Like its Finnish and French twins, Hinkley Point C has suffered from cost overuns and delays. What are the team doing to claw back the losses and what does this mean for Sizewell C?

Nothing on the drive from Taunton to Hinkley Point C hints at the scale of the project at the destination. The journey is along picturesque minor roads, through woods and up and down steep-sided, intimate valleys before the terrain flattens out to reveal Europe’s largest construction site.

The huge location, which is deliberately situated miles away from major population centres, sprawls across a flat plain next to the Bristol Channel on the Somerset coast. Everything about this project is supersized.

There are 58 cranes on this job, one of which is Big Carl, the world’s largest land-based crane. Powered by 12 engines and rolling on 96 wheels, this monster can lift 5,000 tonnes and needs dedicated tracks to move it to the different parts of the nuclear island, where the reactors are being built.

A dedicated bus company was set up to avoid thousands of workers clogging up the lanes with traffic. It brings up to 11,000 of them from around the area and home again on a fleet of 176 buses. This includes a route to transport people around the 176-hectare site. The site even has a doctor’s surgery, a fire service and police station.

The civil engineering works are well advanced, with one of the two reactors close to fit-out and construction on the second coming along. Works elsewhere are progressing with the project about to move from the civil engineering phase to the complex mechanical, electrical and heating fit-out stage (see box).

Getting to this point has been long, slow and expensive. Hinkley Point C is the first nuclear reactor to be built since Sizewell B was completed in 1995. Called the European pressurised water reactor (EPR), Hinkley Point C is the third example to be built in Europe. The first was built at Olkiluoto in Finland and the second at Flamanville in France.

Each of these projects has gone massively over budget and taken much longer to build than envisaged (see box). The latest estimates suggest that Hinkley Point will cost as much as £34bn, nearly double the original budget of £18bn.

Originally scheduled to complete in 2025, the plant could come online as late as 2031. Why is Hinkley proving so expensive to build, despite the lessons from two earlier projects? And what are the cost and programme implications – and therefore the likelihood of it going ahead – for the proposed Sizewell C and beyond?

There are many reasons for the cost increases and delays. These include the impact of the pandemic, which has delayed construction by 15 months, inflation and the challenge of finding people with the skills to meet the exacting standards demanded by nuclear construction. Different nuclear regulatory regimes across Europe are a big reason why the third EPR reactor is still costing more and is taking longer to build than originally envisaged.

“We had to substantially adapt the EPR design to satisfy British regulations, requiring 7,000 changes, adding 35% more steel and 25% more concrete,” explains Simon Parsons, EDF’s delivery director for the nuclear island.

According to Parsons, the French regulatory approach is very prescriptive, whereas in the UK it is up to EDF to prove that its design meets UK requirements. The UK is more focused on the consequences of failure than in Europe.

The main components inside the reactor building such as the reactor pressure vessel and steam generators are made to the same design by the same manufacturers but are subject to a UK specific safety regime. “We’ve been asked to do more FMEA (failure mode and effects analysis), material analysis and fracture toughness testing of welds over a piece of equipment,” Parsons says.

The safety-first regime means that Hinkley Point has higher specification chilled water and fire fighting systems and greater segregation of components. There is a requirement for a third hard-wired, non-computerised instrumentation and control system. This was very expensive to design, develop and test before it could be approved for use.

The four safeguard buildings, each of which can maintain cooling of the reactor core in the event of a power failure, have two additional floors of HVAC compared to Flamanville. “All those changes which ensure that we can meet the UK regulators’ requirements ultimately turns into more concrete, more cables and more holes in walls,” Parsons says.

Progress at Hinkley Point

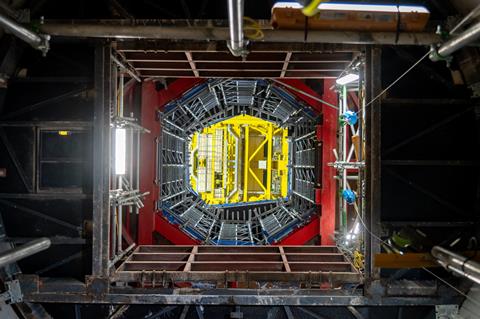

The heart of the site is the nuclear island and includes two reactors, the steam generators and pumps produce the steam for generating electricity. It also includes back-up systems including diesel generators to ensure the reactor can continue operating safely at all times.

