It has become a cliche to suggest that to get the best ideas a designer must 'think outside the box' but sometimes it is appropriate to look beyond the building and review the nature and origin of the energy supplies delivered to the project.

We should ask what environmental impact has been created in order to get these utility services to the boundary of our site. Fundamentally, can there be a more environmentally benign approach to delivering the infrastructure services?

Most of the electricity generated in the UK has a primary fuel efficiency of 35%-45%, that is to say, most of the energy available in the primary fuel is rejected as waste heat. Furthermore, a large proportion of the power stations in the UK use gas turbines, fuelled by natural gas, which is a premium, relatively clean fuel. This is an energy source that also has a range of other extremely useful applications for which its characteristics are difficult to replace.

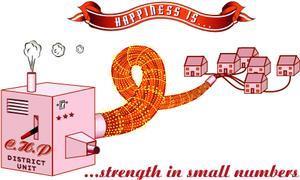

For large volumes of this fuel to be exploited purely for power generation at such low overall efficiencies could be argued to be a flagrant use of a limited natural resource. There is a simple way of getting more utilisation of our primary fuels and that is by cogeneration, otherwise know as combined heat and power (chp). Figure 1 shows a schematic comparison of the conventional energy supply scenario and the distributed energy approach, which links a number of buildings together using district heating/cooling and a private wire network emanating from an energy centre.

By recovering and utilising the heat produced from the electricity generation process, chp plant can have a total fuel conversion efficiency of over 80%, as shown in figure 2. All reasonably sized projects, say greater than 1000 m2, can consider chp as a partial or total replacement for conventional utility energy supplies (micro-chp technologies, when they have become more developed may make even smaller scale projects feasible).

There are already many successful chp/community heating projects in the UK that are delivering cost effective on-site heat and power. Such projects include many university, hospital, leisure centre and industrial sites but there are also increasingly housing and mixed-use developments such as the Sheffield City heat and power scheme, and the Greenwich Millennium Village and Barkantine scheme in east London.

However, generally the market penetration is small in the UK. CHP provides only around 5% of the power generation in the UK, by comparison the Netherlands, Denmark and Finland each use chp to supply more than 35% of their electricity generation. The global impact of the inefficiency of traditional power generation is enormous. It has been estimated that the overall worldwide waste of energy arising from central power stations is about the same as the total amount of energy consumed by the global transport sector.

The energy centre, which is effectively replacing the traditional inefficient power station, can be positioned in one of the occupied buildings or as a stand-alone construction, on or near the site to be served. Typically, the chp plant is a gas-fired reciprocating engine or gas turbine and will be sized to serve at least the base heat load requirement.

The heat to power output ratio is approximately 2:1 but it does depend on the size of the chp unit. Larger units tend towards a larger proportion of electricity output. Some projects may use the chp plant to meet a large proportion of the site electricity demand and the resulting heat output may thus exceed the base hot water load.

This situation is viable when the chp plant generates electricity more cheaply than the tariff charged by the conventional utility company. The penalty in this scenario is that the surplus heat has to be rejected to the environment, unless there is of course a useful application for the heat such as space heating or absorption cooling (ie a tri-generation system). Mixed-use developments tend to even out the energy demands, optimising load factors and improving the overall efficiency of the plant.

Sources and sustainability

One of the key features of distributed energy schemes is that a wide range of energy sources can be considered. At the moment the balance in tariffs favour natural gas as the preferred fuel for most chp applications but where a natural gas network is not available lpg may be appropriate. In the longer term when natural gas becomes more depleted other fuel sources for cogeneration such as biomass (wood chips and pellets), biogas, landfill gas and refuse will be more economic, especially as taxation is likely to be stacked in favour of renewable energy sources.

Alternative thermal energy sources for district heating will become more prominent including large scale solar collectors, which have been tried on a district scale in Sweden and Denmark. In addition, aquifer thermal energy storage looks like it could have a significant role in future distributed energy schemes where the local geology is appropriate. There are already over 100 distributed energy projects using this technique in the Netherlands with operations in almost every major city.

In a typical aquifer thermal energy application for commercial buildings the district heating is provided by a heat pump using the ground water as a low temperature heat source. In summer the ground cold store is used directly for cooling, thus avoiding the need for compression chillers.

The flexibility of being able to change the primary fuel source in a local energy centre to suit changing economic and resource availability conditions, means that investing in more distributed energy networks now will effectively improve the security of supply of power, heat and cooling in the future. Conversely, continuing to design developments that are dependent on the grid for general power supply, compressor chillers for cooling and limited natural resources for heating means that there will be greater technical barriers later to adapt buildings to cope with different fuel availability scenarios.

The benefits of having chp with associated distributed energy systems can be summarised by looking at the three aspects of sustainability ie economy, environment and society. All aspects should be considered in an appraisal.

Economic benefits:

- Lower whole-life cost scenario compared to supplying project with conventional utilities.

- Lower energy costs for end-users (although this is sensitive to tariff fluctuations).

- Lower end-user maintenance costs (especially when comparing the maintenance and gas safety inspections required for a multitude of small boilers against a centrally managed plant).

- Attractive to leasing companies who will consider capital funding of the project in return for 15-25 year operating lease agreement.

Environmental benefits:

- Reduced depletion of fossil fuel resources

- Lower carbon dioxide and NOx emissions (depends on fuel mix).

- Greater opportunity to utilise alternative energy sources such as biomass, solar and refuse.

Societal benefits:

- More affordable heating means less risk of fuel poverty.

- Increased security of energy supply.

- Virtually trouble-free heating system from the perspective of the end-user.

- Construction of the energy centre and the distribution network improves local employment and training opportunities and engenders community pride/local empowerment.

The future

A low energy approach should not be limited to the design of the building and its services. It should also include an appraisal of the infrastructure. Projects that use combined heat and power plant, district heating/cooling and private wire networks can significantly reduce primary energy consumption. Life-cycle costing can be used to assess the economic viability of local distributed energy systems, and optimise plant sizing.

In recent feasibility studies it has been demonstrated that distributed energy systems can deliver heat and power to customers at tariffs up to 10% lower than conventional utility scenarios and carbon dioxide emission savings of 0·75 million tonnes per annum. What's more, there are significant carbon emissions savings and the infrastructure becomes more readily available to diversity in fuel supply.

Downloads

Figure 2: Conventional versus chp energy conversion efficiencies.

Other, Size 0 kbFigure 1a: Comparison of conventional and chp distribution

Other, Size 0 kbFigure 1b: Comparison of conventional and chp distribution

Other, Size 0 kb

Source

Building Sustainable Design

Postscript

Ashley Bateson CEng, MCIBSE, MInstE is an associate with Fulcrum Consulting.

No comments yet