Pupils at Kingsdale comprehensive have a bright future thanks to the translucent etfe dome that’s been used to transform the 1950s building.

Five years ago Kingsdale was a failing inner city school. The 1100 pupil mixed comprehensive in the south London borough of Southwark had just been placed on ‘special measures’ by Ofsted, absenteeism among pupils was rife and morale was in short supply. The peeling paint and broken windows of the down at heel school buildings betrayed nearly five decades of wear and tear.

Today the contrast is tangible. The arrival of head teacher Steven Morrison in 1998 signalled the beginning of a turnaround and together with the teaching team, pupils and parents Morrison set about revitalising the school. Academic results have already been dramatically improved and the number of pupils achieving five or more GCSEs at A-C grade has risen from 15% in 1999 to over 41%. Part and parcel of this transformation has been the imaginative renovation of the school buildings, the first phase of which is now complete.

The project has been delivered as part of the Architecture Foundation’s School Works initiative, which sought to show how the design of school buildings could have a major impact on teaching and raising educational achievement. In 1999, with the backing of the Department for Education and Skills (DfES), Kingsdale was selected to put these ideas into practice and together a brief was drawn up for a RIBA competition. School Works argued that building design should not be imposed on the school by the Local Education Authority or planners, rather that it should come from the bottom. The fledgling practice of de Rijke Marsh Morgan (dRMM) won the architectural competition, impressing judges not just with its early design proposals but also with its proposed consultation process and plans to engage the school community. Overall the consultation process took around nine months and along with the design team included the involvement of an educational psychologist, an education researcher and performing artist. Significant contributions from the pupils included complaints about the state of the toilets as well as the classrooms being too hot or too cold. The school’s poor existing building fabric also contributed to many of the issues raised.

Environmental engineers Fulcrum Consulting, who had been brought in by dRMM to help work up the scheme at competition stage, was appointed to help develop the emerging design. Several schemes were put forward ranging in cost between £5 million and £14 million and although the school was on ‘special measures’, which prevented it accessing capital funds, the DfES finally agreed to provide funding of £9 million.

The courtyard

Belying its reputation Kingsdale is located off a leafy suburban road on a large site next door to the affluent Dulwich College prep school. The building is typical of many schools built in the 50s. Constructed as a rectangle around a central courtyard it had a racetrack corridor lined on either side by classrooms. This was one of the dislikes pupils had raised in the consultation, as its narrowness hampered circulation and was deemed by staff as the cause of disruptive behaviour – a cctv system installed to monitor pupil’s behaviour reinforced the lack of trust between staff and pupils.

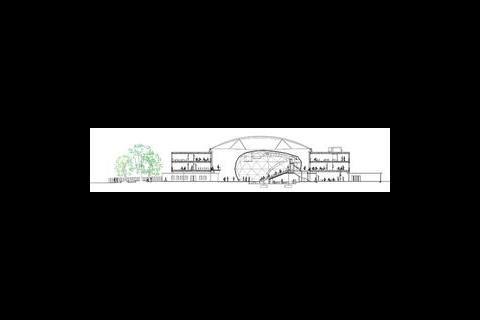

Dividing the courtyard was a single storey school hall which was too small for assemblies, while the two spaces created on either side of it were used solely as rat runs for pupils dashing from one side of the school to the other. James Hepburn of Fulcrum says enclosing the courtyard was the obvious thing to do. “It was a redundant space as it was and the school wanted somewhere that it could get together for assemblies as well as a performance space and a dining area.” The challenge of roofing-over the courtyard was put into perspective by its size; it measured 80 m in length and spanned almost 40 m.

