. Trade body Buildoffsite has identified time savings of 50% to 60% for projects with high repeatability, such as hotels and prisons, and 25% to 30% for more complex schemes such as offices or retail.

FLEXIBILITY

In an era of changing work patterns, new technologies, changing demographics and legislation, the need for flexible buildings has never been greater. Steel’s inherent strength, and the long spans possible in steel-framed buildings, give architects scope to create innovative and flexible buildings, which can be easily adapted to suit changing workplace or lifestyle requirements.

Additionally, the use of cellular steel beams allows easy integration of both current and future servicing requirements, minimising floor-to-floor heights and extending the life of the building.

There are many examples of modern steel-framed buildings that have been designed with flexibility in mind, usually featuring large, open-plan spaces that can be easily reconfigured with lightweight partition walls. The St John Bosco Arts College in Liverpool is one example. Eleven large trusses support the roof and create a 55m-wide, column-free space, which can be divided up according to education needs using movable partition walls.

A steel frame can be easily adapted, with parts added or taken away, and its light weight means that extra floors can often be added without overloading existing foundations. Alternatively they can be strengthened or extended both horizontally and vertically.

BREEAM

Steel-framed buildings routinely achieve high ratings after being assessed under BREEAM and will support gaining credits within the materials section of the environmental rating system.

A number of steel upper floor, external and internal wall systems commonly used in commercial and industrial buildings achieve an A or A+ rating in the Green Guide to Specification.

Central Square, a 12-storey steel-framed development in Leeds, achieved a BREEAM “outstanding” rating last year and was shortlisted for the 2017 BREEAM awards. The 20,400m2, office-led building uses almost 2,000 tonnes of structural steel, with large spans creating spacious floor plates and giving greater flexibility to tenants. Brent Civic Centre and the Co-operative Head Office in Manchester are other examples of BREEAM “outstanding” steel projects.

BREEAM “excellent” ratings have been achieved by steel-framed buildings across a range of sectors, including offices, industrial, healthcare and education.

EMBODIED CARBON AND LIFE-CYCLE ASSESSMENTS

In recent years the impact of carbon has moved beyond solely addressing a building’s operational carbon, and embodied carbon has drawn much greater scrutiny and importance.

The term “embodied carbon” refers to the life-cycle greenhouse gas emissions that occur during the manufacture and transport of construction materials and components, as well as the construction process itself and end-of-life aspects of the building.

Embodied carbon assessment is part of a broader discipline called life-cycle assessment (LCA), which covers a range of different environmental impacts, including energy and material inputs and end-of-life processes.

An important sustainability consideration when specifying construction materials is the type of LCA used. Some, called “cradle-to-gate”, only assess the impact of embodied carbon to the point where the product leaves the factory gate. It is generally recognised that more robust assessments are “cradle-to-cradle” impacts, which measure all life cycle phases, including the building’s demolition and disposal of the materials as waste or through recycling and re-use. Cradle-to-cradle assessments can be carried out using the BS EN 15804 and ISO 14044 standards.

So how does steel perform? The high strength-to-weight ratio of steel minimises frame weights – and therefore foundation requirements – both a key source of embodied carbon. Although steel, in terms of carbon emissions per tonne of material, will usually score higher than other materials, its strength properties mean much less of it will be used in a structural frame compared with other materials. Put simply, a little steel goes a long way. Target Zero, a report by a consortium of organisations including Tata Steel, Aecom, SCI, Cyril Sweett (now Currie & Brown) and BCSA, demonstrated this in a study of several different building types, each one using a different framing material (see table 1, below).

Table 1: Embodied carbon per square metre (kgCO2e/m2)

| Building type | Steel | Concrete | Timber | |||

|---|---|---|---|---|---|---|

| Whole building | Structure only | Whole building | Structure only | Whole building | Structure only | |

| School | 301 | 118 | 344 | 156 | - | - |

| Multi-storey office | 452 | 219 | 506 | 266 | - | - |

| Multi-storey mixed use | 395 | 218 | 467 | 259 | - | - |

| Warehouse | 234 | 32 | - | - | 266 | 59 |

| Out-of-town supermarket | 376 | 58 | - | - | 384 | 66 |

Detailed reports for each of the five buildings are available at www.steelconstruction.info/Target_Zero

OPERATIONAL CARBON: STEEL AND THERMAL MASS

The impact of structural form on the operational carbon emissions from non-domestic buildings is generally small – however, an issue that should be acknowledged is thermal mass.