Reactor one is the more advanced, with the inner and outer concrete containment walls and the inner steel liner and its 245 tonne, 47m diameter capping dome craned in last year. The reactor pressure vessel will be fed through a large equipment hatch and installed in October. This will be followed by four steam generators which turn heat from the reactor into steam ready for the turbine.

Reactor two is less advanced. The last section of the inner steel liner which sits inside the inner and outer concrete containment walls to withstand risks including aircraft impact, earthquakes and tidal waves, will be craned in later this year. Next up will be the installation of the reactor pool, which houses the reactor and the 750 tonne polar crane which will be used to finish construction and for refuelling and maintenance during operation.

The huge steel capping dome sits some distance away but within reach of Big Carl. It will be craned into position next year.

Steam from the reactor building will be supplied to the turbine hall which sits behind each reactor. Each 50m-high building will house an Arabelle, the world’s largest turbine capable of producing up to 1,780MW which gives Hinkley Point C a total output of over 3.2GW.

Turbine hall one is the more advanced, with the cladding being installed on the completed frame and the 300-tonne gantry crane which will be used to install the turbine and for subsequent maintenance already in place. The frame of the second hall is at a relatively early stage of construction.

The control room for reactor one sits between it and the turbine hall and is being fitted out. The trainee controllers are using a simulator that replicates the layout of the control room to learn how to operate the power station.

The electrical building which provides power to pumps, valves and other equipment is being fitted out with miles of power cables. Work is also progressing on the fuel building which houses spent fuel before being taken offsite.

Work is well advanced on reactor one’s pump house, the scheme’s largest buildings. These are barely visible as they are largely underground.

Each pump house is connected to a 6m, 3.5km-long tunnel which brings cool water from the Bristol Channel to condense the steam used to generate electricity back into water.

Both pump houses share a single 1.8km long outflow tunnel. One of the most difficult jobs is connecting the six in and outflow shafts driven through the seabed connecting the underground tunnels to the sea.

The second reactor was particularly delayed by the pandemic meaning that the original, 12-month gap between the two reactors starting operation widened, but the efficiency gains made on the second reactor construction will help to bring it back on schedule.

Materials and site processes are subjected to layer upon layer of checks, which are streamlined by using a 3D model. The model can be used to order materials, check progress on site and see which tasks have been performed by specific workers.

The design approved by the Office of Nuclear Regulation and Environment Agency, a process called the generic design assessment, is turned into a detail design by EDF and ultimately finds its way onto tablets used by site workers. The model makes it easy to track the source of materials as the regulator needs to be able to verify this.

The concrete steelwork is a good example of how this works. Standard rebar is supplied by a firm in Wales. This is subject to random metallurgical and load testing. Workers onsite can pull up a view of the work from the model. For reinforced concrete, this includes the rebar, the items to be embedded in the finished structure and the concrete.

Workers can select an individual piece of rebar to see its length, diameter and shape. This is coloured grey on the model before installation; the colour changes to yellow during installation and blue once completed and ready for sign-off. A view of the finished job is created and goes into the construction records, which can be pulled up at any point in the future.

Work is scrutinised by several layers of inspectors. The digital tools and sign-off process helps to ensure that the Bylor workers – the joint venture between Bouguyes and Laing O’Rourke who are responsible for the civil engineering work – build what has been designed.

EDF has a dedicated team of inspectors who check a proportion of the completed work with a particular focus on steel fixing. Layered over this is a team working for the Office of Nuclear Regulation.

“They are quite a small team and will go and test various things from construction to fire safety to temporary works, the sensitive parts of the building,” Parsons explains. The work is given a rating, and any areas of concern raised at regular meetings with the regulator.

The digital data will be used for building operation, maintenance and – in 60 years after the plant starts operating – decommissioning. The data has a second important function: it will be used to build Sizewell C assuming funding is confirmed by the new government. Crucially for the future of UK nuclear, this will incorporate the lessons learnt from the construction of each reactor.

