Correct specification and installation is critical to the performance of a steel lintel. This CPD, sponsored by Catnic, outlines the main points to consider

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 27 JANUARY 2017

INTRODUCTION

Steel lintels are used in many building applications, and products are available to suit a wide range of wall constructions. The correct choice will depend on many factors including construction type, loadings, required thermal performance and building location. Correct installation is also critical to a steel lintel’s performance. This CPD will discuss considerations for the specification of steel lintels, and the key criteria for a successful installation.

DESIGN CONSIDERATIONS

The NHBC will approve for use any product that has been accredited with a satisfactory assessment by an independent testing approvals authority. All steel lintels must also be CE marked, in according with BS EN 845-2:2013+A1:2016.

Structural performance

Lintel manufacturers produce safe working load (SWL) tables for their ranges, detailing the maximum load that a lintel can support at a given length. The quoted loads should include a safety of at least 1.6, with deflection limited to a maximum of 0.003 multiplied by the effective span. The imposed load acting on lintels arises from one or a combination of masonry load, floor load and roof load. For traditional cavity wall constructions, the floor and roof are generally supported off the inner leaf of masonry which leads to non-symmetrical loading on the lintel. This non-symmetrical loading is expressed as the load ratio which states the proportion of load on the inner leaf of masonry compared to the outer leaf. Typical load ratios are:

- 1:1 for lintels supporting masonry only

- 3:1 for lintels supporting masonry and timber floors

- 5:1 for lintels supporting masonry and concrete floors.

Thermal performance

The thermal performance of a building is calculated by taking into account heat loss through the fabric of the building itself, such as walls, roof, floor, doors and windows, and through linear thermal bridges found at junctions between different elements of the building, including window heads, jambs and cills.

Heat loss through the building fabric is expressed as a U-value and measured in W/m2K, while heat loss via linear thermal bridges is expressed as a psi (ψ) value and measured in W/mK. The total fabric heat loss is the sum of the combined fabric U-value multiplied by the total area, plus the product of the psi value of junctions and their total length.

Lintels can be a major thermal bridge in a building, and the lower their psi value, the better for overall performance. Default lintel psi values can be taken from the BRE document 1/06: Assessing the effects of thermal bridging at junctions and around openings or from accredited construction details. These are the details normally found in SAP calculators, and represent the worst-case scenario. Lintel psi values are also included in manufacturers’ typical thermal details, and they should also be able to provide more specific values.

Improved psi values can be achieved by using lintels without a base plate, and thermally broken or separate lintels. Psi values are not just affected by the lintel itself but by wall construction, insulation type and window position.

Damp-proof course

Some lintels have a built-in damp-proof course (DPC), which can remove the need for a separate one. For steel lintels to act as a DPC, they must be a minimum of 140mm deep and manufactured from austenitic stainless steel or galvanised steel with an additional 40μm (micron) powder coating.

Whether or not a separate DPC is required will be determined by the exposure zone in which the building sits. This is determined by BS 8104:1992, which divides the UK up into four zones according to exposure to wind-driven rain.

Exposure zones 1 and 2 are defined respectively as “sheltered” and “moderate” and subject to wind-driven rain of approximately less than 33litres/m2 per spell, and between 33-56l/m2 per spell. For lintels with a built-in DPC, no additional DPC is necessary in these areas.

Zones 3 and 4 are defined as severe and very severe, and subject to 56.5-100l/m2 and more than 100l/m2 per spell. These cover the west of England, and most of Wales, Scotland and Northern Ireland. A separate DPC must be used in these exposure zones to satisfy NHBC and Zurich Municipal technical requirements. Lintels without a built-in DPC require a separate DPC for all applications.

Corrosion resistance

BS EN 10346:2015 covers continuously hot-dip coated steel flat products for cold forming.

To provide the standard of corrosion resistance required by BS EN 845, lintels can be manufactured from:

- Galvanised steel with a minimum zinc coating of 600g/m2

- Galvanised steel with a minimum zinc coating of 275g/m2 plus an additional organic coating

- Austenitic stainless steel.

Austenitic stainless steel is a chrome nickel alloy. BS EN 1996, or Eurocode 6, governing the design of masonry structures implies that in certain conditions only austenitic stainless steel should be specified: - For buildings exceeding three storeys in a non-aggressive environment

- For buildings located in aggressive environments, such as coastal areas.

Fire tests

Lintels require independent fire testing or assessment in accordance with BS EN 1363-1:2012 or BS 476-21:1987. Typically, when used in conventional brick/block construction, cavity wall steel lintels may be regarded as having a fire resistance of one hour in relation to Building Regulations, or medium duration in Scotland.