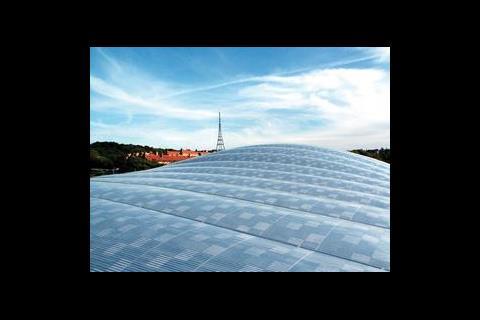

Initial proposals included a solid, folded plywood roof with a series of north lights, although this was soon dismissed on the basis that not enough daylight could be brought into the space and the surrounding classrooms. Similarly the high cost and the need for additional structural supports ruled out a glass roof. The design team began to explore the possibility of using ethyl tetra fluoro ethylene (etfe). This offered a number of advantages: excellent transmittance and a U-value of 2·0 W/m2K. It also had a low mass (25 kg/m2), allowing the entire structure to sit on the school’s existing roof and exploit the spare capacity in the building’s steel frame with only the addition of wind bracing members in the new courtyard. DRMM was quick to embrace the etfe option, and the school, following initial concerns about the maintenance of the blower units essential for inflating the etfe cushions, also bought into the idea. “It was within the budget and it did everything we wanted,” says Hepburn. “It was then that we had to convince people that they needed to go for the variable skin option.”

The atrium is classed as an indoor/outdoor space, however the school wanted to be able to use it during lunchtimes throughout the entire year. Fulcrum wanted heat gain in the winter but not in the summer and using Tas undertook dynamic modelling to establish what temperatures could be expected between 12 and 2 in the afternoon. These initial calculations for the clear etfe produced some frightening results, suggesting temperatures in the space reaching up to 45°C in the summer months. A grey (tinted) version of etfe would have worked to a degree says Hepburn, “But to make it habitable in the summer we would have needed to opt for a very dark version. That wouldn’t let much light in and we needed to take into account the daylight into the classrooms facing into the courtyard. Furthermore it wouldn’t have been warm in the winter, it wouldn’t have given them the space they wanted.”

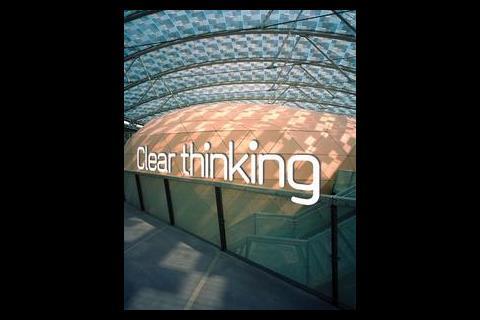

Studies were carried out on a variable skin version. Unlike conventional etfe this can be controlled to vary the amount of daylight and solar gains into the space. Each ‘cushion’ is constructed of three layers of etfe, the top two of which are screen printed with silver grey stripes. By inflating or deflating the lower chamber the patterns can be made to either mesh or unmesh, varying the amount of light coming through. An optimum transmission of between 5% and 50% was established for which Fulcrum calculated that during 75% of the school year the space will be above 14°C at lunchtime, while exceeding 28°C in the summer only for very few hours.

Within the courtyard the design team was looking to achieve 500 lux on an overcast winters day. “We wanted to have it so that there is as much light in the main central space as possible,” says Henrietta Lynch, lighting engineer with Fulcrum. “We were also looking to maximise daylight into the inward facing classrooms, and we were aiming to achieve these levels when the roof was ‘shut’, with only 5% admittance.” The overall effect is a bright open space, made more appealing by the shadows created by the geometric patterns of the variable skin which are projected across the surfaces of the courtyard. Clerestory windows running below the perimeter of the roof add to the open feel, giving the impression that the roof stands clear of the existing structure. These are again manufactured from triple skin etfe, but unlike the roof are completely clear.

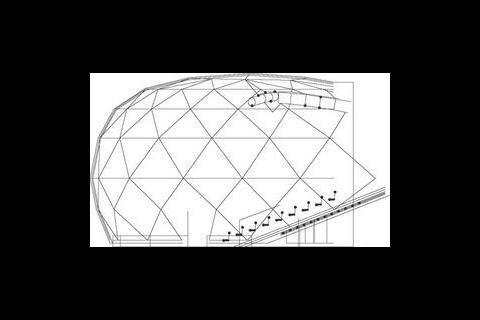

Covering an area of around 3200 m2, the roof lays claim to the largest variable skin etfe installation in the UK. Its control is driven by the ventilation strategy (see below) but to keep it simple the roof is divided into three zones. Because there is no intermediate stage – the roof is either at 5% light transmission or 50% – to get an incremental change each third ‘cushion’ is linked via the controller to a blower box mounted on the school’s existing flat roof. In total the variable skin option has come in at £1.8 million, still well below the price of the glass and timber solutions initially considered.