Parsons says the second reactor is being built 20% more quickly than the first one. “The challenges on the first unit are because this is the first for 30 years,” he says. “We are taking that learning from building the first unit to unit two. And we have people from Sizewell embedded in our team.”

The team refer to Sizewell as if it were the same project and refer to its two reactors as units three and four. Parsons says he expects that Sizewell will be built between 20% and 30% faster than the second Hinkley reactor.

Will Hinkley Point and Sizewell provide value for money?

The last government committed itself to new-build nuclear as it believes nuclear is the only form of reliable, low carbon electricity generation which has been proven at scale. The new Labour administration remains committed to the sector and has backed Sizewell C and the development of small modular reactors.

Hinkley Point and Sizewell will produce 14% of the UK’s electricity, the same as generated in 2022. This is considerably less than during nuclear’s 1990s heyday when it generated 24.5% of the UK’s electricity.

When Sizewell and Hinkley Point C start generating power, the only operational nuclear power station will be Sizewell B, which means nuclear’s total contribution to UK electricity generation will be 17%.

The argument against nuclear is the cost, with critics saying it is poor value for money compared with renewables. All three EPR nuclear power stations built in Europe have suffered from serious cost overruns and delays.

Olkiluoto was supposed to start operating in 2010 but took 18 years to build, only starting operation last year. It cost €11bn, nearly three times the original fixed price of €3bn. Flamanville has taken 16 years to build and is due to come online imminently, 12 years later than planned. It cost more than Olkiluoto at an estimated €13.2bn despite starting out with a similar budget.

Hinkley Point C got the green light in 2016 with an estimated £18bn build cost and completion by 2027. The most recent estimates put costs as high as £34bn at 2015 prices, £46bn in today’s money. The poor budgetary track record of the EPR begs the question, is new nuclear good value for money?

Hinkley Point was originally a privately financed joint venture between EDF and China General Nuclear with EDF owning two-thirds and CGN the remaining third. The station was to be financed using the Contracts for Difference mechanism which is used to support forms of electricity generation which can’t compete with gas.

This government guarantees a minimum payment for the electricity, the so-called strike price. In 2012 a strike price of £93.50mWhr was agreed for Hinkley Point C at a time when electricity cost £40mWhr, provoking criticism that nuclear was too expensive. The strike price is inflation linked meaning it is worth approximately £139 at 2023 prices.

The government revised the strike prices for renewable generation in December 2023, the strike price for offshore wind is £73 and PV £61 so nuclear remains an expensive zero carbon option. The current price for electricity is approximately £83mWhr.

As the cost of Hinkley Point has increased, the backers have had to provide more funding. The souring of relations between Britain and China saw CGN stop providing any more money, leaving EDF to fund the shortfall. EDF has called upon the UK government to help out with the escalating cost but it has refused. EDF was fully nationalised in 2023, leaving the French taxpayer to pick up the tab for the cost overruns.

Like Hinkley Point, Sizewell was a joint venture between EDF and CGN but concerns over Chinese involvement meant the UK government took over from CGN in 2022. The cost overruns on Hinkley mean EDF wanted a different funding arrangement to avoid picking up the construction risk for Sizewell.

It will be funded using the regulated asset base model, which is the same as used for Thames Tideway; a surcharge is placed on electricity bills to fund the plant. EDF’s role would be to build and operate the plant without taking the construction risk.

A development consent order for the project was granted in January 2024 and the nuclear site licence approved in May 2024. The final investment decision will be made at the end of this year.

Sizewell C may cost less to build than Hinkley Point thanks to the experience gained constructing the latter, but the British consumer could end up paying more thanks to the different funding arrangement.

Prefabrication is a key part of the strategy to speed up construction. “The whole southern end of the project is effectively a manufacturing area,” explains Mike Dowling, Bylor’s operations lead for the nuclear island.

“There are a number of bunkers and factories where we make pools, liners and precast modules. Our ambition is to componentise and modularise as much as possible to minimise the volume of work taking place in the condensed centre of the nuclear island area.

“We are constantly learning lessons as we build unit one and are using the opportunity of the large crane to add more modular components to unit two.”

Increasing the size of prefabricated elements is being used to improve productivity on the second reactor. The equipment hatch, which will be used to install components including the reactor pressure vessel and steam generators, is fitted to the top steel liner.

