There is more to a low-carbon window choice than whether you opt for double or triple glazing

The latest research released by Inspired Efficiency, a new energy, sustainability and carbon consultant, and resource-efficiency and footprinting expert Circular Ecology shows that triple-glazed windows aren’t necessarily the lowest-carbon option. Focusing on other issues, such as the type of gas between the panes of glass, how the windows are positioned in the wall and wider energy-efficiency measures in the building, reap larger improvements.

When it comes to glazing for windows and doors, there is a natural perception that a lower U-value is always better, but this isn’t necessarily the case. Triple-glazed windows, for example, have an additional layer of glass, but also a second pocket of gas in between the glazing panes. This results in lower emissions in operation, but comes at the price of increased embodied carbon.

Craig Jones, director of Circular Ecology and author of the Inventory of Carbon & Energy database, says: “Embodied carbon is the amount of carbon released in the manufacture and transportation of a product. It’s important to consider how much extra embodied carbon is required to produce triple-glazed windows and to compare this with the savings in operation”.

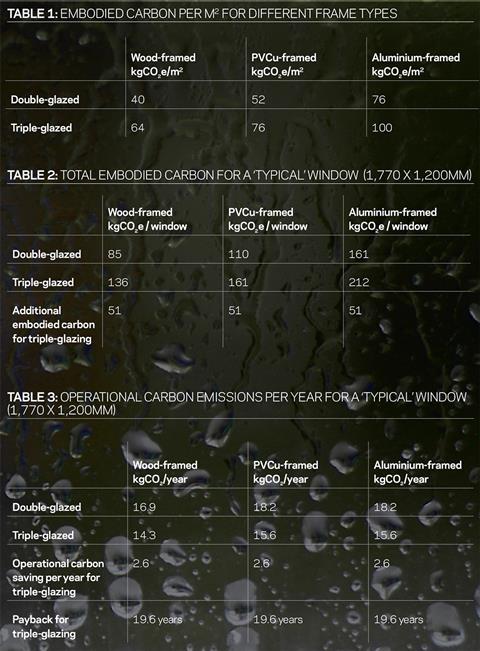

The embodied carbon of glazing units depends on a number of factors, such as the ratio of visible frame to glass area and the choice of frame type, such as PVCu, aluminium or timber. The research shows that wooden frames are, as would be expected, the lowest embodied carbon option, at 40kg CO2e per m2 of double-glazing. This is followed by PVCu at 52kg CO2e per m2, and finally aluminium frames at 76kg CO2e per m2. The triple-glazed options come with an embodied carbon penalty, with 59%, 46% and 31% higher embodied carbon than the wood, PVCu and aluminium double-glazed units respectively. The higher embodied carbon was compared with the reduction in operational carbon to see if they pay back within their lifetime (see table 1).

If we apply this to an average domestic window as an example (say, 1,770mm x 1,200mm), then the total embodied carbon for each option can be calculated (see table 2).

The U-value for a timber double-glazed window will depend on a number of factors - frame design, ventilation, type of gas within sealed units, as well as the number of panes of glass - but for the purposed of this calculation we will take it to be 1.3W/m2/K, and a triple-glazed timber window with the same gas fill as around 1.1W/m2/K. There is a wide range of window designs and specifications on the market that can provide substantially lower U-values than this, depending on the other factors.

Table 3 shows the carbon emissions due to the heat loss from this “typical” window within a domestic property heated for eight hours a day, seven days a week and six months of the year - keeping all other factors the same across all window types. This indicates that it will take around 20 years for triple-glazing to pay back in embodied carbon terms. Not quite the obvious choice that many think.

In carbon terms, the impact of the frame choice will have more significant considerations. By choosing timber over PVCu, one can save 25kg/CO2e - in other words, 10 years’ worth of operational carbon.

When choosing glazing, specifying the best gas within the sealed unit can have more of an impact than whether it is double or triple-glazed. A window with air-filled double-glazing will have a U-value of around 1.7 compared with the same window with an inert gas fill having a U-value of 1.3, an improvement of 0.4. That improvement in U-value is greater than going from gas-filled double glazing to triple-glazing, which will only improve the U-value by 0.2.

When considering replacement windows in properties, choosing the lowest-carbon specification of window can be wiped out by incorrect installation. Installers of replacement windows find it easier to screw through the side of the unit into a solid wall structure, which is typically the outer leaf of the cavity wall. This can leave the back corner of the cold outer leaf of the wall running around the side of the window on the inside of the property, creating a cold bridge. This frequently causes a narrow band of mildew to form around window reveals. While it is a little more involved to do so, installing the windows so that the centre line of the glass is in line with the centre line of the cavity will produce the best results.

There are many options that are marketed as the “obvious low-carbon choice”. But as this example shows, specifiers need to have a complete understanding of the benefits against the operational reality, as well as the needs of the occupier.

Craig Jones is director of Circular Ecology and Matthew Fulford is director of Inspired Efficiency

4 Readers' comments