The courtyard space is naturally ventilated and this also feeds the surrounding single sided naturally ventilated classrooms, providing a buffer zone to the rooms in winter. Opportunities to introduce low-level vents were limited by the surrounding school building. This has been overcome by installing a 20 m run of horizontal, motorised dampers above the main entrance on the building’s west side. These are neatly integrated between the steel trusses supporting the first floor and provide a route for outside air to enter the entrance lobby. This is supplemented by a similar run of vertical dampers built into the outside wall of the administration block. For security reasons a glass screen with motorised doors separates the entrance lobby from the courtyard, however this falls short of the ceiling by around 800 mm to provide the air path into the courtyard. In summer months a large sliding steel door, adjacent to the main entrance can be pulled back at the discretion of the staff and acts as a very effective means of boosting airflow.

Stale air in the enclosed courtyard is vented at high level through a total of six 12 m by 2·5 m etfe flaps incorporated into the steel trusses at either end of the new roof. These are driven open by electronically actuated pistons depending on conditions and, to make integration easier, were designed and installed as part of the roof package by Vector. Ventilation is controlled on temperature, with sensors at low, mid and high level in the space as well as outdoors. “We try and control the temperature in the space using ventilation first because we want to maximise the daylight,” says Hepburn. “If the ventilation isn’t going to do it we then start ‘shutting’ the roof down.”

Recordings taken throughout May, June and July of this year show low level temperatures not exceeding 30°C, and while high level temperatures are predictably above these they haven’t risen beyond 35°C. Overheating was always experienced on the second floor classrooms facing south and west. Inevitably it still is, given the lightweight glass curtain walling and single glazing construction. However those looking into the courtyard on the east side do at least now get some benefit from the shading provided from the roof. The scope of the next phase of work will include looking at providing further solar shading to the external facades of these rooms as well as ventilation, either mechanical or possibly natural using a roof mounted wind driven device.

The pod

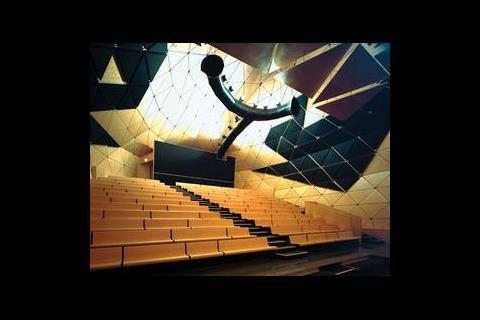

Also part of the first phase of works is a 400-seat auditorium. The egg-shaped pod sits near the centre of the atrium and takes the form of a timber space frame clad internally and externally in triangular birch-faced plywood panels – this needed to comply with Part L of the Buildings Regs given that it stands in an indoor/outdoor environment. Inside, a displacement ventilation system serves the windowless space. Fresh air is drawn from the atrium via an air handling unit located in the base of the structure and is delivered via the large plenum created beneath the raked seating through narrow slots formed where the precast concrete floor slabs abut. A dx coil in the ahu can be used to cool the incoming air to its 18°C delivery temperature with heat recovery provided by a thermal wheel.

Not many buildings can boast ductwork designed by an international artist, yet when the school received a grant from the Royal Society of Arts to have a piece of artwork commissioned the decision was made to double it up as the air extract. Dutch group Atelier Van Lieshout designed the prominent sculpture that cantilevers from the rear wall of the auditorium. Hepburn was up for the idea but a bit apprehensive, “As it needed to work as a duct we wrote out quite a detailed spec trying to say it needed to be this diameter, smooth, non fibrous. We saw a number of sketches and the structural engineers went out to Holland to check it out.” Dubbed the ‘cannon’, the sheet steel structure was trucked over from Holland in three sections and installed by the main contractor on site. Ensuring enough free area was an initial concern and a series of apertures were created along its spine, despite this worries that it would whistle because of the rough joints and holes have proved unfounded.

Temperature sensors control conditions within the auditorium. The route of the extract air depends on the temperature of the air in the auditorium and the air in the courtyard. In the winter for example the warm air is vented to the courtyard while in the summer it can be routed via motorised dampers to the outside.

Lighting for the auditorium is mounted on the extract duct and, at under £10 000, proved to be a low cost solution. Although fitting the external asymmetric floodlights to the sculpture raised eyebrows with the electrical contractor, the result works well and avoided the complications of trying to suspend fittings from the narrow gaps between the panelling and the need for ugly surface mounted conduits.

