Reducing air permeability is a key principle of the Passivhaus standard. This CPD, sponsored by SMARTPLY, shows how advanced OSB panels can help to achieve this goal

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 30 MINUTES

DEADLINE: 19 DECEMBER 2016

INTRODUCTION

Passivhaus is a low-energy performance standard that can be applied to many building types, from homes and care homes to schools, hotels and supermarkets. It is intended to reduce the energy demand for space heating and cooling, while creating excellent indoor comfort levels. This is primarily achieved by adopting a “fabric first” approach to the design, with very high levels of airtightness, increased levels of insulation and reduced thermal bridging, and the use of mechanical ventilation with heat recovery.

Airtightness is an essential part of creating an energy-efficient building and is a Building Regulations requirement. According to NHBC, home energy use is responsible for approximately 27% of the UK’s carbon dioxide emissions. A 2002 report from the BRE found that air leakage can be responsible for up to 40% of heat loss from buildings. Buildings designed to Passivhaus standard achieve a 75% reduction in space heating requirements compared to standard practice for new buildings in the UK. The Passivhaus standard therefore provides a robust method to help the construction industry meet the government target of an 80% reduction in carbon emissions by 2050.

ACHIEVING AIRTIGHTNESS TO PASSIVHAUS

The key principle for achieving airtightness is to create a single, continuous and robust airtight layer which surrounds the heated volume of the building. It is typically located on the warm side of the insulation, therefore also fulfilling the requirements of the vapour control layer.

In order to achieve Passivhaus certification, a building must achieve airtightness of less than or equal to 0.6 air changes per hour, under test conditions. This is expressed as n50 ≤0.6h-1 @ 50Pa, where n50 is defined as the number of air changes per hour at a reference pressure differential of 50Pa. The result is calculated using the building’s internal air volume (m3), rather than its envelope area (m2), so the units are expressed as m3/m3.h, simplified to h-1. This must be the average of pressurisation and depressurisation, which is carried out using a blower door test. Meeting this level of airtightness is challenging but possible with a clear design strategy, with the final result also being sensitive to the quality of workmanship on site.

Current Building Regulations require air permeability at 50Pa to be 7-10m3/h/m2, depending on whether a project is in England, Wales, Scotland or Northern Ireland, so the Passivhaus limit is approximately five times less than the maximum permitted. It is not possible to make a standardised conversion between air permeability values and n50 air change rate values because there is no direct relationship, and each uses different testing and measurement protocols. But to put this in context, the airtightness level of n50 ≤0.6 h-1 @ 50Pa is roughly equivalent to a hole in the envelope of the building that is less than the size of a 5p piece for every 5m². In comparison, a building that complies with the limiting figure for airtightness in the Building Regulations Part L (2013) (Section 6 of the Building Standards, Scotland and Building Regulations Part F, Northern Ireland) would have a hole the size of a 20p piece for every 1m² of envelope.

AIRTIGHT PRODUCTS

Traditionally plastic air and vapour control layer (AVCL) membranes have been used to achieve airtightness, although surprisingly there is no recognised industry standard or test method. The degree of vapour diffusion depends on the material composition, and the success of such systems is dependent on detailing, installation and workmanship on site.

One alternative is to use certified air and vapour-tight oriented strand board (OSB). Standard OSB (and other types of wood panels such as plywood, particleboard and MDF) are not suitable as an air and vapour tight layer, as their air and vapour permeability is inconsistent and can vary greatly between production cycles and manufacturing sites. Air and vapour-tight OSB is a newer technology: a structural OSB panel which also has integrated vapour control and air-barrier properties, developed for the timber frame market.

The key British and European standards governing the specification and use of OSB panels in construction are BS EN 300 and BS EN 13986.

BS EN 300 includes a classification system that defines four grades of OSB in terms of their mechanical performance and relative resistance to moisture. These are:

- OSB1: General purpose boards and boards for interior fitments (including furniture) for use in dry conditions

- OSB2: Load-bearing boards for use in dry conditions

- OSB3: Load-bearing boards for use in humid conditions

- OSB4: Heavy-duty load-bearing boards for use in humid conditions.

OSB3 is suitable for a range of internal and protected external uses, including roofing, sarking, flooring, site hoarding and sheathing for external walls, party walls, internal walls and partitions, spandrel (gable) panels, warm walls, reverse walls and structural insulated panels.

Products such as SMARTPLY’s PROPASSIV OSB panels (classified as OSB3) offer an alternative to specialist air and vapour control layer membranes. The panels are air and vapour tight, guaranteeing airtightness and preventing interstitial condensation within the timber frame structure without the need for a separate membrane.

