With new construction responsible for some 11% of global carbon emissions, the problem is clear enough. But what’s the solution? In the last of our four features on industry-changing innovations, we look at how the industry can mitigate the upfront embodied carbon impacts of construction

Last month’s decision by Michael Gove to refuse Marks & Spencer permission to demolish and rebuild its flagship store on Oxford Street marked a turning point for the industry. For the first time ever, a planning application was rejected on the grounds that a new-build would emit far more carbon emissions than a refurbishment unless the electricity grid was decarbonised.

M&S had argued that a new-build would have lower wholelife carbon emissions than a refurbishment but the Department for Levelling Up, Housing and Communities decided that, if the development was delayed until the grid was decarbonised, the upfront carbon of a new store would be “much lower or eliminated”.

In a year of tumbling records for high temperatures on land and in the sea, and extreme heat and wildfires in Europe, the time for urgent action on climate change is very much here and now. New construction is responsible for some 11% of global carbon emissions so the industry must act to reduce those emissions and, as the M&S decision demonstrates, is likely to be forced to do so via the planning system. In the last of our four features on industry-changing innovations as part of the Building the Future Commission, we look at how the industry can mitigate the upfront embodied carbon impacts of construction.

Reusing buildings

The most effective way to reduce upfront embodied carbon emissions from construction is to not build anything. Given that the built environment needs to respond to changing societal needs – and old buildings need to be periodically refurbished to keep them up to date and efficient – some construction work is inevitable.

The big London-based developers have already taken this on board and are making efforts to retain the frames of buildings where these have sufficient floor-to-ceiling heights, structural capacity and are in good condition, as the frame often includes 50% or more of the total embodied carbon.

Ideally other elements should be retained where possible – for example, up to 15% of embodied carbon is in the facade. British Land chose to carefully remove, refurbish and reinstall the 20-year-old facade of its 1 Triton Square office in central London rather than replacing it. Keeping the 3,000m2 facade saved 2,400 tonnes of carbon and 66% of the cost of a new facade. Replacing the double-glazed units ensured that the building was energy efficient too.

Occupier demand for low-carbon space and government moves to require all non-domestic buildings to have a minimum EPC B rating before these are rented out by 2030 is driving the retrofit and refurbishment of existing buildings. Simon Wyatt, sustainability partner at multidisciplinary consultant Cundall, says replacing the lighting, fans and improving the energy efficiency of mechanical systems will pay the upfront carbon back in a reasonable space of time, but he questions whether it is worth upgrading the building fabric.

“In order to get the best energy performance, you need to start doing work to the fabric of the building. And this is where – going forward – there is going to be a bit of uncertainty over the next five to 10 years as the embodied carbon of doing the works to improve the operational energy may not pay back in carbon terms,” he says.

>> Click for more on the Building the Future Commission

The uncertainty comes from not knowing how quickly the grid will decarbonise as carbon is being expended now on materials to save energy over 20 years, and the carbon impacts of that energy depend on how it is generated. This calculation is complicated by the fact that current grid decarbonisation assumptions assume energy efficiency improvements to buildings and, if people hold back on the grounds that the carbon payback does not stack up because the grid is decarbonising, the process will take longer.

Reusing materials

If the case for demolishing a building is overwhelming, the next-best option is to reuse the materials as this is less carbon intensive than reprocessing these into new products. Some building materials, such as London stock bricks and hard landscaping products, have been reclaimed for many years as these were easy to reclaim with a high value, making the exercise worthwhile.

There is growing interest in reusing a much wider range of materials, such as raised access flooring and structural steel. Recently, several London developers including Grosvenor and Great Portland Estates, have experimented with reclaimed structural steel for new-build projects. Because this is a nascent industry, sourcing the steel can be a challenge. Both Grosvenor and GPE reclaimed their steel from existing buildings within their portfolios that were due for demolition.

Audrey McIver, a director at multidisciplinary consultant WSP, sources reclaimed steel from a big scrap dealer called EMR and stockholder Cleveland Steel & Tubes, both suppliers certify the steel for reuse. McIver’s team have to match the section sizes in the design against the suppliers stock list.

The available steel sections are unlikely to exactly match the design, so it is a case of establishing a best-case match. Working out that best-case match for all the steel in a building is a fiendishly complex task, so WSP has developed a parametric modelling tool to simplify this job.

Another complication is that, by the time the building gets to site, the reused steel sections identified at the design stage may no longer be available. McIver says this is not necessarily an issue.

“The stockholders do have visibility of what is coming as they know their market and what is coming up for demolition. So we have a sense of what is more risky in terms of section size than others,” she says. “And what is the worst that could happen? We would have to use some new steel, which is what we would have had to do anyway.”