Acoustics were also an issue, particularly given the auditorium’s less than ideal shape and the hard surfaces. Acoustic specialists Fleming & Barron modelled the space resulting in diffusers being mounted above the stage area and Ecophon acoustic panels on the walls to absorb and prevent reflections. One particular weak point that came out of the study was the junction at which the triangular wood panels meet. Here a 5 kg/m² barrier mat is installed to reduce sound transmission.

Future phases

The new atrium and auditorium sit at the heart of the refurbishment but are by no means the extent of the work. A new IT suite on the second floor was an ‘early win’ phase carried out in the summer of 2001. Further work under phase one was tendered in spring 2002, and took in the remodelling of the majority of the first floor classrooms, as well as new changing rooms and toilets – one of the priorities stemming from the initial consultation with pupils – and enabling works for the courtyard.

All the works have been tightly designed around a budget and Hepburn says they worked closely with the quantity surveyor from day one. “As full designs were not complete, provisional sums were agreed with the qs for each phase and a full schedule of rates was obtained with the tender returns. The design of the m&e services were then carried out once the architectural plans had been signed off by the school.”

There have been many tricky problems to overcome especially when dealing with the existing building services and working around a fully functioning school. Southwark Council required the use of a GC Works 1 contract, while School Works pushed for some kind of partnering arrangement. A partnering overlay was added to the GC Works contract, which says Hepburn started the project going in the right direction: “Nobody scurries away into a corner to hide behind their formal contract.”

Prioritising the works also introduced the need to consider future phases. The boilers for instance would ideally have been replaced at the beginning of the project but this was ruled out because of the lack of funds. Instead, as well as installing the new lighting and dado trunking for IT and power during the class refurbs, the hot water pipework was renewed back to the risers ready for a time when funds might become available.

Phase 1 was completed in spring this year and phase 2 is now underway, which includes refurbishing the majority of the other classrooms and hopefully the construction of new satellite blocks for the music and sports department, ambitions that were dropped from the original scheme.

Following from their experience at Kingsdale, many of the key players collaborated in the Building Schools for the Future compendium of exemplar designs. The scheme put forward for a rural secondary school picks up on the etfe solution used to transform the courtyard. “The head of the partner school really just wanted a big space,” says Hepburn. “He wanted a building without doors and was totally rethinking the conventional school model. It all fell quite nicely into place as we knew how to create a big space very efficiently”. The design includes a massive variable skin etfe dome used to create a large indoor/outdoor space in which a variety of modular classrooms can be configured. “All we need to do now is build one,” adds Hepburn.

Kingsdale School, Alleyn Park, Dulwich SE21 8SQ

Mechanical suppliers

Auditorium ahu

PM luft

Louvres, grilles and diffusers Waterloo

Ductwork dampers BSB

Syphonic rainwater drainage Fullflow

Ductwork KJ Engineering

Supply/extract fans Vent Axia

DX systems Space Cooling

Insulation Hervecourt

Lift Kone

Radiators Stelrad

Attenuators Caice Acoustics

Valves Hattersley

Electrical suppliers

Cable management Cableduct

Electrical distribution Eaton Electrical

Accessories Ashley

Fire alarm ADT

Luminaires Encapsulite, RIDI, Commercial Lighting Systems

Public address ADT

Auditorium and library

Floor area 610 m2

Occupancy 400

Ventilation 8 litres/s/person (with thermal wheel heat recovery)

External design conditions -1°C /Sat

Summer (a/c) 28°Cdb, 20°Cwb

Winter 18°C

U-Values Pod walls 0·35 W/m2K; Floor 0·25W/m2K; Glazing 2·0 W/m2K

Covered courtyard

Floor area (including walkways and entrance) 3500 m2

Ventilation Naturally ventilated

Noise levels NR 30

External design conditions -1°C /Sat

Summer no control 30°C (target)

Winter 14°C at lunchtime (target)

U-values (roof) 2·0 W/m2k

Source

Building Sustainable Design

Credits

Client

Southwark Council

Project manager

Southwark Building Design Services

Architect

de Rijke Marsh Morgan (dRMM)

Structural engineers

Michael Hadi Associates

QS

Appleyard and Trew

Main contractor

Try Accord

Mechanical subcontractor

Briman DBS

Electrical subcontractor

McMillan & Co

No comments yet