On the first reactor this was welded in place after the liner was installed, requiring complex temporary works to support the hatch during welding. This slowed down adjacent works. For the second reactor, the hatch was welded to the second liner to be fitted on the ground. “We lifted the whole thing in one go, which saved us about 10 weeks,” Parsons says.

This approach comes with its challenges as the liner ring is 47m across, 18m high and weighs 401 tonnes in total. “It is an incredibly complex lift because the hatch is on one side so the load is asymmetric and needs to be balanced,” explains Andrew Jackson, technical and quality director for Bylor.

“The lifting equipment is asymmetric to match the load and weighs tens if not hundreds of tonnes. It’s a much bigger lift than you get on any other construction site. We had to do a very elaborate and carefully managed lift just for the lifting equipment and adjust this to be able to lift the main load.”

The concrete works are also moving more quickly on unit two. The foundation slab was delivered four months faster thanks to the experience gained on the first reactor and increased use of digital modelling. The steel liner rings are encapsulated in concrete with three lifts per ring which are poured in one go.

The area around the equipment hatch is particularly congested requiring that lift to be done in two pours on the first reactor. This was done in one go on the second thanks to the use of special construction joint methodology in combination with self compacting concrete.

The 15m-high stainless steel pools which house the reactor are filled with water to provide radiation shielding during refuelling. This means the integrity of the welds joining the stainless steel panels is critical.

The second unit pool is being welded in a concrete bunker using automated welding, unlike the first reactor pool which were welded manually, causing distortion and necessitating rework. The welding is taking place four times faster with fewer defects.

Radiography is used to check the integrity of the welds, a job that is easily done in the bunker as this provides the necessary shielding. Some of the elements of reactor one’s pools were welded in situ, requiring radiography testing in the reactor building, a job that disrupted other work while this was taking place. A greater proportion of the second reactor’s pool will be made in the bunker rather than onsite, reducing disruption and therefore saving time.

Ensuring that workers are sufficiently skilled to work on a nuclear plant has been another challenge. EDF has invested in three so-called “centres of excellence” which cover welding, electrical and mechanical skills. Everyone who applies to work at Hinkley is tested for competence on one of these centres.

“We want to make sure that someone who turns up and says they are a welder is a welder,” Parson says. The centres are also used for training so workers can gain new qualifications. Welders, for example, can gain nuclear industry specific certification.

Bylor has used the same process for the civil engineering works. “We assess all steel fixers coming in for competence,” Jackson says. “We have had to turn quite a lot of people away, although at the same time we have upskilled people, and we have had over 450 apprentices.”

There is also a training school for crane drivers including a simulator. Jackson adds that there have been special training courses for crane drivers given the complexity of some of the lifting demanded by the project.

Parsons says that EDF was aware that skills would be problematic and has taken on 1,300 apprentices in a bid to change this. “What EDF is trying to do is create a workforce that can build nuclear in the UK,” he says.

Hinkley Point is moving into the mechanical, electrical and heating phase of the work and Parsons hopes that this will dovetail with work starting at Sizewell as EDF does not want to lose trained-up workers.

“When the civils finish here (at Hinkley), we will see Sizewell kicking off. It’s a nice fit and is great for the UK government as we can drop all that learning into Sizewell. We will use a very similar supply chain and operational model at Sizewell as we have done at Hinkley.”

Applying the lessons learnt from Hinkley should see costs and programme reduced at Sizewell as there is no difference between the two apart from the groundworks, which are site specific. The current estimate for Sizewell is £20bn which is substantially less than Hinkley Point C.

Although the track record of EPR construction suggests that this figure is likely to go up, the experience gained at Hinkley Point and the fact there are no new regulatory hurdles to overcome mean that the odds of Sizewell staying closer to the current estimate are the highest so far.

Project team

Station designer, engineer and operator EDF

Enabling and ground works BAM/Kier

Main civil works Bylor: Bouygues/Laing O’Rourke JV

Marine works and tunnelling Balfour Beatty

Mechanical, electrical, heating & air conditioning The MEH Alliance: Altrad Services/Cavendish Nuclear/Altrad Babcock/NG Bailey/ Balfour Beatty JV

Reactor pressure vessel/steam generators Framatone

No comments yet