A common misconception is that heavyweight concrete structures are generally more energy efficient because of their greater massing. The variation in operational carbon between steel and concrete frames is 1% or less in all cases. Steel frames can also provide optimal slab thickness to utilise thermal mass. Thermal mass describes the ability of the fabric of a building to absorb and store heat. Used effectively, it can reduce cooling loads and, in some cases, remove the requirement to provide air conditioning and supporting initiatives to reduce operational carbon.

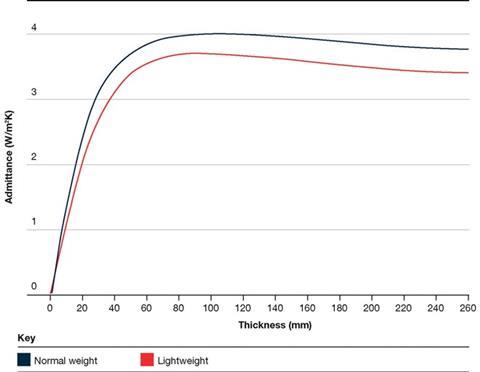

The most commonly used parameter for assessing the potential thermal mass of building elements is admittance, which can be defined as the ability of a building element to exchange heat with a space when it is subject to cyclical variations in temperature. Figure 1 (see below) shows the variation in admittance with increasing depth for normal and lightweight concrete. It shows that, in a naturally ventilated building, the maximum value of admittance for a concrete slab exposed on one side is achieved with only 75-100mm of concrete.

In multi-storey buildings the upper floors are the most important element providing the greatest “accessible” thermal mass. Whether the building is steel or concrete framed, the upper floors are generally concrete, either cast in-situ or precast and therefore utilising the thermal mass in the upper floors does not restrict the choice of framing material. All of the standard floor types used in steel-framed buildings can form the basis of an effective passive or active fabric energy storage system since their floor slabs are thicker than 100mm.

Figure 1: Thermal admittance against thickness for an exposed, flat concrete floor slab - 24-hour diurnal cycle

RECYCLING, RE-USE AND THE ‘CIRCULAR ECONOMY’

Maintaining products for as long as possible is a key component of the “circular economy”. The longer a product lasts, the less raw materials will need to be sourced and processed and less waste generated. Steel structures, when properly designed and protected, provide impressive long-term durability, as demonstrated by the National Liberal Club in London (built in 1887) and the Forth Rail Bridge (1890) – both still in use.

However, steel can be reused and recycled easily. The constructional steelwork used in the UK contains an average of 60% recycled content. Current recovery rates from demolition sites in the UK are 99% for structural steelwork and 96% for all steel construction products – figures that far exceed those for any other construction material.

Reusing simple, low-rise structures such as portal frames is relatively common in the agricultural sector.

Steel re-use can happen in three ways:

- In-situ re-use in which the structural frame is reused, with or without alterations, in situ. This is generally associated with refurbishment projects and it is currently the most common way of reusing structural steel in the UK

- Relocation reuse involves deconstruction of an existing steel frame, which is then transported and re-erected, generally in its original form, at a different location for the same or similar purpose

- Component reuse involves careful deconstruction of an existing structure where individual structural steel members are reclaimed and used to construct a new permanent structure.

The wide use of BIM models on steel-framed buildings also allows for greater certainty in re-use of existing components. Steelwork contractors have been using BIM models for years and routinely offer their clients as-built structural models on building handover. By storing such models in a secure database, this will future-proof UK steel structures and will assist with refurbishment, extension and eventually deconstruction of the building to facilitate re-use of the steel elements or optimising the recycling process.

At the end of a building’s useful life, its steel frame can be easily dismantled and elements of it either re-used or recycled. Steel used in construction will not go to landfill as even scrap steel has a value and is a vital element in the process of producing new steel. Steel can be recycled in this way infinitely as successive recycling does not reduce its qualities – it is not merely recycled, but multi-cycled.

The EU’s Circular Economy Package, launched in 2015, proposes tougher rules for waste and covers the full life cycle from production and consumption to waste management and the market for secondary raw materials. Construction and demolition waste, accounting for around 31% of total waste generation, has been identified as a priority waste stream.

The package is likely to promote greater use of cradle-to-cradle product LCAs.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 5 MAY 2017

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about Building CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at www.building.co.uk/cpd