McIver adds that, in carbon terms, it is not worth using significantly heavier steel sections than called for by the design. “If the one that is available is 20% heavier than the most efficient new section, you are probably better off giving someone else a chance to use that beam, or sending it off to be recycled in the normal way, because the recycling is a very mature and efficient process,” she says.

David Watson, AKTII’s technical director and climate change lead, reckons reclaimed steel is a transitional phenomenon as steel production decarbonises. This is because old steel sections can be completely recycled into new ones.

“The carbon cost of reprocessing steel is going to come down to the point where any small amount of wastage when reusing steel is going to be difficult to justify,” he says. McIver adds that, as more buildings are refurbished rather than demolished, the supply could dry up.

Concrete is much more difficult to reuse than steel; the default is to crush it for aggregates. Gerry O’Brien, AKTII’s design director, says there is a trend toward cutting out whole pieces of floor slab for reuse because planners see this as a good thing.

“When you put in a circularity submission for a planning application, they don’t like the idea that you will reprocess the material. They would rather have it used as close to how exists at present,” he says.

O’Brien thinks this approach is problematic as crushed concrete is much more versatile than chunks of floor slab, which have to be transported and stored until the right use can be found. And aggregate for new concrete needs to come from somewhere.

“30% of the aggregates that we use in the UK every year comes from reprocessed aggregates,” he says. “If this wasn’t available, we would be digging 30% more out of the ground.”

Innovation could come to the rescue as the cement paste binding the aggregates could be reclaimed by extracting the un-activated cement in the concrete and reactivating the hardened paste.

What about the materials used for the fit-out and services? Wyatt cites reclaimed access flooring as a exemplar for these elements.

“This shows it has to be done professionally,” he says. “Suppliers take the flooring away, clean it up and make it good and provide a warranty. Agents are quite happy to point to a scuffed-up floor and say it has been recycled. Isn’t that a great story? That has been really positive and we need to see that across the wider industry.”

Wyatt questions why elements such as ductwork and cable trays are scrapped when these could be easily reused. “Ductwork and cable trays are generally melted down and recycled, but why are we wasting that energy and that carbon to do that when they’re perfectly functional as they are,” he asks.

Wyatt reckons that fancoil units could be reused too. “An office could have several hundred fancoil units. When there is a new fit-out, they are put in a skip and taken away. 80 to 90% of the embodied carbon is associated with the shell, the only thing that needs to be replaced is the controls, motors and the fan because these are much more efficient now. The rest of the fancoil unit can be retained.

“What we need to do is work with the MEP industry in the same way as the raised access flooring industry, so these are taken away by the suppliers, made good and reused.”

Wyatt adds that this could also apply to lighting and other services too. Material passports could make this process easier in the future as these would provide details of the components in a building, rather than needing to find out via surveys which are time-consuming and expensive.

Use materials more efficiently.

As materials are cheap and labour is expensive, many structures use material extravagantly to save time. For example, the flat slab is the default choice for concrete frames because these are quick to construct and the flat soffit simplifies the services installation.

Waffle and ribbed slabs were popular 50 years ago and used concrete more efficiently because these dispensed with concrete on the underside of the slab which were not contributing anything structurally. These can reduce embodied carbon by 20-30% but take longer to build and complicate the services installation.

The same is true of steel frames. Arup designed every structural element used on 8 Bishopsgate, a 50-storey office tower in central London, for its individual load which reduced steel weight by 25%. Avoiding long spans and irregular grids also makes a big difference.

“We’ve been able to get the embodied carbon of a number of steel buildings that we have been working on recently down from over 1000kg/CO2/m2 down to 600kg/CO2/m2 just by looking at the efficiency of the steel frame,” Wyatt says. “It’s making sure the structure is regular, the spans aren’t too long, and the depths are right. This reduces material and drives down cost.”

Ensuring that the structure is not overdesigned for the loads it will carry also saves carbon. This applies to services too. More rigorous building performance analysis of building designs helps here, for example using the NABERS design for performance process in addition to Part L.

Peter Fisher, the architect on Timber Square, an office building in Southwark, says the NABERS modelling enabled the team to reduce the number of heat pumps needed on the scheme. “On the first round of NABERS, we found the air source heat pumps would be operating at 20% of capacity at peak, whereas these should be operating closer to 60% [for maximum efficiency]. We were able to remove some of the air source heat pumps because they were never going to be used.”

Organisations that set performance standards for buildings are revising these to reduce the carbon impacts; the BCO published an update to its Guide to Specification this year which included adding smaller spans to the recommended range to help reduce carbon. Wyatt says CIBSE is working on guidance to reduce the oversizing of services and maximise performance.

Opting for low carbon over high-carbon material seems an obvious thing to do, but O’Brien adds a note of caution. “If you look at carbon intensity per tonne, the carbon intensity of timber is really low, the carbon intensity of steel is really high and concrete is in the middle. If you do it against Youngs Modulus [the material stiffness] then they would all be on the same line.”

