This CPD, sponsored by Avonite, will outline the design of solid surface facade systems, their installation and maintenance, and examine regulatory requirements

CPD CREDITS: 60 MINUTES

DEADLINE: 19 APRIL 2019

For more information about Assemble Media Group’s CPD distance-learning programme, click here

Introduction

The attributes of a solid surface facade system include aesthetic appearance, ease of maintenance and colour fastness. Being compatible with virtually any insulation system, substrate and load-bearing profile, solid surface facade panels are particularly versatile in new builds and renovation.

This CPD will outline the design of solid surface facade systems, their installation and maintenance, and examine regulatory requirements.

Materials

The resins used in solid surface products are typically polyester or acrylic, or a blend of the two. Polyester resin is a thermoset polymer. It is malleable until it is cured, while acrylic resin is thermoplastic, pliable above a certain temperature but becoming solid upon cooling.

For solid surface products with acrylic resin, aluminium tri-hydrate (ATH) filler powder is essential to enable cutting, shaping and sanding. Without the filler, acrylic resin is useful for other applications such as bathware and signage where acrylic sheet is thermoformed, not machined.

Solid surface products made with polyester resins do not require ATH filler in order to be machined. ATH filler in acrylic sheet allows the product to have better fire resistance at the expense of translucency.

One advantage of a solid surface panel is its flexibility in fabrication. Several options are available, starting with backlighting. Some manufacturers offer sheets of material that are more translucent. Alternatively, it is possible to mill patterns into the sheet.

Interaction of components

The fire performance of a facade system depends on the interaction of all the components – including fixings, fasteners, sealants, railing systems and insulation – and on other design and construction factors such as the position of fire barriers, the size of ventilation gaps and so on. Any railing system and insulation should be non-combustible.

A solid surface manufacturer would usually recommend a specific fixing system, that goes along with its facade certification.

Design

The design elements of a panel can change the appearance of a building. In a number of situations panels can be backlit, including diffused projection, a ‘pixels’ look, a ‘total facade’ look – effectively an homogeneous facade, one without sharpness – and a punctual milled pattern, where a pattern is drilled into the product, enabling light to come through.

When it comes to backlighting there are two principal methods: a direct lighting model with an LED rail to gain a pixelized effect, and an indirect lighting model which can be used with LEDs projected onto a reflective surface to create a diffused lighting effect.

Types of fastening joints

In order to give a dynamic effect to a flat facade, special fastening systems can be used with the assistance of the fabricators. For various designs, different types of joints are possible. Some show the support structure, while in others this is entirely hidden.

There is always one consistent element: enough space must be left for the material to expand and to contract, as determined by the prevailing weather conditions.

Anchoring systems

One fastening system used to install façade panels is ETA-certified and allows what is known as ‘invisible anchoring’. This is another advantage with regards to the conception of a designed facade. It also has an extra benefit; since it is protected by the panels themselves, the anchoring system lasts longer.

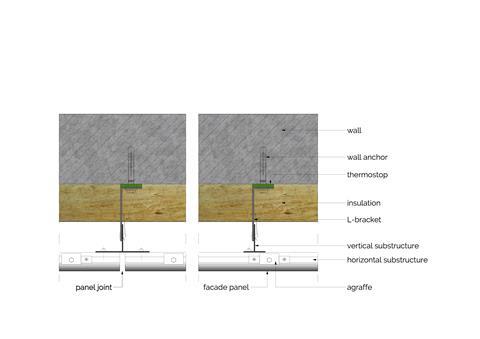

Here we see a fixing system with two elements – the ‘Keil’ inserts and the load-bearing profiles. (see above).

Load-bearing profile

The installation frame is fairly common – some manufacturers recommend standard BWM profiles for a flat facade and shape profiles for a thermoformed façade.

The vertical profiles are fixed on the load-bearing brick or concrete wall and through the insulation layer, while the horizontal profiles are fixed on top of the vertical profile.

Agraffes – or clasps – are fixed with the Keil anchors on the facade panels. With these the panels can be adjusted and installed to the horizontal profiles.

Installation

Prior to installation, facade sheets will require a light finish sanding in order to obtain an even appearance. Sheets should be trimmed to the required length, width and edge profile.

Each façade panel is fixed with at least four anchors in a rectangular arrangement via single agraffes to the sub-structure. The sub-structure is constructed in such a way that the facade panels are fixed effectively ‘strain-free’ via skids – effectively loose bearings – and one fixed bearing.

The façade panels are arranged in a ‘reclined’ or ‘upright’ position. They may also be fixed at facade soffits.

Two anchor points of the facade panel are designed so they are able to carry the load of the facade panel. The load-bearing profiles are arranged symmetrically, while the arrangement of the agraffes ensures a symmetric introduction of the load into the substructure.

When using agraffes on horizontal load-bearing profiles the fixing points of a facade panel – situated horizontally at the same height – are in each instance fastened to the same load-bearing profile.

It should be noted that the facade panels are not used to transmit impact loads or to act as guard rails.

Specifying solid surfaces on a ventilated facade

When suitable fire resistance is required manufacturers can recommend and provide a NF P 92-501 Class M1-certified formulation.

In terms of performance the characteristic values of a facade panel are set out in the table below, as are the characteristic values of the anchor.

| Characteristic of facade panel | Panel thickness | h= mm 12 |

|---|---|---|

| Characteristic resistance to bending stress | ợrk = N/mm² 39,11 | |

| Partial safety factor (1) | ym = 2,0 | |

| Modulus of elasticity | E = N/mm² 8000 | |

| Thermal coefficient | aT 1/˚C 3,76 * 10-5 | |

| Density | Y= g/cm³ 1,73 | |

| Resistance to water | % 0,04 | |

| Frost resistance | yes | |

| Characteristic values of the anchor | Characterstic resistance to tension load (2) | Nrk 5% = 2,12 |

| Characterstic resistance to shear | Vrk 5% = 5,42 | |

| Setting depth | h5 = 7,0 | |

| Edge distance (3) | arx or ary ≥ 100 | |

| Spacing | ax or ay ≥ 200 (4) | |

| Partial safety factor | ym = 2,0 |

| (1) In absence of other material regulations |

| (2) In case of coincident stress of an anchor due to tension and shear load following equation shall be observed: (see equation on sheet!) |

| (3) For small fixed piece, differential and fill-in pieces, the edges distance and spacing shall be chosen constructively |

| (4) The maximum of distance is governed by the load-bearing capacity of the panel and determined through the static calculation |

Formats

The usual dimensions of facade panels are (thickness) 12mm x (width) 762mm x (length) 3,658mm, while other standard widths are 914mm, 1,372mm and 1,520mm.

How to take this module

Assemble Media Group’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 19 APRIL 2019

Privacy policy

Information you supply to Assemble Media Group Limited may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. Assemble Media Group Limited may send updates about Building CPD and other relevant Assemble Media Group Limited products and services. By providing your email address you consent to being contact by email, telephone, fax or post by Assemble Media Group Limited or other third parties. If at any time you no longer wish to receive anything from Assemble Media Group Limited or to have your data made available to third parties, contact the Data Protection Coordinator at building@building.co.uk. View our full privacy policy here

No comments yet