LINTEL SELECTION

There are more than 10,000 lintel variations to choose from. The correct lintel specification will be determined by: the wall construction, the structural opening and the load on the lintel.

Wall construction

- Cavity wall For cavity walls, it is necessary to know the width of the outer leaf, the cavity and the inner leaf. Most lintels for cavity walls are now “open back” and depending on their specific design are suitable for standard duty through to extra heavy duty loading conditions, including direct roof loading and attic truss loads (see below).

- Timber frame Lintels for timber-frame construction are supplied with lintel restraint clips, which must be screw- or nail-fixed to the timber frame. These clips help to minimise rotation of the lintel and allow for differential movement between the timber structure and the brick facing. Pinch battens are also used to minimise rotation. Lintels should be suitably propped during construction.

- External solid wall lintels Lintels for this type of construction come in three forms:

- A single element lintel designed to carry a single leaf of brickwork

- A two-piece lintel shaped to carry the two separate leaves of a 215mm fair-faced brick wall

- A box profile with a toe for use in solid brick or block walls of 200-215mm thick.

- Internal wall Lintels for internal wall constructions come in three forms:

- Corrugated lintels offer a cost-effective solution for light duty loads

- Channel lintels are used in standard duty loads

- Box lintels are sized to suit brick or block course heights. These should be used for heavier loads and wider openings.

- Special lintels to suit semi-circular arches, apex arches, bay windows, etc. can also be designed and manufactured to order.

Structural opening width

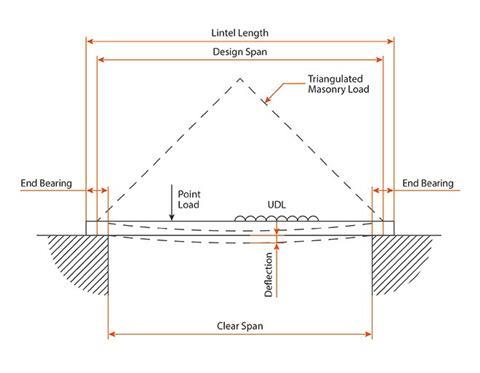

Measure the size of the open space between the walls where the door/window frame is fitted. Add a minimum of 150mm to each end.

For example, for a structural opening or clear span of 1,800mm, the minimum lintel length required will be 1,800 + 150 + 150 = 2,100mm.

What load is to be supported by the lintel?

This may include roof trusses, floor joists and masonry. Manufacturers may be able to help specifiers determine the load if they are unsure.

- Standard-duty loading conditions include: triangulated masonry loads, uniformly distributed masonry loads, uniformly distributed timber floor and roof loads

- Heavy-duty conditions include concrete floors, attic truss loads, larger span multiple truss loads

- Extra heavy-duty loads are as heavy duty, but for higher safe working loads (SWL) and longer spans.

LINTEL ACCESSORIES

A range of accessories are also available for different applications:

- Arch centres are used for the construction of segmental arches in brickwork. This is a PVCu unit for use over openings in external cavity walls, of either traditional or timber-frame construction, which provides permanent centring for brick arch construction.

- Weep vents and stop ends are used for removing water from cavities. DPC and cavity-tray installations over openings require weep vents to discharge collected water from the cavity above. NHBC standards state that weep vents must be fitted at a maximum of 450mm centres, with at least two per opening. Stop ends prevent the flow of moisture laterally.

- Soffit cladding provides extra protection, especially in coastal regions, and in situations where much of the lintel soffit is exposed. It can also improve the appearance of windows, and is particularly suitable for use with PVCu frames.

A DPC should always be used in conjunction with soffit cladding.

INSTALLATION

For successful installation, ensure that:

- Wall dimensions are correct

- The masonry overhang does not exceed 25mm

- Masonry above the lintel has cured before floor or roof loads are applied

- The lintel is not damaged

- The lintel is level along its length

- There is a nominal 150mm end bearing at each end

- The lintel is fully bedded on bricklaying mortar

- Where the lintel carries an external cavity wall, that no more than half of the safe working load is carried by the outer leaf

- In severe exposed conditions, that a separate DPC has been installed

- That point loads are not applied directly to the flanges of lintels

- For coastal areas, that the use of soffit cladding has been considered

- That window/door frames have been located so that the drip on the lintel projects forward of the frame.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 27 JANUARY 2017

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about Building CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at www.building.co.uk/cpd

1 Readers' comment