In practice this means the carbon impact of a structure could be the same regardless of the choice of material because less high-carbon material is needed for the same performance. Distribution centre developer Prologis has focused on delivering low-carbon buildings for many years and has found a steel portal frame has less embodied carbon than a glulam structure and has the additional advantage that the steel can be easily recycled if the frame cannot be reused at the end of a building’s life.

Watson says architects are starting to think along these lines too. “Some architects are starting to look at embodied carbon per square metre of finish. Not per tonne of material, but per unit of performance. As structural engineers, we should be doing the same; choosing materials for strength and stiffness and durability. This is a much more informed approach.”

O’Brien says that all materials, including timber, should be used in the most appropriate and least wasteful way. Timber, for example, is ideal for housing as the spans are relatively short.

Reducing the embodied carbon of familiar materials

The substitution of cement with ground-granulated blast furnace slag (GGBS) and fly ash has become the default for many new developments, particularly ground works where the slower curing times are less of an issue. Half of the cement in a mix is regularly substituted with GGBS with up to 85% possible.

The downside of these materials is that GGBS is a byproduct of carbon-intensive steel production, and fly ash of coal-fired power stations, which have all but been phased out in Britain. If the steel industry can move away from blast furnace production, the supply of these materials will eventually dry up.

A lot of work is focusing on finding alternative ways to reduce the carbon impact of concrete. Because cement production releases carbon dioxide regardless of how the kiln is heated, the cement industry is looking at carbon capture and storage (CCS) as a solution.

Heidelberg Cement has started building the world’s first industrial-scale CCS cement facility in Norway. Others are investigating alternative ways of reducing the carbon impacts.

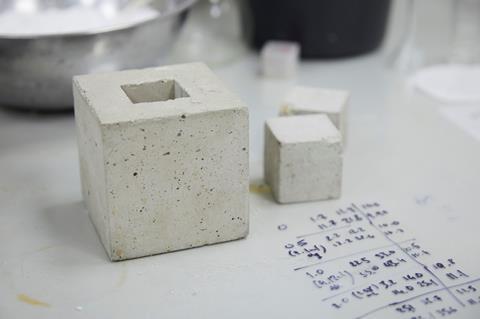

The National Graphene Centre at Manchester University researches practical applications for graphene and sister organisation the Graphene Engineering Innovation Centre commercialises these. It is working on a graphene-enhanced cement called Concretene which can potentially use 30% less material for the same performance.

“You potentially can get a product that is cheaper and has lower CO2 emissions, but also has very good performance. Not only do you get the mechanical strength, it cures more quickly, it doesn’t crack and there is no need for expansion joints,” explains James Baker, the centre’s chief executive.

He says that, if the graphene is properly dispersed throughout the mix, less than 0.1% of it is needed. A big challenge is dispersing such a small amount of graphene evenly throughout large volumes of concrete.

Baker says the secret of Concretene is an additive which disperses the graphene evenly through the mix and gives consistently good results. The cost of graphene is coming down and Baker points out that, while Concretene will cost more than standard concrete, it should work out cheaper because up to 30% less material is needed.

As part of the process of getting the product certified, it has been used on projects including a layby, a gymnasium and a housing development. Baker concedes that getting the right approvals will take time and envisages it being used initially for simple structures such as roads, pavements and single-storey buildings.

Watson and O’Brien are particularly excited by a product called Seratech, which came out of work done by Imperial College London. This takes magnesium silicate and combines it with CO2 to produce silica and magnesium carbonate.

“Silica is chemically very similar to fly ash and the like, so you put that in your concrete to replace a proportion of the Portland cement. It is a really familiar chemistry and gives you a concrete with good strength and durability properties,” explains Sam Draper, the CEO and co-founder of Seratech. The magnesium carbonate can be used to produce a low strength concrete for block or board manufacture.

The beauty of this process is the silica manufacture balances out the CO2 from the cement production. “The process used to produce the silica sequesters CO2,” Draper says.

“A mix that is 65% Portland cement and 35% silica is in line with existing standards for using fly ash. All the emissions from making that Portland cement is being sequestered to produce the silica which means the mix is nominally net zero.”

Draper says the testing done to date shows that the product has better early strength than concretes made using fly ash or GGBS.

The big advantage Seratech has over similar products is that it meets the chemical definition of a pozzolan, that is to say a material that does not have any cement content but behaves like one when mixed with water and Portland cement. The only difference is the silica is an engineered product, so Draper is in conversations with the Mineral Products Association and British Standards Institution to get their approval.

“Hopefully we will get a green light from them, which means it is already approved as an existing cementitious material.” And it can be used in the same way as existing concretes using the same equipment. Draper says it should cost the same or be slightly cheaper than current products as the raw materials are abundant and cheap.

