It is certainly happening at TPS Consult, a subsidiary of Carillion. TPS Consult's Object Technology package provides a single interface for the whole supply chain based around a 3d model of the building. The software covers the four stages of the life cycle of the building: design; construction and manufacture; operation and maintenance; and demolition.

Steve Jolley, a director with TPS Consult says technologies like this will help improve the whole construction process: "One of the reason's for using Object Technology is to increase profitability for everyone concerned. For clients, because they should be getting buildings produced faster and getting them to market quicker, and for everyone else involved because with this software, we should be able to do things quicker, smarter and to a higher standard." Jolley claims that TPS has been using Object Technology to differentiate at bid stage and win work. "It improves stakeholder awareness, it ensures the solution meets their expectations and it helps us provide an integrated approach to our complete supply chain." So how does this new technology work, and how is it different to building model packages that have preceded it?

"The idea of Object Technology is that it produces a database driven intelligent object," says Jolley. The advantage of this 3d model over traditional 2d drawings is that each object knows what it is and how it should behave in the surroundings it has been placed. "With a drawing, every time you want to represent a door or a window from a different angle you have to redraw it. In 2D you can save it as a block, move it around and attach information to it, but it has no intelligence other than that. An object knows how it should be represented, it knows how it should appear and how it should interact with the world around it."

The software places the object model of the building at the centre of the project. To that can be added all the information and data necessary for everyone at each stage of the project to do their job. The central model is just the starting point for the numerous other activities that need to be undertaken pre-construction. Jolley says: " Other technologies can read these object models so other analysis can be carried out. You can do structural analysis, virtual environment analysis. From an object model, you can export a file to Navisworks, a clash detection package, and make sure there are no pipe runs or ductwork that clashes. At the moment there isn't one product that does everything, it's a matrix of products that are pulled together to deliver the overall solution."

A clearer picture

Another key advantage of Object Technology, says Jolley, is that it is much easier for clients and contractors to comprehend. "Everyone in the supply chain can understand a computer model in hours rather than days for a drawing. If you're in the procurement phase or construction phase, the model should be passed on to the fabricator. There's no point giving them drawings because the model is the real data."

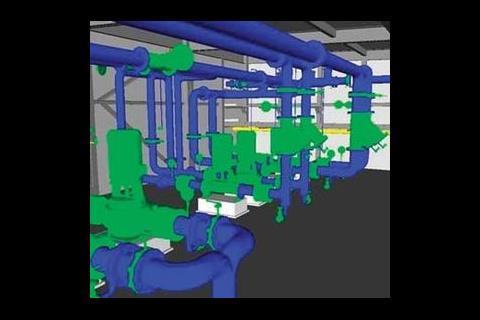

Howard Passingham is cad manager with Crownhouse, the fabricating and installation arm of Carillion. He says that the 3d model creates a greater awareness of the space his team has to work with. "An object model allows us to see very quickly how the designers co-ordinated the space in the building. With a 2d drawing, it's sometimes difficult to get inside the thinking behind how the designers have laid the plant room out and the reasons for running the services in a particular area."

The use of a single 'live' project model for the whole supply chain also means that everyone can see what the building looks like and knows that what they are being asked to do will work, as Passingham explains: "We walk our supervisors around the building, so its not just us and the designers that know what's going on, but the guys who are actually installing it. They can have a look at a very complex area of plant room and get a feel for it straightaway."

Because every 'object' put into the model knows what it is, and how it should behave, the contractors can see that what they've been asked to install will function properly. Passingham says: "A duct knows it's a duct, and if we take it through a fire rated wall it's aware of that. With the supply chain we use, we can pass that model onto the ductwork contractor and it saves the time it takes to redraw everything throughout the stages. We know that the model is built as the building will be, the model becomes part of the process rather than the stop start nature of using drawings."

For the operation and maintenance of the building too, the object model can prove a valuable asset. "Only too often we hear of paper manuals that are very rarely used. With the model, the operator can interrogate it. There's a bit of learning to be done, but it doesn't take long to work out how to navigate around the model and find things." The object model can become a useful tool for the whole life of the building. "If we can pass over a building with the virtual building, and all this information attached to it, it becomes a really important asset for the next owner."

The success of Object Technology is dependent on co-operation from the supply chain. The designers and installers need the rest of the chain to provide information in a format understood by the object model. "It's something as an industry that we need to address. Where manufacturers are producing information in the traditional way – manuals or 2d cad drawings, we need to ask them for a little bit more, and I think some of them are doing that," says Jolley.

For Object Technology to be used successfully it is essential first to make sure that the employees know how it works, and why it is being used. "People are the most important component of the whole process," says Jolley. "Without their understanding, they can stop this whole movement so if you're going to employ object technology in your organisation you need a training strategy."

Part of this training is to make sure that the people in the organisation are able to take a step back from the process and see that what they are doing is having a benefit for the whole project. "Training people in the overall process means that they're not blinkered into just what they're doing. They have to focus on it and make sure they deliver in terms of efficiency, but just by taking a step back to a position where they can take a view of the whole process, they can see that by changing slightly, they can benefit the whole industry."

There is also a need for the idea behind the use of the object model and this new way of sharing data, to be reinforced at every stage of the project. "It has to be explained why you're using it every step of the way because it's easily forgotten and people will always revert back to what they have done before."

The advantages of using object technology are evident when the process is laid out in diagrams and accompanied by several impressive 3d visualisations but to be successful, it requires a change in working practices and the way information is supplied.

This will be the hard part for Jolley and his colleagues, but he is confident that others will see the benefits: "We need to influence as much of the supply chain as possible. If we're using this type of technology on a project, they must all understand why we're using it. We've also got to influence the industry and convince them that this is the right way forward. We want object technology to be seen as something that is changing the industry for the better."

Downloads

Object Technology

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet