Chilled beams – passive

So what are chilled beams, how do they work, and to what applications are they best suited? The simplest of beams is the passive beam, which is little more than an aluminium finned copper coil mounted in a galvanised metal casing. The top and bottom of the casing are open to allow the downward flow of cooled air following contact with the coil. The extent of the downflow is determined by the difference between the mean water temperature in the coil and the room air temperature and the depth of the beam casing. To facilitate this downdraught the beam must be mounted 100 mm to 150 mm below the soffit, depending on the beam width.

The cooling output from passive beams is limited by the danger of condensation forming on the coil and the danger of excessively high room velocities directly below the beam. Typically chilled water flow temperatures should not be lower than 14°C to avoid condensation. Tests show that outputs of greater than 200 W per linear metre could result in occupant discomfort due to downdraught from the beam.

Passive beams are best suited to perimeter or corridor locations where outputs of up to 500 W per linear metre could be achieved, depending upon the upper limit of room temperature. Passive chilled beams provide static cooling only and therefore a separate air supply system is needed to satisfy the minimum fresh air requirement. Some cooling contribution can be realised via the air supply and this is maximised using high-level turbulent mixing systems.

Passive beams can be mounted within the void behind a false ceiling, providing that a high free area section of ceiling is provided directly below the beam to accommodate the downflow of cool air. An equal area of high free area ceiling must also be provided adjacent to the beam to allow the upflow of warm replacement air.

Typically, the cost of a passive beam system would be £140 m2 to £200 m2 with a cooling capability (assuming comfort conditions) of around 80 W/m2 to 90 W/m2.

Chilled beams – active

An active chilled beam uses primary supply fresh air fed into the beam at high velocity to induce room air across the cooling coil. This air flows upwards across the coil, is induced and mixed with the primary air and is distributed via geometrical slot outlets to the room.

Two immediate advantages are apparent, firstly there is no requirement for an air gap above the beams so they can be mounted directly below the ceiling slab and secondly the distribution facility provided by the slots removes the danger of excessive downflow velocities.

The advantages of all static cooling systems are that the majority of required cooling is provided by the chilled water, which is far more efficiently circulated than the equivalent volume of air, not to mention the reduction in ceiling and riser space. However, active beams are driven by the primary air and, assuming occupation densities of one person per 10 m2 and an average beam spacing of 3 m, room sensible loads of greater than 70 W/m2 to 80 W/m2 would require more primary air than the minimum required for fresh air, and so the size of the primary air plant would need to increase as the beam load increases.

The cost of an active beam system would be in the region of £160/m2 to £210/m2 and the sensible load capacity would be up to 160 W/m2 assuming 20 litres/s/linear metre primary air. The active beam can also be used for heating; the single coil is laced with two separate circuits to avoid mixing of heating and chilled water. Using flow temperatures of 35°C to 40°C, heating outputs of up to 96 W/m2 can be achieved. The cost of a good quality four pipe fan coil system would be up to £200/m2. One major advantage of chilled beams installations is the low maintenance requirement; no fans or other moving parts and at 4 mm coil fin spacings there is no requirement to filter the induced room air before it passes over the cooling coil as there is little danger of dust build up.

As with passive beams, active beams can be exposed or recessed behind a false ceiling; the exposed option may be fitted with decorative side panels to hide chilled water and heating pipe work which may also be used to mount light fittings, sprinkler heads, detectors, pa systems for example. The control of chilled beams is normally via on/off control valves in the chilled water return connection, but for applications requiring high primary air volumes, more effective and responsive control can be achieved by varying the primary air volume.

Chilled ceilings – radiant

Chilled ceilings have been with us for a number of years. The most commonly used is the radiant chilled ceiling, comprising of a copper serpentine fitted to the back of a closed metal ceiling tile. The copper pipe exchanges heat with the ceiling tile via an aluminium heat transfer plate which is fixed to the rear of the tile. An insulating mat is fitted to the rear of the tile to minimise cooling in the direction of the ceiling void. Radiant chilled ceilings can also be used with gypsum board ceilings, and in both cases the heat transfer has a high radiant element, with realistic outputs of 50 W/m2 to 60 W/m2 (floor area) based on chilled water flow and return temperatures of 16°C and 18°C and a room temperature of 24°C. This also assumes an 80% active area.

Like passive chilled beams, these systems need a separate air supply system to provide fresh air. Any type of air system can be used, but ceiling mounted turbulent flow systems offer the greater contribution to the cooling ability of the systems and will improve the output from the chilled ceilings. The contribution of low level systems will be limited by their higher supply air temperatures. A radiant chilled ceiling system would cost between £150 m2 and £210 m2.

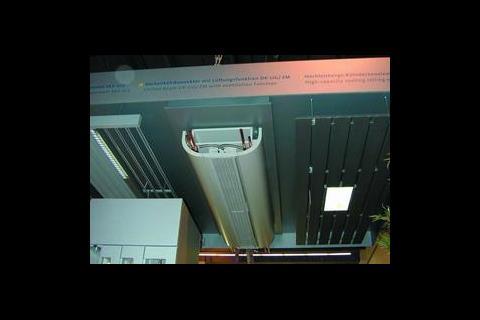

Chilled ceilings – convection

High capacity convection panels are used extensively throughout Europe, and for very good reasons. Due to the more convective nature of their operation, they are more closely related to passive beams but with a number of significant advantages. Like passive beams they can be recessed behind an open false ceiling (free area >23%) or exposed below the slab of only 50 mm. However, the panels themselves are only 85 mm deep and require a circulation gap below the slab of only 50 mm. The chilled water flow temperature can be slightly lower than for radiant panels, as any misting due to condensation re-evaporates as room air passes across the fins. Sensible cooling output of up to 160 W/m2 can be realised with room temperatures of 24°C which, assuming 80% cooling coverage, would give a net figure of 128 W/m2 floor area.

Unlike the passive beam, a downdraught below the beam is minimal as the cooling source is spread over a greater area allowing mixing with room air as cool air descends. The chilled panels are suspended directly below the ceiling slab and are independent of ceiling installation, therefore separating mechanical and ceiling installations. As for the passive beams and radiant ceilings, a separate fresh air supply is required and again a high level turbulent flow system would be the best option.

The choice is yours

All the above systems have the advantage of high efficiency, low maintenance, low noise and the cost range of each is not dissimilar. The choice of radiant metal tile ceilings or exposed chilled beams with decorative wings would probably be driven by architectural preference or fashion. Most modern offices, having internal sensible loads exceeding 100 W/m2, would tend to suit active chilled beams, but there is a strong case for the high capacity convective panels due to their flexibility and ability to offset heat gain, supported by their widespread use in Europe. The signs are that this could be our next fashion statement.

Source

Building Sustainable Design

Postscript

Ian Lees is sales director for Krantz Systems.

No comments yet