OSB is made by forming strands of wood from softwoods, such as spruce and pine, bound with a moisture-resistant, formaldehyde-free synthetic resin into three layers (bottom surface, core and top surface), and pressing under high temperature and pressure to form a rigid and dimensionally stable wood panel. The wood strands are alternately oriented through 90°, so that the core layer is at right angles to the outer layers. Orientation of the strands in this way distributes the strength, stiffness and spanning capacity of the finished OSB panels, which are approximately twice as strong in the length (major axis) as in the width (minor axis).

To overcome the variable air permeability in traditional OSB, care is taken during the manufacturing process to eliminate density variations and air gaps. SMARTPLY’s PROPASSIV OSB panels have been certified by the Passive House Institute (PHI) to achieve the highest level of air permeability of 0.01m3 /(m2h) (PHI Class A).

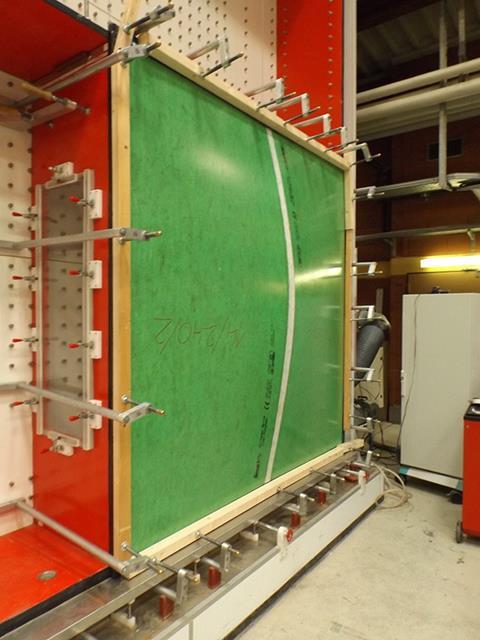

To overcome inconsistent vapour permeability in OSB, the inside face of the panels are coated with a water vapour-resistant polymer coating. This provides a consistently high water vapour resistance across the surface of the panel, and its smoothness also ensures strong adhesion of airtight tape at panel joints. Tests of SMARTPLY’s PROPASSIV panels conducted at the Fraunhofer Institute of Building Physics found that the coated surface was ideal for tape adhesion and the airtightness of the engineered OSB allowed it to withstand pressures of +/-2000Pa. When SMARTPLY PROPASSIV is installed with airtight tapes, it has achieved n50 values as low as 0.09 air changes per hour.

VAPOUR CONTROL IN TIMBER-FRAME BUILDINGS

For timber-frame buildings in cool temperate climates, a vapour control layer is required on the warm side (inside) of thermal insulation to prevent excess water vapour entering the building fabric via diffusion. Warm air holds greater water vapour than cold air, and therefore has a higher vapour pressure. Vapour diffusion transfer occurs when the warm, moist air inside a building migrates (diffuses) under high vapour pressure through the building fabric to the low vapour pressure cold air (outside). If this vapour transfer is uncontrolled, condensation within the building fabric (interstitial condensation) can occur as the moist air cools and the vapour condenses on the cold side of the assembly. The purpose of the vapour control layer is therefore to limit the amount of water vapour entering the building fabric.

Air and vapour-tight OSB panels can also help to prevent summer condensation by acting as a humidity buffer. Materials made from cellulose fibres are hygroscopic and therefore can absorb and release small amounts of water vapour from the surrounding environment. In the limited number of cases of reverse vapour diffusion, OSB panels can help to prevent condensation within a structure. This is where moisture from the outer leaf of a building envelope is heated by summer sun and permeates through to the cooler inner layers, posing a potential condensation risk if not controlled or designed out.

Research into the suitability of OSB panels as the air and vapour barrier in timber-frame structures found that the quality of the installation was just as important as the intrinsic vapour resistance of the panels. This was quantified by the Fraunhofer Institute of Building Physics in 1989, when investigating the effect of a 1mm tear in the plastic vapour control layer. It was found that the gap increased the vapour transmission from 0.5g/m2 to 800g/m2 (almost two pints in 24 hours) as vapour was transferred by convection and not by diffusion – convection was found to carry 1600 times more moisture into the structure. Therefore, it is critical for the long-term performance of well-insulated buildings that both airtightness and vapour tightness are considered in tandem at the design stage, and that suitable, fit-for-purpose and certified products are chosen.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 30 MINUTES

DEADLINE: 16 DECEMBER 2016

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about Building CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at www.building.co.uk/cpd

No comments yet