The next stage is to prove the product in pilot projects with which AKTII are helping. Draper says that, once Seratech has been proven, it will put the business in a better position for getting the interest of cement manufacturers who could provide the CO2 for the process and reduce their carbon footprint.

Draper says the CO2 produced from brick kilns would also be a good source. He adds the product could be available as early as 2026, although more realistically by 2027.

The steel industry is experimenting with direct reduced iron, a refined iron ore for making steel using an electric arc furnace which can be powered using renewable energy. The problem is the direct reduced iron is produced using natural gas which means the process is not much lower carbon than simply using iron ore in a blast furnace.

Tata is experimenting with using hydrogen in place of gas to produce the direct reduced iron and a company called H2 Green Steel is building a plant in Boden, north Sweden, which it says will produce 95% less carbon emissions compared to conventional steel with a production target of five million tonnes of steel a year by 2030.

What would help drive change?

There are plenty of ways of reducing the carbon impact of construction materials including some promising innovations. But the construction industry is slow to embrace change and time is running out. So what would speed things up?

Regulation is one answer. A group of industry experts including Simon Sturgis, an architect and specialist in wholelife carbon, have created a new building regulation called Part Z to regulate embodied and wholelife carbon.

It proposes that all buildings over 1000m2, or housing schemes with more than 10 units, submit mandatory wholelife carbon assessments and upfront embodied carbon calculations. Initially there would not be limits for wholelife carbon but upfront embodied carbon would be subject to limits.

The proposal enjoys widespread support including from investors, developers, architects and contractors. The GLA already requires wholelife carbon assessments of major schemes, so it seems inevitable that this will extend nationally over the next few years through building regulations. The big unknown is what limits would be set by the government – it is likely the limits would be initially relatively generous to allow smaller, regional clients and contractors to adapt to the new rules.

Much of the current drive towards net zero is being led by financial institutions who are in turn driving change in the industry. For Wyatt these institutions are at the forefront of change. “The financial sector is leading, occupiers and other organisations are following, and the government is trailing behind,” he says.

As financial institutions widen the scope of their carbon reporting, they include the impacts of so-called scope three emissions; indirect emissions not directly controlled by that institution. This will impact directly on the development and construction industry as financial institutions seek to reduce their scope three emissions.

This could include the embodied carbon impacts of the buildings financed and occupied by those institutions. In time this could mean financial institutions favouring refurbishments over new buildings or buildings with demonstrably low upfront embodied carbon.

Taxation is another lever. “Taxation on materials is generally quite low, which drives us towards primary material use,” Watson says. “If you want to extract materials from buildings and reuse and repurpose these, there is a lot more labour involved. Labour taxation is proportionately higher than on materials.”

Although adjusting this dynamic sounds logical, it could be challenging as it could push up prices of items considered essential by many, which would impact those on low incomes who proportionately do not pay much income tax. A carbon tax would also be controversial as it would inevitably mean bumping up the price of gas and motor fuel, something which past experience shows would be deeply unpopular with the electorate.

A less controversial move could include adjusting taxes such as VAT to provide financial incentives to favour refurbished products or buildings. This lever could also be used to promote the use of goods as a service rather than outright purchase.

Suppliers could lease products as a service rather than selling these outright, which would incentivise them to refurbish rather than renew because this would make financial sense.

More from our Building the Future Commission series on innovation

>> Are platforms and procurement the answer to MMC adoption?

>> Everything you wanted to know about MMC but were afraid to ask

According to O’Brien lump sum procurement stifles change. Designing out carbon involves more upfront work, which adds cost and does not sit well with a lowest cost mindset. And transitioning to lower embodied carbon inevitably involves a degree of risk as it involves doing things differently.

By the time a contractor is appointed on a project, the scope of work and price is fixed so the contractor understandably wants to use tried and tested forms of construction using a supply chain they are familiar with. O’Brien cites the example of the UK Bloomberg HQ in the City.

“It isn’t accidental that on Bloomberg, which was construction management with the client making the decisions continuously throughout the process, there were bucket loads of patents because they had proper opportunities to embed innovation throughout the project,” O’Brien says. “That is frequently made inaccessible because of the procurement route and that discussion around risk.”

Despite this there is an inexorable drive towards lower carbon construction. Many developers are already prioritising refurbishment over new-build and the M&S decision, whatever the motivations behind Gove’s announcement, will only accelerate that. Regulations and pressure from the investment community mean the construction industry will have to respond and negotiate a path towards lower embodied carbon buildings.

There is high demand for reclaimed steel and raised access flooring to the extent these products command a price premium which will prompt other sectors to follow. The challenge will be extending the work done by the big London developers and enlightened clients to the wider industry. Although this will take some time, the path blazed by those industry leaders should make the job easier.

No comments yet